Screw capping machine is also called capping machine, capping machine or locking capping machine, the main use is plastic bottles, glass bottles. Structure Feature: 1, the machine has reasonable and compact Structure, smooth running, flexible operation, convenient specification conversion and adjustment; 2, aluminum cover cover speed is adjustable; 3, automatic start and stop function; 4, the use of seven-station three-knife rolling cover principle, rolling aluminum cover without damage, rolling mouth firm, smooth, pass rate ≥99.5%

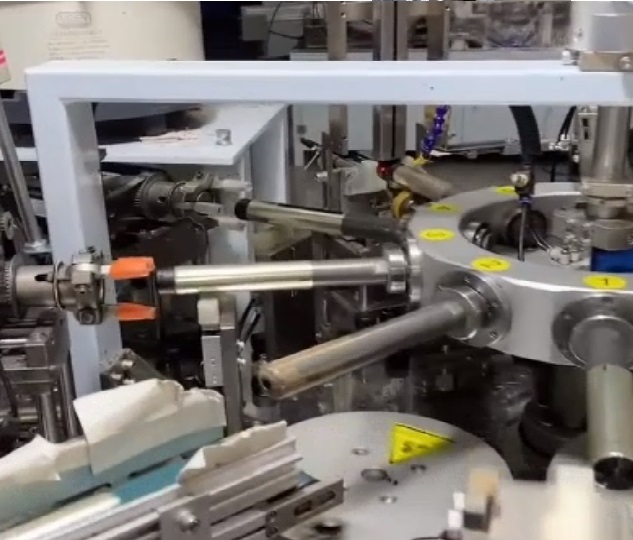

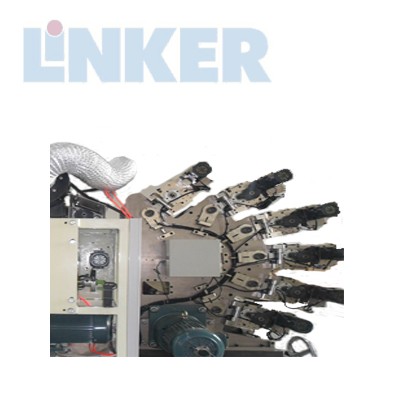

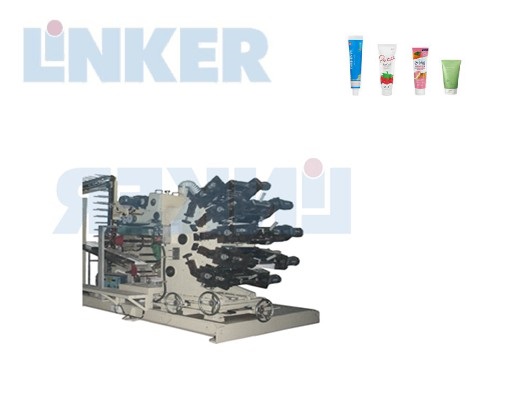

LHTK Soft Tube Drilling Sealing and Capping Machine

Automatic capping machine

Filling capping machine

Head Capping Machine

Glass bottle capping machine

LYLK Bottle Capping Machine

LYLK vacuum capping machine Glass Bottle

LYLK Plastic bottle capping machine

LYLK Filling and Capping Machine

Vacuum capping machine

Product Description:

Semi-automatic bench vacuum capping machine is a semi-automatic model (manual capping, manual entry and exit bottle). Using pneumatic drive capping, semi-automatic bench vacuum capping machine adopts precise control of actuator pressure to achieve torque control, non-friction torque limit makes the service life longer; Due to the reliable all-seal technology, the ideal vacuum degree can be achieved by configuring a low-power vacuum pump, and the vacuum degree can be set on demand. The semi-automatic bench vacuum capping machine is economical, widely applicable, easy to use, reliable and mobile, suitable for small production workshops, special specifications, and laboratory use.

Applicable products:

All glass screw cap with standard tinplate claw type screw cap products, such as condiment sauce, canned aquatic products, canned fruits, canned vegetables, bean products…… Let’s wait.

In particular, canned products requiring reliable vacuum packaging and high temperature and high pressure sterilization are required.

Main parameters:

Applicable bottle size range: bottle diameter 40~110 mm bottle height 55~180 mm.

Applicable cover type range: standard tinplate claw type screw open cover 38~82 mm

Capacity reference: 600 bottles per hour [Actual test]

True space: Adjustable up to -0.09Mpa

Dimensions: Width 350mm, height 790mm, depth 460mm. (Base size not included)

Host power supply: AC 220V

Host power consumption: less than 100 watts

Friendly tips: Semi-automatic desktop vacuum capping machine recommended configuration vacuum pump model: 2X-8A (two-stage rotary vane vacuum pump, pipe connection form, motor 1.1 kW, displacement 8 liters per second, limit vacuum -0.096Mpa)

Hand-held capping machine

Hand-held electric capping machine Technical parameter:

- Capping speed: about 25 bottles/min

- Net weight: 0.6kg/1.1kg

- Voltage: 220V 50/60Hz

- Clutch: Adjustable torque

- Screw cap range: 28-43mm

- Note: Small 20-33mm, medium 28-43mm, large 30-50mm optional (only one with the machine)

- Power supply size: 125×80×60mm

- Main machine: 60×60×300mm

Product introduction: 1. This type of capping machine is mainly used for unscrewing or tightening of various screw caps; 2, hand-held electric capping machine is easy to carry, can be easily used to tighten or loosen a variety of bottle caps.

3, its adjustable clutch can effectively avoid damage to the bottle cap and reduce the wear of the inner plug.

Hand-held pneumatic capping machine

Principle characteristics:

The hand-held pneumatic cap screw is widely used for unscrewing or tightening any screw cap, it has a wide range of screw cap, screw cap is not limited by the bottle height, shape size, weight, you can unscrew the cap and unscrew the cap, easy to operate, low failure rate and low price, is the best tool for screw cap tightening. It is especially suitable for use when the bottle is tall, large, heavy, or the bottle has a strange shape, or the cap has many specifications, and the cap head needs to be replaced frequently.

Table capping machine/Desktop electric capping machine:

Product Introduction:

This machine is suitable for screw pattern flat head plastic cap screw cap tightening, such as: lubricating oil barrels, mineral water bottles, medicine bottles, daily chemical supplies, beverage bottles, etc. Special specifications bottle caps can be customized suitable screw caps, we will do our best to meet the different needs of different customers.

Technical parameter

- Supply voltage: AC220V 50HZ

- Power rate: 50W

- Working efficiency: about 1200 bottles/hour

- Cap diameter: Φ10mm-Φ50mm

- Applicable bottle height: 40mm-200mm

- Net weight: 32Kg

- Main frame: 520×300×530m

Table type pneumatic capping machine

Product Introduction:

This machine is a new type of capping equipment produced by our company, and the accessories used are manufactured by domestic first-line manufacturers, which makes the equipment more stable performance, higher work efficiency and longer service life.

Technical parameter

- Power supply voltage: AC220V±10% 50HZ

- Power rate: 25W

- Cap diameter: Φ10 ~ Φ50MM

- Capping speed: 20 ~ 40 times/min

- Applicable bottle height: 40 ~ 200MM

- Air pressure: 1 ~ 5Kgf/cm2(air supply)

- Gas consumption: 0.03m3/ min

- Net weight: 30Kg

- Outer shape: 520×300×530mm

Main application: This type of capping machine is mainly used for unscrewing or tightening all kinds of screw caps.

Technical parameter

- Screw cap range: 5-30mm30-90mm

- Capping speed: about 30 bottles/min

- Net weight: 0.6kg/1.1kg

- Air pressure: greater than 4.5kg/cm2, less than 6.2kg/cm2

- Air consumption: 0.08m3/min

- Quick connector: 1/4 inch

- Clutch: Adjustable

Suitable for different materials and different specifications of bottle cap, screw cap, screw cap, anti-theft cap, child-proof cap, pressure cap, etc. Equipped with constant torque screw head, the pressure can be easily adjusted. Compact structure, reasonable, can be easily linked with other equipment line.

Glass Bottle and Plastic bottle capping machine is Suitable for capping Various of Bottles: Glass Bottle, Plastic Bottle,

Plastic Bottle: mineral water bottle, beverage bottle, medicine bottle, lotion bottle, washing lotion, Laundry detergent hand sanitizer, Oil bottle, medicine bottle, eye medicine bottle, Soy sauce, Toilet cleaner bottle, disinfectant bottle, hand sanitizer bottle, laundry detergent bottle, tomato sauce bottle,

Glass Bottle: cosmetic bottle, lotion bottle, honey bottle, sweet bottle, wine bottle, whiskey bottle, water bottle, perfume bottle, spice glass bottle, sauce glass bottle, and so on.

Bottle have various types:

- Small mouth bottle. It is a glass bottle with an inner diameter of less than 20mm, which is mostly used for packaging liquid materials, such as soda and beer.

- Big mouth bottle. The inner diameter of the bottle mouth is between 20-30mm glass bottles, the body is thicker and shorter, such as milk bottles.

- Wide mouth bottle. Also known as canning bottle, the inner diameter of the bottle mouth is greater than 30mm, its neck and shoulder are shorter, the bottle shoulder is relatively flat, and it is mostly can-shaped or cup-shaped. Due to the large mouth of the bottle, the loading and discharging are easier, and it is mostly used for packaging canned food and viscous materials.

According to the bottle geometry classification

- Round bottle. The cross-section of the bottle is round, is the most widely used bottle type, high strength.

- Square bottles. The section of the bottle is square, and the strength of this bottle is lower than that of the round bottle, and it is difficult to manufacture, so it is used less.

- Curved bottles. Although the cross-section is round, but in the height direction is a curve, there are two kinds of concave and convex, such as vase type, gourd type, etc., novel form, very popular with users.

- Oval bottle. The section is elliptical, although the capacity is small, but the shape is unique, and the user also likes it.

CAPS suitable for plastic caps, metal caps, aluminum caps, head cap, ropp caps, lock cap, gland cap, screw caps, and so on.

- Production capacity: 7ml 150 bottles /min

- 10ml~12ml 120 bottles /min

- Power rate: 1.5KW 380V 50Hz

- Overall dimensions: (L×W×H) 1100×620×1750 mm

- Weight: about 500Kg

Working Principle and Feature:

The hand-held electric capping machine is easy to carry around and can be easily used to tighten or loosen various bottle caps. Its adjustable clutch effectively avoids damage to the cap and reduces wear on the inner plug. Once the cap is tightened, the holder automatically stops rotating, indicating that you can proceed to the next cap. If you also choose a stand, you can turn the cap screw up in a light and clean way. This series of machines can effectively reduce the labor intensity and ensure the quality of the capping.

The whole machine includes: main machine, aluminum screw cap card head and buffer inner plug.

Automatic capping machine

Main applications: Suitable for all kinds of cosmetics, medicine, veterinary drugs, pesticides, lubricating oil industry bottle cap machine equipment.

Principle and features: Automatic capping machine is mainly suitable for different material specifications and different specifications of the cap, rolling (rolling) cap. Suitable for screw cover, anti-theft cover, child-proof cover, pressing cover, etc. Equipped with constant torque screw head, the pressure can be easily adjusted. Compact structure, reasonable, can be easily linked with other equipment line, dust cover optional. Machine advantages: linear design, assembly line convenient and beautiful.

The speed of the main machine is imported frequency converter, which can be stepless speed regulation.

The use of strong electromagnetic left cap torque completely solves the problem of the traditional mechanical friction plate being tight and loose when capping.

- Connect the power cord of the capping machine to the power box;

2, connect the power supply, the power box indicator light; - Put the cap on the bottle with your left hand.

- Hold the bottle with the left hand;

5, hold the capping machine with the right hand, the rotating head is vertically aligned with the bottle cap; - Press the starting switch of the capping machine with the right index finger, and press down at the same time until the clutch of the capping machine is automatically clutch, issuing a “dada dada…” According to the tightness of the screw cap, the screw cap head need not be pressed too tightly;

7, adjusting the tightness of the bottle cap can be achieved by adjusting the torque adjustment nut between the rotary head and the rotary machine, the greater the torque, the tighter the bottle cap, the smaller the torque of the loose nut, the more the bottle cap

Operating manual

1, feed half adjustment.

A. Adjust the bottle board a on the feeding half upward to shorten the feeding stroke; Downward adjustment to accommodate longer bottle feeding travel.

b, the left and right adjustment of the positioning bottle position so that when the movable teeth are running, the right bottle position so that the bottle is smoothly fed into the positioning teeth.

c, adjust the bottle board B to make the width of the bottle entrance ≈22 mm.

2, the perfusion component adjustment, the role of the perfusion component is to make the liquid through the perfusion device, check valve, needle in a timely manner to each easy to pull bottle, so the needle into the bottle must be appropriate, and the filling time should be appropriate.

a, adjust the side CAM A turn or reverse so that the needle is inserted into the mouth of the empty bottle just into the tooth position. And lift the needle before leaving the tooth position.

b, infusion time adjustment: turn CAM B clockwise or reverse the adjustable needle into the bottle mouth immediately after the start of filling, before the needle leaves the bottle mouth stop filling.

c, liquid volume adjustment: loosen the nut 1 adjust the ejector rod in the D direction to increase the liquid volume; Adjust the liquid amount in the direction of C to reduce, while adjusting nut 2 to reduce the liquid amount in the direction of F, adjust the liquid amount in the direction of E to increase the liquid amount, pay attention to the limit position of the filling device when adjusting, so as not to damage the filling device, generally the bottom of the filling device to the drug PFS not less than 15 mm, the longer the perfusion time the better.

- Working principle and adjustment of automatic stop liquid filling device.

When the moving tooth plate moves the bottle to the position of the stop tooth of the filling liquid, the convex surface of the CAM 7 and the swinging plate 6 leave, the swinging plate 6 is pulled by the tension spring 4, and the swinging plate 6 drives the bottle pressing bolt 2 downward until it contacts the bottle 3. At this time, the steel wire rolling head 5 swinging plate 6 should be adjusted to contact and adjust the adjusting screw 8 so that the top rod bolt 1 extends about 4 mm. There is an empty bottle in this stop position, and the bottle pressing bolt 2 and the shaking plate 6 continue to move down due to the action of the tension spring 4, so that the steel wire mangle 5 pulls the steel wire and the ejector bolt 1 is removed from the ejector rod 9, so the drug filling device cannot be driven to work and the infusion liquid is automatically stopped. - Discharge precautions

Because the machine is easy to pull bottle filling and locking equipment, the discharge is sealed. In order to prevent the bottle from tipping over after the filling and locking, it is necessary to put several empty bottles on the discharge hopper before the first bottle discharging to keep the bottle after the filling and locking smoothly transported to the discharge hopper and sent to the next process with the bottle filling bucket.

5, this locking device is the digestion of foreign advanced technology, according to the domestic oral liquid production situation specially designed for the existing specifications of easy to pull bottles, so the easy to pull bottle geometric size and error have certain requirements, if there are special requirements or other specifications please contact our technical department. - Adjustment of lock device

a, gland time adjustment: adjust the CAM 3 rotation Angle when the infusion bottle enters the lock position, the lock shaft has been moved and leaves the bottle cap before moving the teeth close to the bottle.

b, gland pressure adjustment: the size of the gland pressure is directly related to the quality of the lock, the pressure is too large to make the easy-to-pull bottle broken, the pressure is too small will affect the sealing performance, so the nut should be adjusted according to the actual average height of the easy-to-pull bottle, so that the pressure is adjusted to the best.

c, blade action time adjustment: blade 2 should be close to the bottleneck before the end of the gland, otherwise some short bottles can not reach the locking effect, loosen the nut 4 when adjusting, adjust the shaft 5, up and down can make blade 2 action time sooner or later. Note that the elasticity of the adjustment spring 7 should be greater than that of the spring 8 to keep the bottleneck consistent.

d, adjusting the lock: all departments must pay attention to the nut lock after adjustment, the initial valve test with easy pull bottle, must take its average height, irregular easy pull bottle can not enter the lock, so as to avoid damage to the parts. - Adjustment of vibrator

The automatic cap drop adopts the principle of electromagnetic oscillation to drop the cap along the track to the appropriate position.

A. The vibrator is packaged separately before leaving the factory, and the lower track mouth must be aligned with the moving track of the easy drawing bottle when it is installed.

b, the adjustment of the magnet gap: loosen the screw 1, open the outer cover, adjust the nut 2, so that the magnet gap is 0.6-0.8, and the lowest vibration sound of the bottle cap line speed is appropriate.

- After the machine is unpacked, first check whether the random technical information is complete and whether the machine is damaged during transportation in order to solve it in time.

- Install and adjust the feed assembly and discharge assembly according to the appearance diagram in this manual.

- Add new lubricating oil to each lubrication point.

- Rotate the machine with the swing handle to check whether the machine is running in the correct direction (counterclockwise direction facing the motor spindle), and the machine must be grounded.

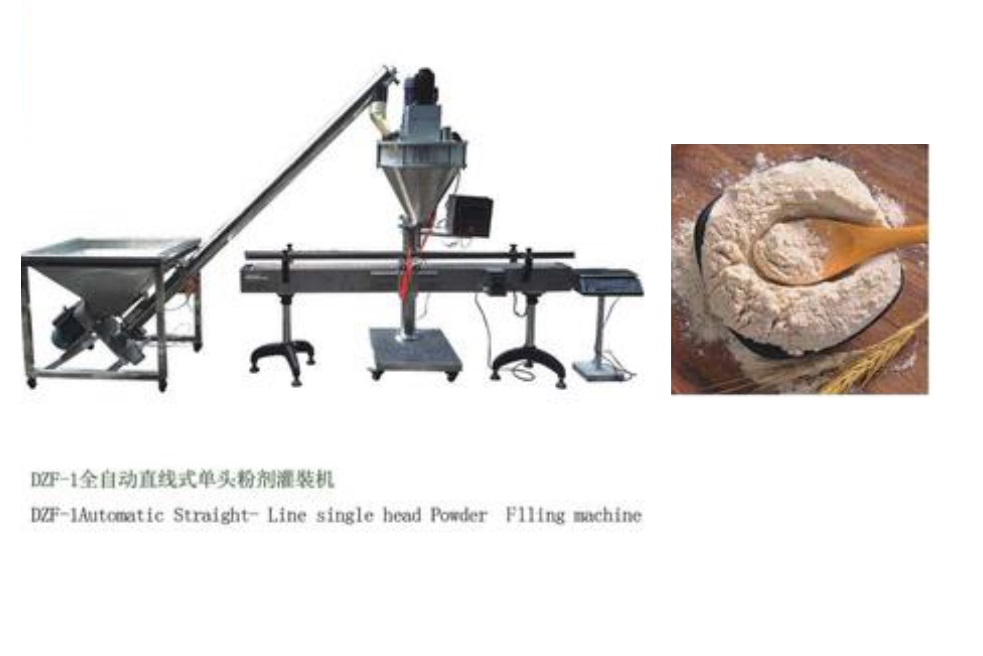

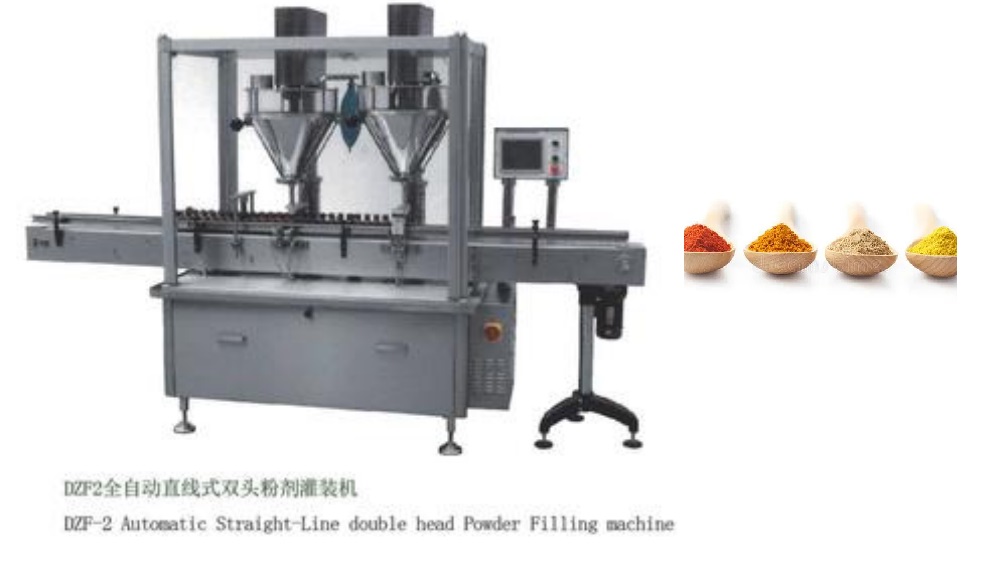

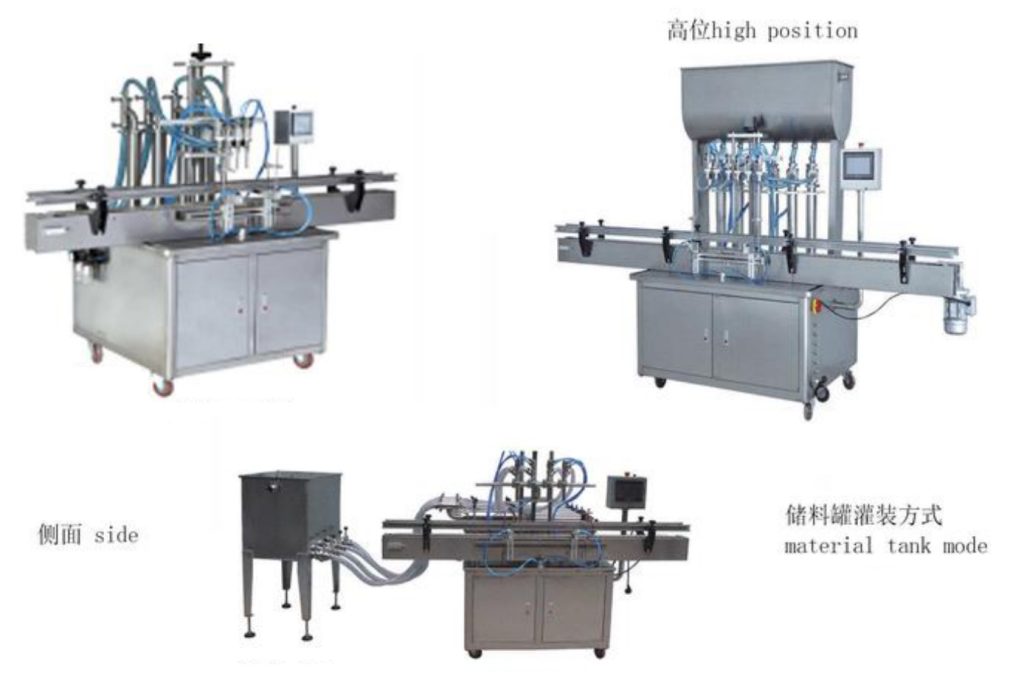

Powder Filling Machine:

Powder, Liquid, Paste, Granule filling machine Customization:

We have various types of Granule filling machine for sale, and we do customization according to customer’s speed and capacity. We can also design and produce the whole production line including the grinder , Blending machine, drying machine, conveyor, feeder, vibrating Screen, Packing Machine… Please contact us quotation, parameters and price.

Customize Plastic Bottle Capping Machine According to your Capacity:

We can customize Granule filling machine connect with your production line (the dimension and width of feeder).

Customize Glass Bottle Capping Machine According to your Capacity:

Videos of Filling Machine :

We have many model of Powder, Liquid, granule, paste Filling and Capping Machine , here show some examples:

Production Line Customization Solution:

We can customize whole automatic production line according to customer special request. According to your special material, capacity requirement and motor and electric cabinet certification requirement, we can customize semi-auto or fully automatic production line for our customer. Please contact us for detail proposal and quotation.

Air Below Washing Machine + Sterilize Machine + Filling Machine + Metal Detector + Check Weight + Capping Machine Sealing Machine + Labeling Machine + Label Shrink Film

Drying Machine + Grinding Machine + Sifter Machine + Mixing Machine + Packing Machine:

Factory Information

Factory Information

| Business Type: | Manufacturer/Factory | Main Products: | Mill, grinder, granulator, mixer, Crushing Equipment |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000 Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

Certifications:

Machine Packing:

Small machine packed with export fumigation-free wooden cases, goes with bulk shipment or in container.

Installation:

- The machine is installed according to the instructions after unpacking, and the compressed air source is connected. If the air source pressure is 0.6MPa, the valve should be installed first in the compressed air main pipeline.

2, open the right door to turn out the oil mist oil label to add clean special oil, or sewing machine oil, note: when the fuel can not be with air pressure, the oil amount of about 8 minutes full is appropriate.

3, the intake air source check whether the sealing surface is leaking, adjust the air pressure to 0.3~0.4MPa to adjust the oil intake, generally spray a drop of oil after several times, regularly check the oil injection.

4, filling volume adjustment: first rotate the filling volume adjustment hand wheel, observe the indicator window scale, so as to achieve the required amount of filling, at the same time adjust the suction, discharge speed to achieve satisfactory filling effect, the dosage standard measure the filling amount, and finally correct the filling amount.

Warranty of Machine:

We provide one year warranty for all our machine, but not including the man-made damage. We can provide free spare parts if damage in one year in normal operation. 24hours stand by to solve urgent problems. 3 days of spare parts provide by express. Please specially notice for the motor connection. it should be connect in right way to prevent the motor burnt, take special notice of running machine safely. Machine need to be clean and maintained frequently.

Maintenance of machine:

Servo filling machine as an important equipment in the automated production line, its maintenance is very important to ensure production efficiency and product quality. The following is an overview of the general servo filling machine maintenance procedures:

Routine maintenance

Cleaning and inspection:

Before and after each shift, clean the external surface of the servo filling machine, especially the working area and transmission components.

Check for debris and foreign objects around the machine and keep the working environment clean and tidy.

Lubrication:

According to the requirements of the equipment manual, regularly fill the lubricating parts of the servo filling machine with appropriate lubricating oil or grease.

Be careful not to over-lubricate or leak to avoid contaminating the product.

Check the transmission components:

Regularly check the tension and wear of the drive belt, chain and gear, and adjust or replace damaged parts in time.

Cleaning and replacing filters:

Regularly clean or replace the servo filling machine air filter, hydraulic filter, etc., to ensure the smooth system and reduce the failure rate.

Scheduled maintenance

Electrical parts inspection:

After powering off the device, check that electrical connections, switches, control panels, and sensors are secure and working properly.

Check cable and wiring wear regularly to avoid short circuit or open circuit.

Pneumatic system maintenance:

Check the working condition of pneumatic components, cylinders and solenoid valves to ensure that the gas path is smooth and there is no leakage.

Servo system calibration:

According to the requirements of the equipment manual, the servo system is calibrated and adjusted regularly to ensure the running accuracy and stability.

Spare parts replacement:

According to the service life of the equipment and the depletion of spare parts, timely replacement of vulnerable parts and key components, such as seals, valves, etc.

Performance test:

Regularly carry out the performance test and function test of the servo filling machine, confirm whether the functions are normal, adjust the parameters and control logic.

Emergency handling

Troubleshooting:

If the device is faulty or abnormal, shut it down immediately and handle it according to the troubleshooting guide in the device manual.

Maintenance records:

Record the specific content, time and operator of each maintenance, and establish maintenance files to facilitate traceability and analysis of equipment operating conditions.

By strictly implementing the above maintenance procedures, the reliability and stability of the servo filling machine can be improved, the service life of the equipment can be extended, and the continuous operation of the production line and the stability of product quality can be ensured.

FAQ

We are factory located in Shanghai China, welcome to visit our team.

1. Normally 30% deposite payment, balance 70% before shipment.

2. We can provide L/C for special country.

1. For some simple machine, we will install before shipment, no need to do complicate install on customer side.

2. For complicate machine, our engineer is available for going customer side, but the visa fee, round flight ticket, hotel and food are undertaken by customer. Besides, engineer compensation 100USD/Day. Engineer can provide installation services, and also available to teach your operator how to use it.

1. Talk with our sales about your product size and applications, capacity you need per minute, For example 50 pcs/minute. we will provide the right mode for you.

2. Place Order and do the first Payment.

3. Produce and send video for your green light.

4. You do the final Payment

5. Arrange shipment

6. Receive goods.