1.1 Composition and characteristics of packaging machinery

The national standard GB/T4122.2-2010 “Packaging terminology Part 2: Machinery” defines packaging machinery. Packaging machinery is to complete all or part of the packaging process of the machine, the packaging process includes forming, filling, wrapping, sealing and other main packaging processes, as well as its related before and after the process, such as cleaning, drying, stacking, sterilization, bundling, packaging, disassembly, labeling and other packaging processes, transfer, sorting, printing, metering and other auxiliary processes.

1.1.1 Composition of packaging machinery

The necessary condition for product circulation is packaging, and packaging machinery is the fundamental guarantee for product packaging to achieve mechanization and automation. Packaging machinery belongs to the category of light industrial automatic machinery, because of the variety of products and applications of its packaging, so that its product types and complex structure, and new packaging machinery with social needs continue to emerge, it is difficult to classify their composition. However, through the analysis of the working principle and structural performance of a large number of packaging machinery, the common points of its composition can be found. That is, packaging machinery is composed of eight parts: packaging material arrangement and delivery system, measurement and delivery system of packaged items, main transmission system, packaging actuator, finished product output mechanism, power and transmission system, control system and fuselage

(1) Packaging material arrangement and delivery system

Packaging materials arrangement and delivery system is the packaging materials (including rigid, semi-rigid, flexible packaging materials and packaging containers and auxiliary materials) for a fixed length cut or arrangement, and one by one to the predetermined station system. For example, the feeding and cutting mechanism of the packaging paper in the particle packaging machine, the lifting and positioning of the packaging container in the beverage filling production line, and the feeding system of some can sealing machines can also complete the orientation and feeding of the can lid.

(2) The measurement and delivery system of the packaged goods

The measurement and delivery system of the packaged goods is a system that measures, arranges, arranges, and delivers the packaged goods to the predetermined station, and some can also complete the stereotyping and segmentation of the packaged goods. Such as beer filling machine measurement and liquid supply system soap packaging machine soap finishing, arrangement and supply system.

(3) Main transmission system

The main transfer system is a system that transfers packaging materials and packaged items sequentially from one packaging station to the next packaging station, and the single-station packaging machine does not have a transfer system. Product packaging is often divided into multiple processes to complete, such as packaging materials and packaged items to be delivered, metering, filling, sealing, etc., to coordinate the completion of product packaging and output.

(4) Packaging actuator

The packaging actuator is the mechanism that directly completes the packaging operation, that is, the mechanism that completes the filling, sealing, wrapping, labeling, bundling and other operations. For example, the filling valve in the filling machine and the two sealing rollers in the can sealing machine are packaging actuators, and the sugar clipper hand and the knotter hand of the candy wrapping machine are also packaging actuators.

(5) Finished product output mechanism

The finished product output mechanism is a mechanism that unloads the packaged product from the packaging machine, arranges it in a directional manner and outputs it. The finished product output of some packaging machinery is completed by the main transmission mechanism or unloaded by the weight of the packaged product. Like a candy bar for a candy wrapper.

The power machine is the prime force of the work of packaging machinery, which is usually an electric motor in modern industrial production;

(6) Power engine and transmission system

The power machine is the prime motive force of the work of packaging machinery, usually the motor in modern industrial production, the transmission system refers to the power and movement of the power machine to the actuator and control system, so that it can achieve a fixed action device. It is composed of belt wheel, sprocket, gear, CAM, worm wheel, rod, etc., or mountain machine, electric, hydraulic, gas and other forms of transmission.

(7) Control system

The control system is composed of various automatic and manual devices. In the packaging machine, the output of power, the operation of the transmission mechanism, the action and cooperation of the loading actuator and the output of the packaging product are all controlled by the command of the mountain control system.

(8)The machine body

The fuselage is used to install, fix and support all the components of the machine to meet the requirements of their mutual movement and mutual position. Therefore, the fuselage must have sufficient strength, stiffness and stability.

1.1.2 Characteristics of packaging machinery Packaging machinery belongs to the category of light industry automatic machinery, in order to adapt to the packaging production of various products, there are many kinds. Through the analysis of the characteristics of a large number of packaging machinery, it can be seen that packaging machines are mostly automatic machinery. It not only has the north of general automatic machinery, but also has its own characteristics. The main features of packaging machinery are as follows.

Most packaging machinery has complex structure, fast movement speed and high precision. In order to meet the performance requirements, there are high requirements for the stiffness, dimensional accuracy and surface quality of the zero part. ② The work of packaging is generally small, so the motor power of packaging machinery is small. (3) Packaging machinery generally uses a stepless transmission device in order to flexibly adjust the packaging speed and adjust the production capacity of the packaging machine.

(4) Packaging machinery for food and drugs should be easy to clean, and the parts in contact with food and drugs should be made of stainless steel or chemically treated non-toxic materials.

(5) Packaging machinery is a special type of professional machinery, a wide variety of production is limited. In order to facilitate manufacturing and maintenance and reduce equipment investment, attention should be paid to standardization, versatility and versatility in the design of various packaging machines.

1.2 Classification and function of packaging machinery

1.2.1 Classification of packaging machinery

(1) According to the degree of automation of packaging machinery classification according to the degree of automation of packaging machinery is divided into automatic packaging machine and semi-automatic packaging machine. ① Automatic packaging machine automatically provides packaging materials and packaged items, and can automatically complete other packaging processes. The semi-automatic packaging machine provides packaging materials and packaged items manually, but can automatically complete other packaging processes

(2) according to the type of packaging products

According to the type of packaging products are divided into special packaging machine, multi-purpose packaging machine and general packaging machine. Special packaging machine Special packaging machine is specially used for packaging a certain product of the machine, ② multi-purpose packaging machine is by adjusting or replacing the relevant working parts, you can pack two or two kinds of products on the machine.

The general packaging machine is a machine suitable for packaging two or more different types of production within the specified range.

(3) Classified according to the function of the packaged product

China’s standard packaging machinery products with different main functions as the principle of division, according to the function of packaging machinery is divided into machinery, filling machinery, wrapping machinery, sealing machinery, labeling machinery, cleaning machinery, drying machinery, sterilization machinery, machinery, packaging machinery, multifunctional packaging machinery and other packaging operations of auxiliary packaging machinery 12 categories. As shown in table

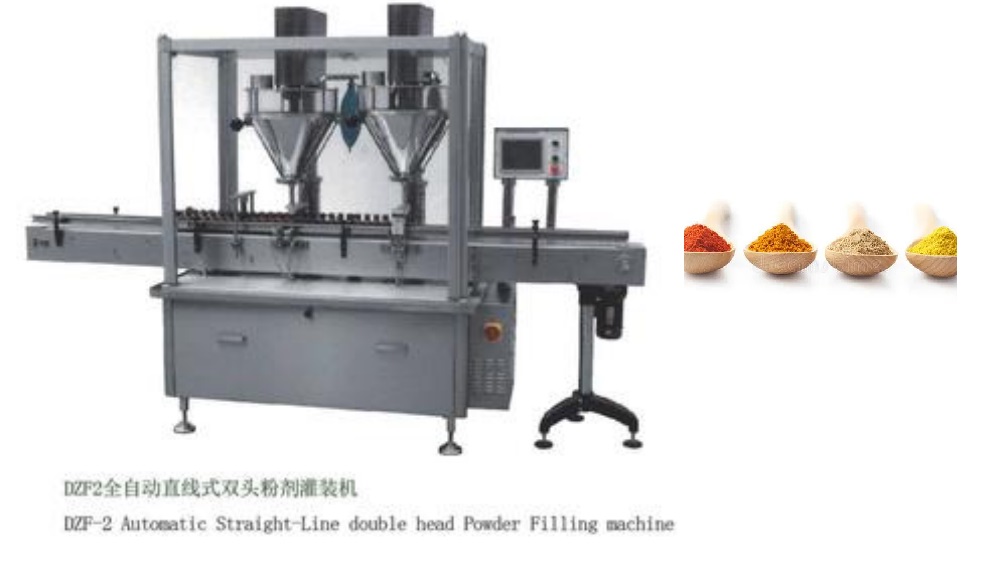

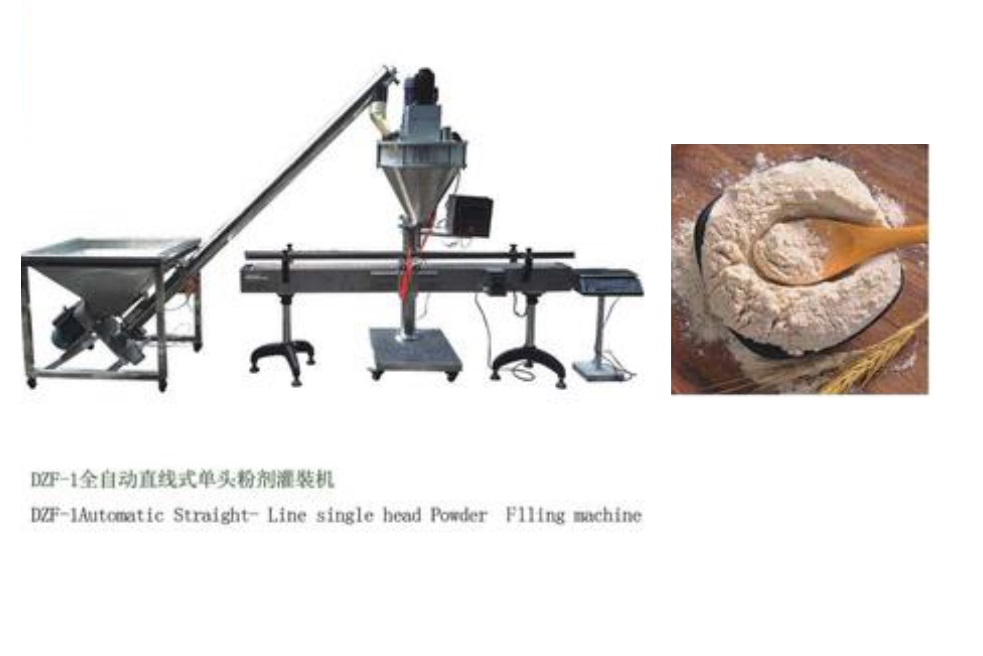

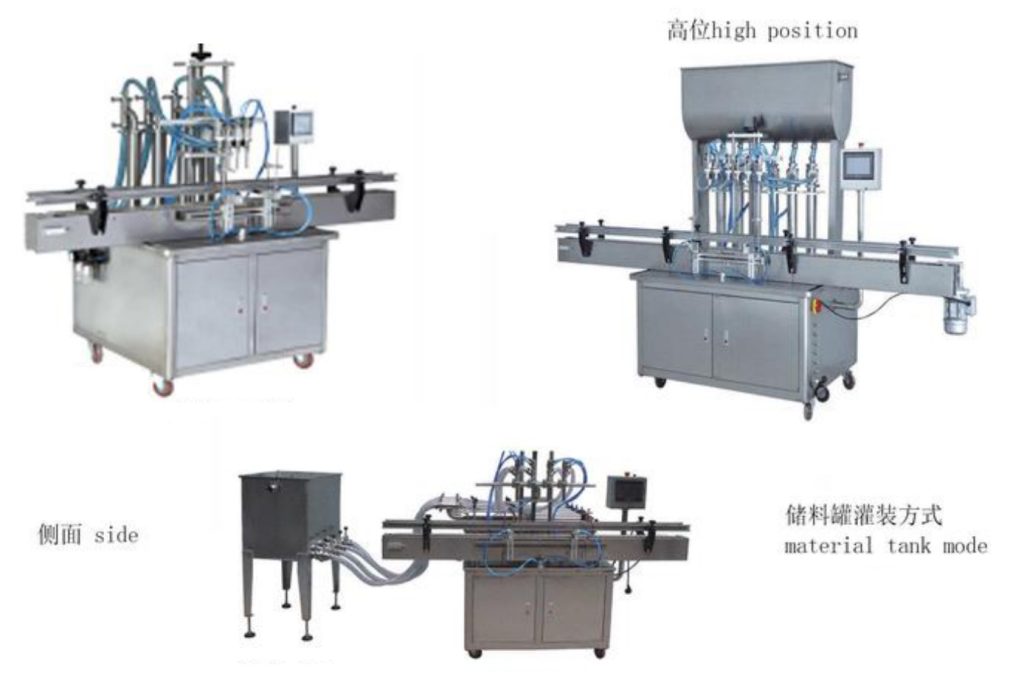

Filling machine, a machine that fills a predetermined amount of product into a packaging container

Category code: G

Category equipment name: Rotary filling machine

Product name: Bottle filling machine, which fills the product into the predetermined container

Main types:

Rotary filling machine

Straight line filling machine

Counting and filling machine

Pressure filling machine

Thermoforming machine

Weight filling machine

Positive displacement filling machine

Pressure liquid filling machine

Atmospheric pressure liquid filling machine

Other liquid filling machines

Sealer, a machine that seals the packaging container after it is filled with products

Category code: F

Category Equipment name: Pressure sealing machine

Product name: Pressure sealer, a machine that seals packaging containers by applying pressure

Main types:

Cap screwing machine

Cap rolling machine

Edge sealing machine

Bundling and sealing machine

Suture sealer

Ligation sealing machine

Half wrap sealer

Packers, machines that wrap products in whole or in part with loose packing materials

Category code: B

Category Equipment name: Full packing machine

Product name: Full wrap packing machine, with loose packaging material wrapped product machine

Main types:

labeler

Strapping and packing machine

Shrink packaging machine

Auxiliary packing machine

Auxiliary transport equipment

1.2.2 Role of packaging machinery

With the development of The Times and the progress of science and technology, packaging has gradually become a necessary condition for products to enter the circulation field, and packaging machinery is the main technical means to achieve product packaging, and its role in the product circulation field is becoming more and more important. Modern industrial production, such as food, medicine, daily necessities, chemical products, electronic products and other production, mainly includes three basic links, that is, raw material treatment, intermediate processing and product packaging. Product packaging is a very important link in industrial production, at the end of the production process and the beginning of the logistics process, both the end of production and the beginning of logistics, and packaging machinery plays a very important role in logistics. Packaging machinery is the fundamental guarantee for product packaging to achieve mechanization and automation, so packaging machinery plays a very important role in modern industrial production.

(1) Greatly improve production efficiency

Mechanical packing is much faster than manual packing. For example, the productivity of beer filling machine can be as high as 36,000 bottles/hour, which is unmatched by manual filling; The packaging of egg-shaped chocolate can be packed 20kg per person per shift by hand, and more than 250kg per person per shift can be packed by mechanical packaging; The candy packaging machine can pack hundreds or even thousands of pieces of sugar per minute, which is dozens of times the speed of manual packaging.

(2) Reduce labor intensity, improve working conditions manual packaging labor intensity, packaging large volume, heavy weight products, both physical exertion and unsafe;

Packaging light and small products, high frequency of action and single; Packaging liquid products, easy to cause the product splash; Packaging powdery products often causes dust to fly. The use of packaging machinery and equipment instead of manual packaging, not only can greatly improve the working conditions of workers and the environment, to avoid toxic products, irritating, radioactive products harm the health of workers, but also to liberate packaging workers from heavy labor. Such as manual packaging candy, a worker 8h to repeat the action more than 80,000 times; Such as artificial bags of fertilizer, dust flying pollution of the environment.

(3) Protect the environment, save raw materials, reduce product costs

Manual packaging of liquid products, easy to cause the product splash; Manual packaging powder products, easy to cause dust flying. This not only pollutes the environment, but also wastes raw materials. The use of mechanical packaging can prevent the loss of products, which not only protects the environment, but also saves

The raw materials.

(4) Ensure product hygiene, improve packaging quality Mechanical packaging is conducive to the hygiene of packaged products, improve product packaging quality, and enhance the competitiveness of market sales.

The hygiene requirements of some products are very strict, such as food, medicine, etc., the use of mechanical packaging can avoid direct contact with food and medicine, and because of the fast packaging speed, food and medicine stay in the air shorter time, reduce the chance of pollution, is conducive to product cleaning, to ensure the quality of product hygiene; In addition, due to the high measurement accuracy of the packaging machinery, it ensures the appearance of the product and the sealing is tight, improves the packaging quality of the product and can extend the shelf life of the product, and enhances the competitiveness of the market sales. Mechanical packaging is easy to achieve the normalization and standardization of packaging.

(5) Reduce packaging costs and save storage and transportation costs

For loose products, such as tobacco, silk, hemp and other products, the use of shrink-packaging machine for shrink-packaging, can be greatly woven.

Volume, reduce packaging costs, save storage capacity, reduce storage fees, conducive to transportation.

(6) Extend the shelf life and facilitate the circulation of products

The use of direct air, aseptic and other packaging machines for product packaging can extend the shelf life of food and beverages and make the flow range of products more extensive.

(7) Reduce the area of the packaging site and save infrastructure investment

The use of manual packaging, due to the packaging workers, the process is not compact, but the loading operation occupies a large area, the construction investment is more concentrated mechanical packaging products, products and packaging materials and packaging containers supply are more concentrated, the packaging arrangement is compact, make full use of the height of space, reduce the area required for manual packaging products, which can save infrastructure investment.

1.3 Packaging machinery model preparation method

The packaging machinery model is used to indicate the name, main parameters, improved design sequence and derived type code of the packaging machinery. The charter model consists of the main model and the auxiliary model. It is expressed in pinyin and Arabic numerals and is executed according to GB/T73112008 standard.

1.3.1 Preparation of the main model

The main model includes the classification name code of packaging machinery, the structural form code, and the optional project code. The classification name code is represented by the first pinyin letter of the representative Chinese name. In case of repeated letters, the sub-name code can be distinguished by the second pinyin letter, or the spelling combination of the representative Chinese name of the main function can be represented.

For products without a classification code name, the classification code name may be determined by itself; The structural form code and the selected project code are determined according to the product standard or the manufacturer itself.

1.3.2 Compilation of auxiliary models

The auxiliary model includes the main technical parameters of the product, the derived sequence code and the improved design sequence code

The main technical parameters are expressed in Arabic numerals and their limit values should be taken; If two or more groups of parameters need to be represented, separate them by slashes (/).

The main technical parameters commonly used in packaging machinery products are filling amount, packaging size, sealing size, filling valve number, production capacity, etc. Derivative sequence code with Roman numerals I, II, III… Indicates.

Improved design sequence code with English letters A, B, C…… To indicate; The first design of the product non-sequential code 1.3.3 packaging machinery model format

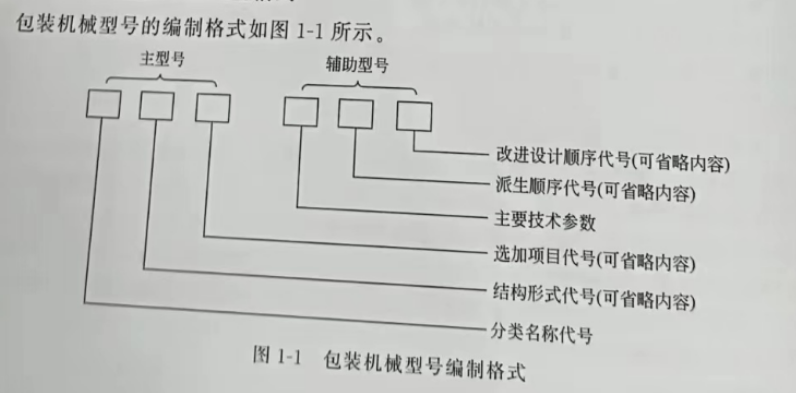

Figure 1-1 shows the format of packaging machinery models. Auxiliary type

Master type

Improved design sequence code (can omit content) Derived sequence code (can omit content) main technical parameters

Select project code (omit content)- Structural form code (omit content)

- Category name code

Figure 1-1 Model format of packaging machinery

1.4 Development trend of packaging machinery

With the continuous development of science and technology, various types of products have emerged, and new requirements have been put forward for packaging equipment and technology, and packaging machinery is playing an increasing role in the field of circulation. At present, the packaging machinery market competition is becoming increasingly fierce, the future packaging machinery will cooperate with the trend of industrial automation, promote the overall level of packaging equipment to improve, the development of multi-functional, high-efficiency and low-consumption packaging equipment, and packaging machinery technology is also developing towards the following trends.

(1) Mechatronics

Mechatronics is the development trend of packaging machinery in the future. A complete electromechanical integration system, generally including microcomputer sensor, power source, transmission system, actuator and other parts, it abandoned the conventional packaging machinery in the cumbersome and unreasonable part, and machinery, microcomputer, microelectronics, sensors and other disciplines of advanced technology integration, to packaging machinery in the design, manufacturing and control have brought profound changes, Fundamentally changed the status quo of packaging machinery.

(2) Precision of motion

Structural design and motion control are related to the performance of packaging machinery, which can be completed by high-precision controllers such as motors, encoders and digital control (NC) and dynamic load control (PLC), and moderately do product extension to develop packaging equipment for high-tech industries.

(3) Intelligent control At present, packaging machinery manufacturers generally use PLC power load controller, although PLC is very flexible, but still does not have the powerful function of microcomputer. In the future, packaging machinery must have multi-functional, simple adjustment and operation conditions, and intelligent instruments based on microcomputers will become a new trend in the development of packaging machinery controllers.

(4) Functional diversification and structural standardization of machinery

Industrial products have gradually become refined and diversified, in the environment changes, flexible and diversified packaging machine types can meet market demand; The design and manufacture of products should make full use of standardization and modularization to reduce the design and manufacturing workload in a short time

The packaging industry is a supporting industry, involving many areas of the national economy, especially the food industry and beverage industry, but also the conversion of new models. Rely on the technical progress of the packaging industry and supporting services. Therefore, we can not ignore the backward status quo of the domestic packaging machinery industry, and actively promote the packaging industry to embark on the road of rapid and healthy development of automation.

Reference

Translate from 包装机实用手册 李连进 主编 化学工业出版社

[1] Yin Zhangwei, Liu Quanxiang, Wang Wenjing. Introduction to Packaging. Beijing: Chemical Industry Press, 2003.

[2] Chen Manru. Introduction to Packaging Engineering (Bilingual). Beijing: Chemical Industry Press, 2005.

[3] Zhao H. Compilation of international Standards for packaging. Beijing: China Light Industry Press, 1994.

[4] Zhao Huai. Packaging machinery products. Beijing: China Light Industry Press, 2003.

[5] Packaging and Food Machinery Magazine. Packaging machinery product sample. 2nd Ed. Beijing: China Machine Press, 2008.

Zhou Binfei, Food and packaging machinery manufacturing technology. Chengdu: Sichuan Education Press, 1991.