Which is better offset or screen printing? The choice of offset printing or screen printing depends on the specific printing needs and application scenarios.

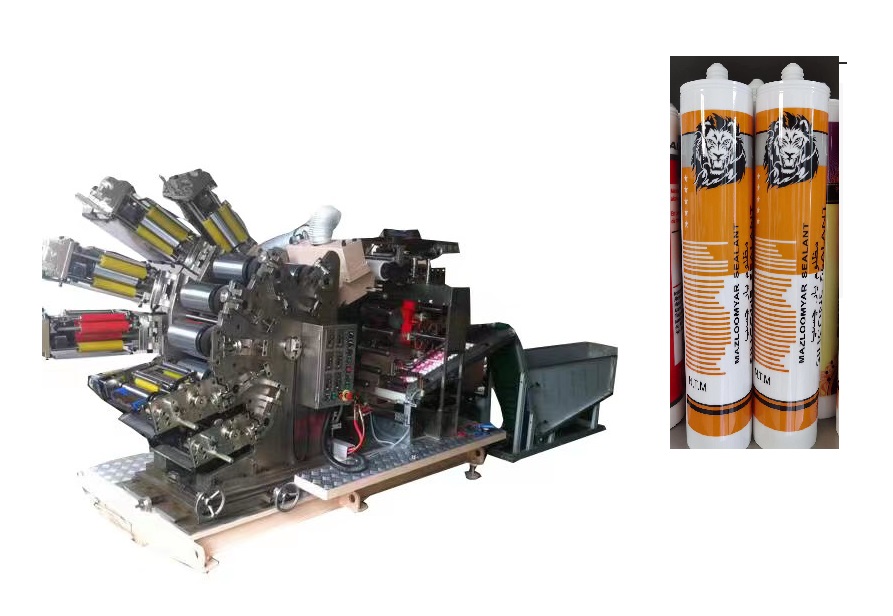

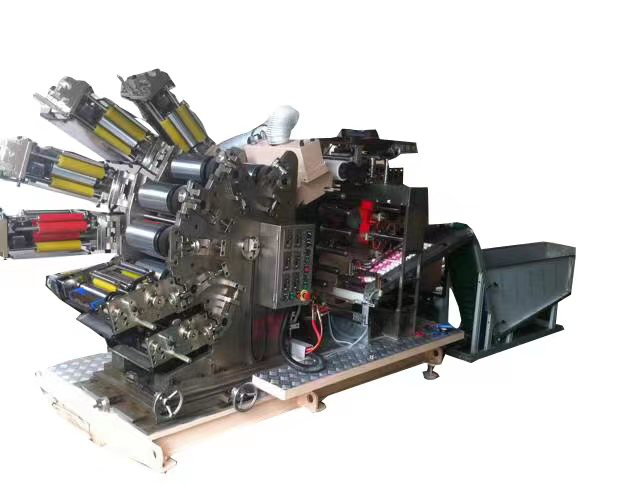

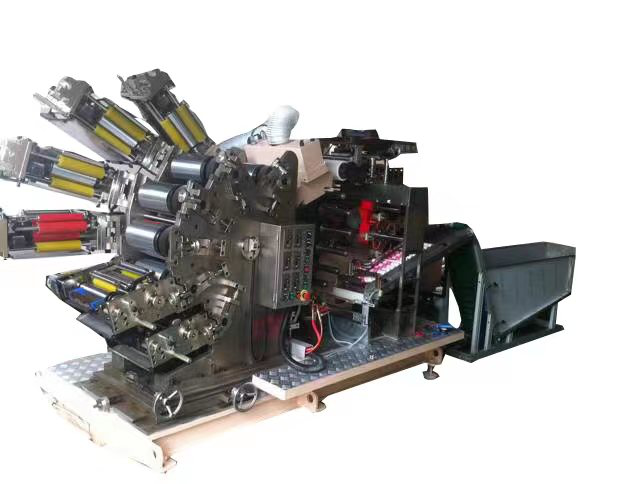

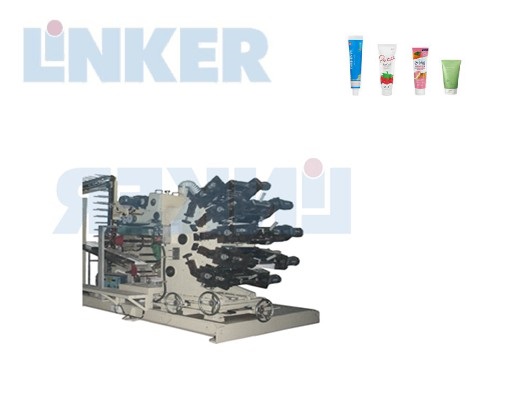

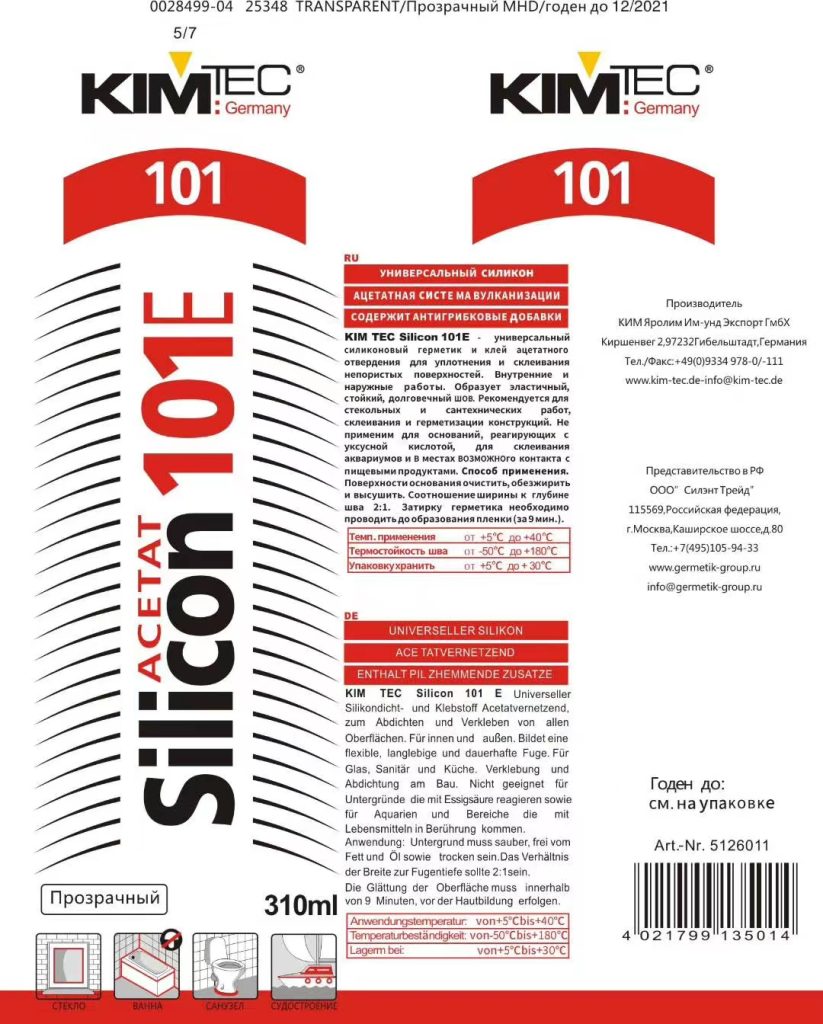

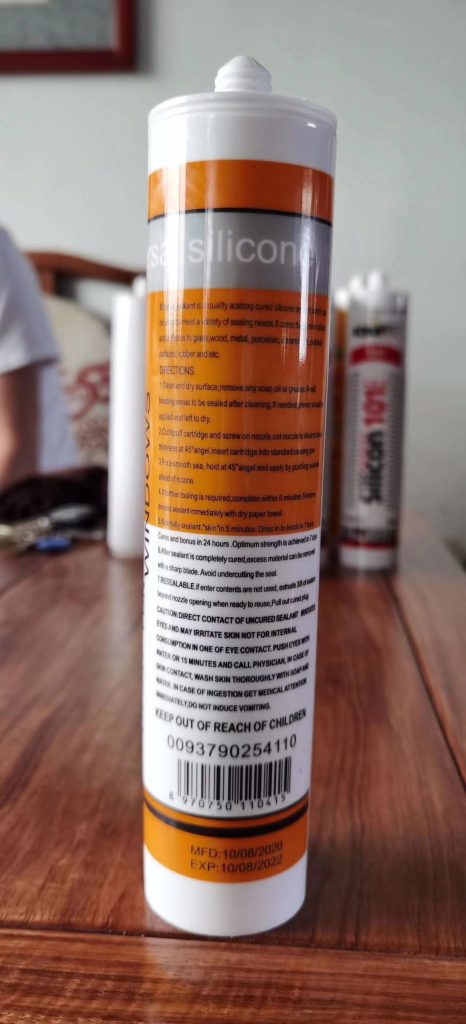

Offset printing is suitable for printing ordinary color rich, colorful color products, can make up for the uneven surface of the substrate, so that the ink is fully transferred, reduce the transfer of water on the plate to the substrate. Commercial Offset printing products are generally bright color, fine dot, very natural. It is suitable for paper materials, printing ink is easy to dry, suitable for the small number of customized products, ink is not large and want to be cheap. We have 1-8 color offset printing machine for soft tube and hard tube. Soft tube used for cosmetic tube, hard tube can use for glass cement. This machine is also suitable for bottle, cup, lip gloss bottle or any tube and bottle offset printing. Six color offset printing machine is the most popular product welcomed by customer. The difference of soft tube and hard tube printing machine is only the length of dry oven. The soft tube use long oven 8-9 meters, the hard tube use the short oven 2-4meters.

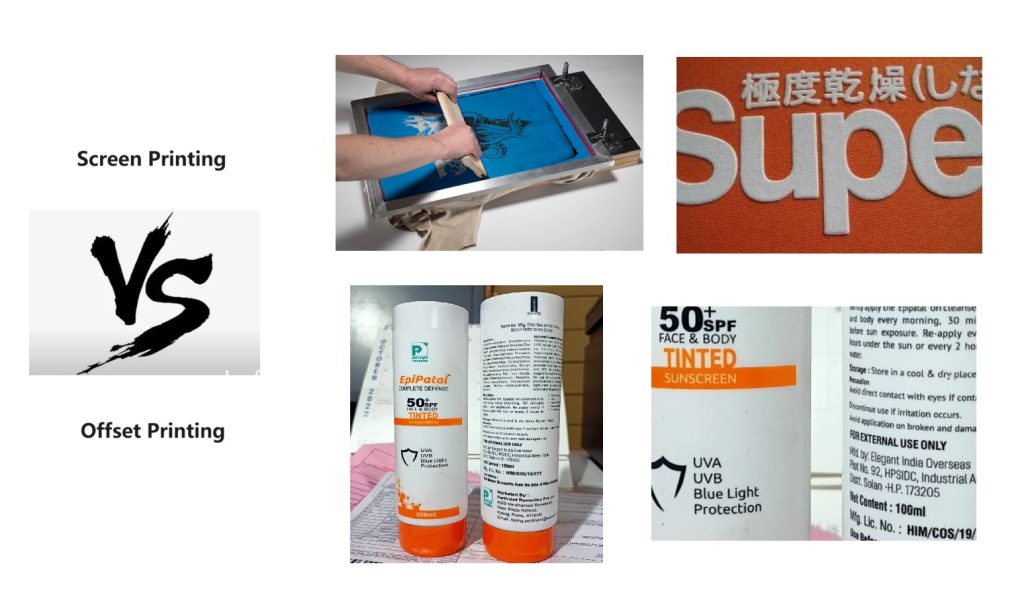

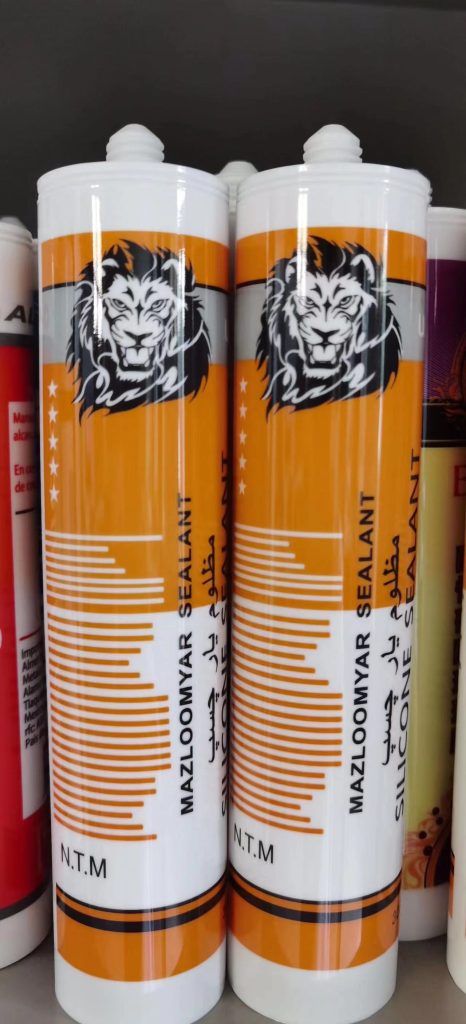

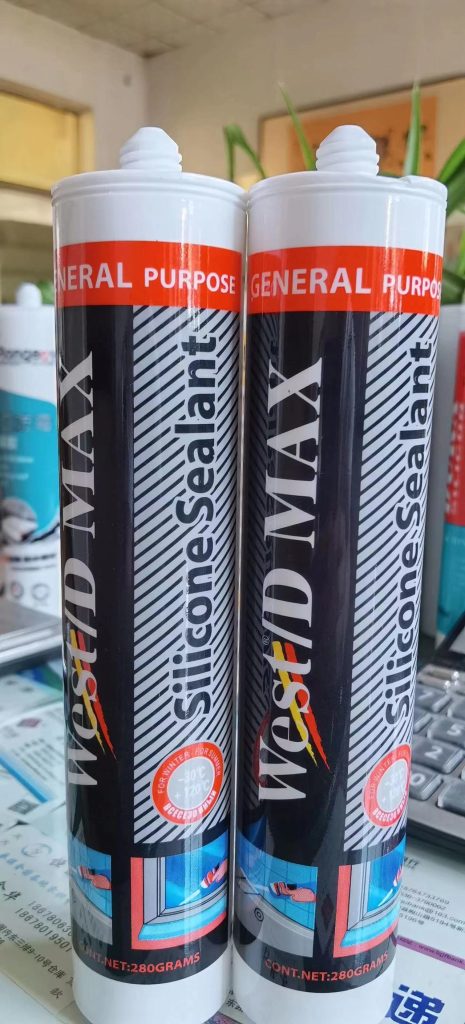

Screen printing is suitable for printing monochrome, two-color, three-color, thick ink, a small number of cases. The ink layer of screen printing is relatively thick, the color concentration is strong, the color block of printing is strong, but the dot line is poor, and it is suitable for printing panels and other products. There is no screen printing dot, and there will be some non-smooth edges when you look carefully, but the common monochrome simple graphics and text can be screened.

In terms of costs, UV printing printing costs are usually higher than offset printing.

What’s difference between offset printing and screen printing?

First, the process is different

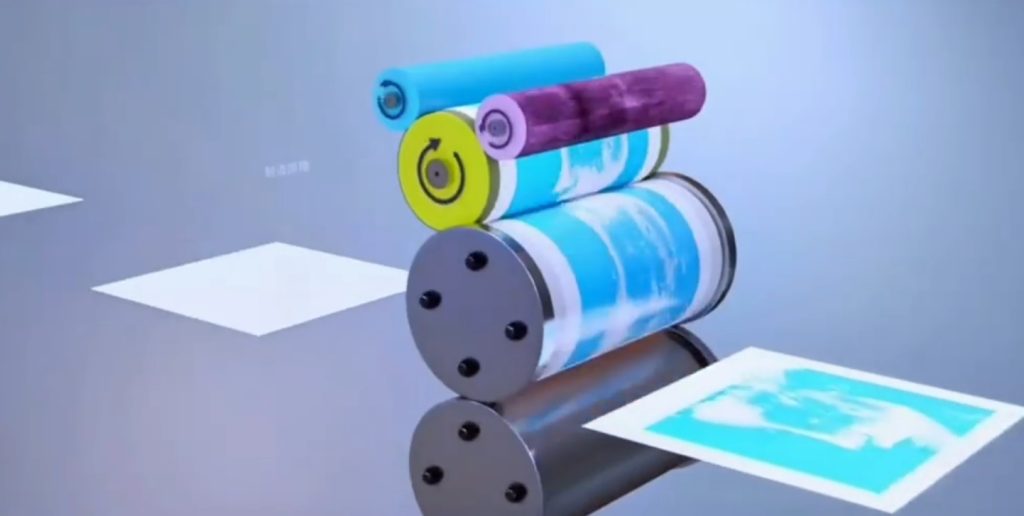

Offset printing is a kind of flat printing technology, the use of printing plate bump and height to achieve the effect of printing images, with the advantages of fast printing speed, high image quality, suitable for mass printing. Screen printing is a kind of mesh printing technology, through the holes of the mesh plate to control the flow of ink, can print a variety of shapes of patterns, suitable for printing curved, convex and uneven items.

Two, printing materials are different

Offset printing materials usually include printing plates, printing inks, printing paper, etc. The printing plate uses aluminum plate or chrome plate coated with photosensitive adhesive, and the printing ink uses water-based ink or oil-based ink. Screen printing materials include mesh plates, inks, gauze and printing items, inks can be screen ink, UV ink and so on.

Three, printing effect is different

Offset printing technology is suitable for mass printing, the printing effect is more delicate, the image clarity is high, suitable for printing pictures and text. However, for items with more curved or convex surfaces, the printing effect of offset technology is not as good as screen printing technology. Screen printing can use the characteristics of the mesh plate to print on a non-flat or convex surface, while its printing effect has a heavy sense, suitable for printing logos, trademarks and brightly colored patterns.

Different applications

Offset printing technology is widely used in the printing of books, magazines, posters, business cards and other flat prints. Screen printing technology is widely used in printing plastic products, glass products, metal products, electronic products and other non-flat printed matter. Screen printing technology is also widely used in printing T-shirts, ribbon and other textiles.

Conclusion

In general, offset printing technology and screen printing technology have their own scope of application, and the choice should be determined according to actual needs. For the need to print large quantities of flat prints, offset printing technology may be more suitable; For occasions where items of different shapes and materials need to be printed, screen printing technology is more suitable. If you need to print bright colors, fine dot products, and have high cost requirements, offset printing is a better choice. If you need to print monochrome or simple graphics, text, and have high requirements for the thickness and color concentration of the ink, screen printing is more suitable.

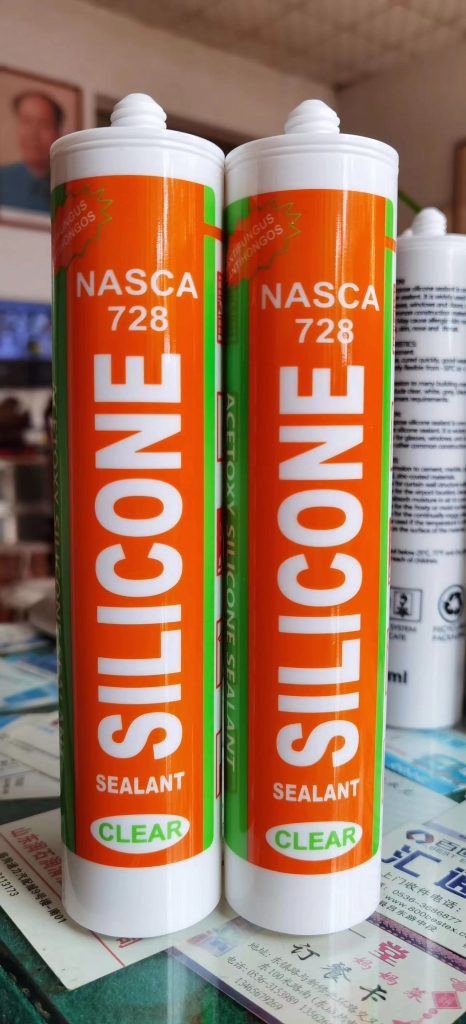

Samples of offset printing on soft tube:

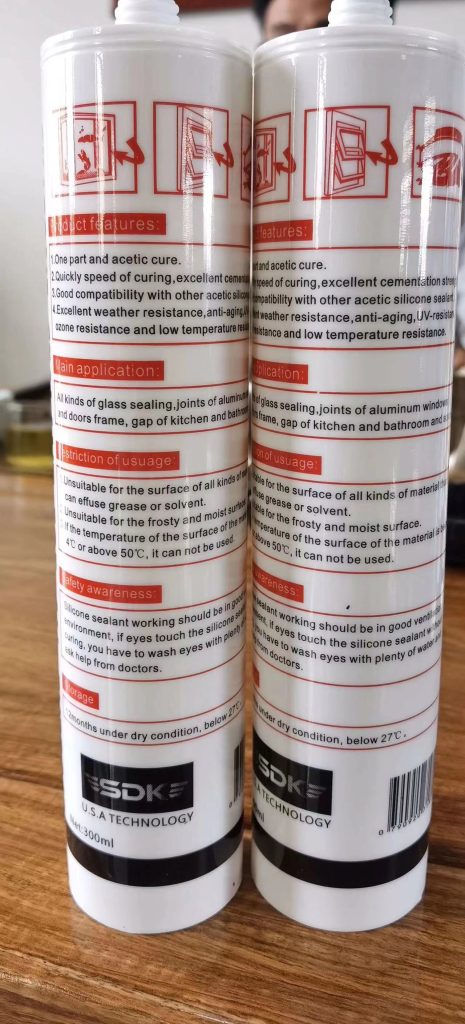

Sample of Screen Printing on screen printing: