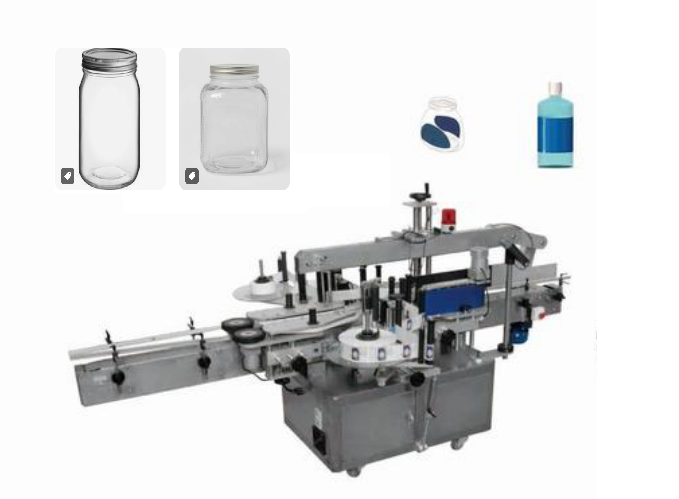

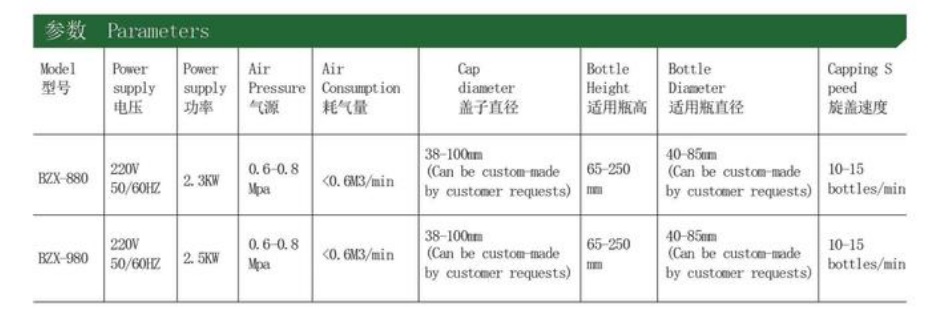

- Bottle Height : 60-250mm;

- Bottle Diameter: 40-85mm;

- Capping Speed: 10-15bottles/min

- Output: 5-15pcs/minute;

- Price: 2800USD.

Product Information

Suitable for Glass Bottle.

Glass Bottle and Plastic bottle capping machine is Suitable for capping Various of Bottles: Glass Bottle, Plastic Bottle,

Plastic Bottle: mineral water bottle, beverage bottle, medicine bottle, lotion bottle, washing lotion, Laundry detergent hand sanitizer, Oil bottle, medicine bottle, eye medicine bottle, Soy sauce, Toilet cleaner bottle, disinfectant bottle, hand sanitizer bottle, laundry detergent bottle, tomato sauce bottle,

Glass Bottle: cosmetic bottle, lotion bottle, honey bottle, sweet bottle, wine bottle, whiskey bottle, water bottle, perfume bottle, spice glass bottle, sauce glass bottle, and so on.

Bottle have various types:

- Small mouth bottle. It is a glass bottle with an inner diameter of less than 20mm, which is mostly used for packaging liquid materials, such as soda and beer.

- Big mouth bottle. The inner diameter of the bottle mouth is between 20-30mm glass bottles, the body is thicker and shorter, such as milk bottles.

- Wide mouth bottle. Also known as canning bottle, the inner diameter of the bottle mouth is greater than 30mm, its neck and shoulder are shorter, the bottle shoulder is relatively flat, and it is mostly can-shaped or cup-shaped. Due to the large mouth of the bottle, the loading and discharging are easier, and it is mostly used for packaging canned food and viscous materials.

According to the bottle geometry classification

- Round bottle. The cross-section of the bottle is round, is the most widely used bottle type, high strength.

- Square bottles. The section of the bottle is square, and the strength of this bottle is lower than that of the round bottle, and it is difficult to manufacture, so it is used less.

- Curved bottles. Although the cross-section is round, but in the height direction is a curve, there are two kinds of concave and convex, such as vase type, gourd type, etc., novel form, very popular with users.

- Oval bottle. The section is elliptical, although the capacity is small, but the shape is unique, and the user also likes it.

CAPS suitable for plastic caps, metal caps, aluminum caps, head cap, ropp caps, lock cap, gland cap, screw caps, and so on.

What is vacuum capping machine:

Vacuum capping machine generally refers to the equipment used for the vacuum capping packaging of glass tinplate. The glass bottle mouth is with spiral, the lid material is usually tinplate, with the corresponding bottle mouth thread number equal to the buckle, according to different bottle diameter standards for three, four, six buckle caps, respectively supporting the corresponding number of screw glass bottles. As for why the vacuum capping machine is used for this glass bottle tinplate screw cap packaging, it is required that the vacuum in the packaging container can be maintained. The container must be rigid enough, otherwise it will deflate, and the lid must have enough sealant and can be firmly fastened or screwed with the bottle in order to maintain the vacuum in the bottle for a long time. In addition to some special rare forms that can meet these two premises, this is the only one commonly used in the range of rigid can packaging.

Model:

The models of the vacuum capping machine can be divided into three types: steam jet type, semi-sealed vacuum type and fully sealed vacuum type.

Steam jet type strictly speaking, there is no vacuum chamber, but the steam tunnel is equivalent to the exhaust box exhaust, and the cover is closed and rolled in the short exhaust process

Semi-sealed vacuum type uses the sealing ring at the top of the machine to press down on the shoulder of the bottle to form a vacuum chamber, because a part of the vacuum chamber is the bottle itself, so it is called a semi-sealed vacuum chamber, refer to the “screw cover vacuum sealing machine (JB/T10642-2006)”.

The fully sealed vacuum type is provided with a structure that can completely form a vacuum chamber on the machine, and the bottle is completely placed in the vacuum chamber to realize the vacuum with a screw cap.

Feature:

Each of these three forms has its own characteristics:

First of all, steam jet has the advantage of high yield, but the disadvantage is that it needs to inject a large amount of steam into the steam tunnel, and the actual steam utilization rate is very low, the leaking steam may affect the workshop environment, and the steam entering the bottle will affect the quality of some products after liquefaction; The two-in-line type generally adopts the structure of belt spinning, which cannot ensure that the force of each bottle and bottle cap is consistent, which will cause fracturing damage to the bottle body and damage to the cap buckle or not rotating in place, and the vacuum degree that can be achieved is equivalent to the effect of the exhaust box. At present, it is mainly used in fruit canned production line.

Because the motion amplitude of forming the vacuum chamber is relatively small, the void gap of the vacuum chamber is less, so the speed of the vacuum capping machine in the form of the semi-sealed vacuum chamber is higher than that of the full seal, but for bottles with errors in the shape of the bottle shoulder, small shoulders or bottles with a diameter larger than the bottle, and non-round bottles, This way of borrowing part of the bottle to form a vacuum chamber can not help. In addition, the semi-sealed model cannot be automatically capped, and vacuuming in the semi-capped state requires a larger vacuum device and cannot guarantee that every bottle can be vacuumed.

How to Operate:

- Connect the capping machine power cord to the power box, connect the power supply, the power box indicator light;

- Put the cap on the bottle with your left hand;

- Hold the bottle with the left hand;

- hold the capping machine with the right hand, the rotating head is vertically aligned with the bottle cap;

- the right index finger press the starting switch of the capping machine, while pressing down until the capping machine clutch

- Moving clutch, issuing “dada dada…” According to the tightness of the screw cap, the screw cap head need not be pressed too tightly;

- adjusting the tightness of the bottle cap can be achieved by adjusting the torque adjustment nut between the rotary head and the rotary machine, the greater the torque, the tighter the bottle cap, the smaller the torque of the loose nut, the looser the bottle cap.

Development Trend:

With the rapid development of science and technology and the continuous acceleration of the industrialization process, the rapid development of the vacuum machine industry and application space make it become one of the essential industries of modern life, and occupy an important position in the development of the economy, vacuum machine as one of the unique processes of commodity packaging, Its vacuum packaging form and the role of protecting goods make it in the market to enhance the Sunday, in order to attract more consumers’ favor, the vacuum machine to the development trend of the market trend. In order to open up a broader development space and market for the industry, domestic businesses engaged in vacuum machines can continue to work hard, actively introduce advanced technology and ideas, and vigorously explore the potential business opportunities in the domestic market of vacuum machines.

Due to the continuous improvement of people’s lives, people’s requirements for goods are getting higher and higher, which is reflected in the higher and higher requirements for the packaging of goods, and the capping machine industry has a close relationship with the packaging of goods, as the capping process of commodity packaging, the vacuum capping machine has outstanding advantages and quality control. And in the process of commodity packaging has a good performance. Pike dragon company is the largest company specializing in vacuum capping machine business, its equipment and vacuum packaging machine, vacuum capping machine outstanding technical advantages and market position is the most prominent, in order to achieve the winner’s position in the market competition, Pike dragon company in the development can be described as continuous efforts.

For the development of the industry, suitable for market demand is the fundamental guarantee for the development of the industry and the source of strength, which is also true for the development of the vacuum cap machine industry, only to adapt to the needs of the market, only in the highly competitive market to be reinvented in order to compete with competitors in the same industry.

The development of vacuum capping machine is the result of vacuum packaging technology, so in the face of the development requirements of the new era, where should the development direction of vacuum packaging machine go? At this stage, the international development trend of vacuum packaging machines is mainly reflected in the following aspects.

First, the application of new technology is essential: in packaging technology, a large number of inflatable packaging replaces vacuum packaging, and closely combines the research of inflatable ingredients, packaging materials and inflatable packaging machines; In terms of sealing, heat pipe and cold sealing technology are used; The device to improve the predecessor is directly installed on the vacuum capping machine, such as the installation of computer-controlled high-precision coarse particles combined scale; In the rotary or vacuum capping machine, the circular arc face CAM indexing machine is used to improve the high speed of the predecessor. The application of all these new technologies has made the vacuum capping machine develop towards a more efficient and intelligent trend.

Second, the automation is gradually emerging: the automation of the vacuum capping machine not only improves the production efficiency, but also avoids the complexity and trouble of manual manipulation, and ensures the safety and health of the products in the production process. At present, the level of automation of vacuum capping machine in the international market has become an important measure of equipment, although automation has not been widely used in China, but a series of automatic vacuum capping machine launched by Xiangbo company has won praise and recognition in the market, automatic vacuum capping machine has slowly revealed its edge.

Three, to achieve single multi-function: to achieve multi-function on a single machine, can facilitate the vacuum capping machine to expand the scope of use in various industries. The multi-function of the single machine is completed by modular design, through the transformation and combination of different functional modules, the production of different packaging materials, packaging mouth, packaging requirements of the vacuum capping machine. The vacuum capping machine produced by Xiangbo Packaging machinery can set bag making, weighing, filling, vacuuming, sealing and other functions in one, convenient and fast.

Parameter

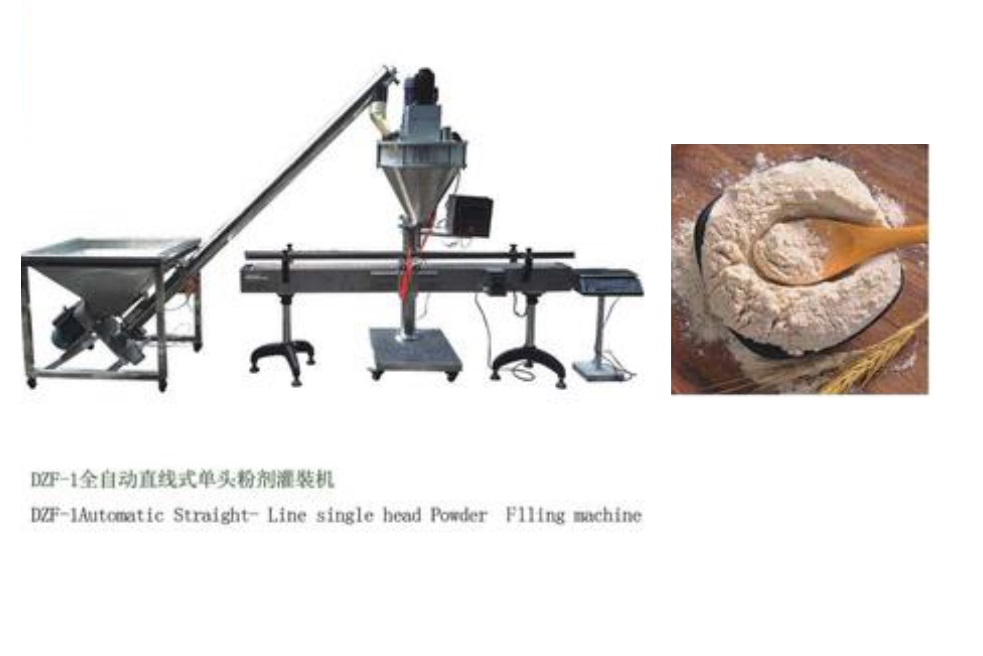

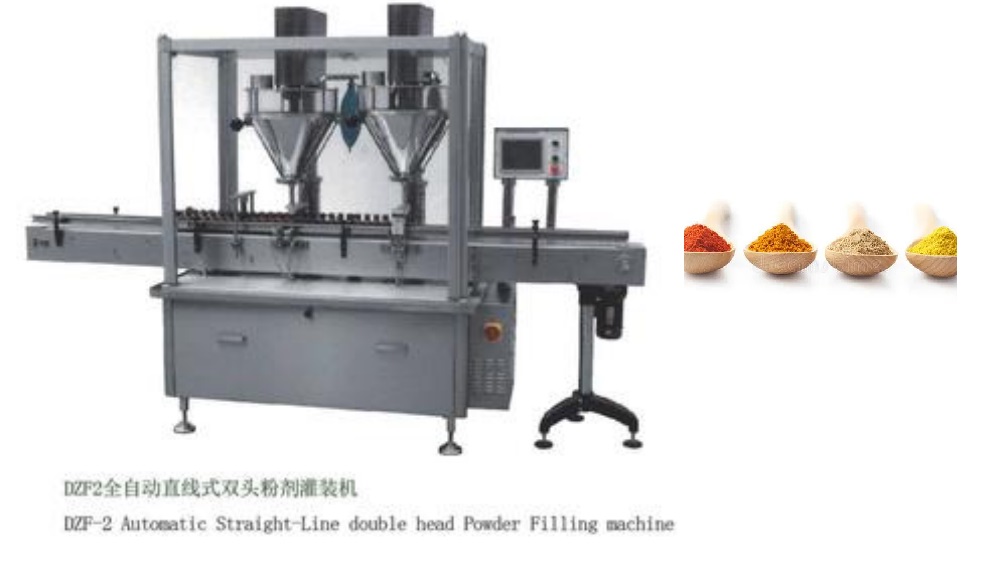

Powder Filling Machine:

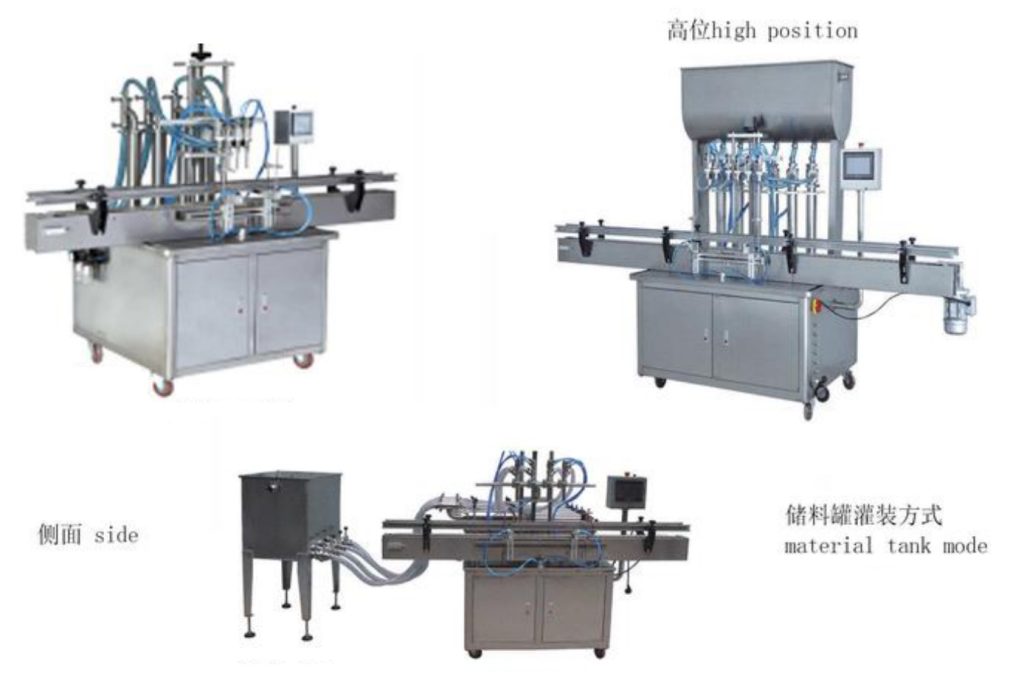

Powder, Liquid, Paste, Granule filling machine Customization:

We have various types of Granule filling machine for sale, and we do customization according to customer’s speed and capacity. We can also design and produce the whole production line including the grinder , Blending machine, drying machine, conveyor, feeder, vibrating Screen, Packing Machine… Please contact us quotation, parameters and price.

LYLK Pneumatic Filling Machine

LYLK Filling and Stoppering machine

LYLK Filling and Capping Machine

LYLK Servo Filling Machine

LYLK Automatic filling and sealing machine

Customize Plastic Bottle Capping Machine According to your Capacity:

We can customize Granule filling machine connect with your production line (the dimension and width of feeder).

Customize Glass Bottle Capping Machine According to your Capacity:

Videos of Filling Machine :

We have many model of Powder, Liquid, granule, paste Filling and Capping Machine , here show some examples:

Production Line Customization Solution:

We can customize whole automatic production line according to customer special request. According to your special material, capacity requirement and motor and electric cabinet certification requirement, we can customize semi-auto or fully automatic production line for our customer. Please contact us for detail proposal and quotation.

Air Below Washing Machine + Sterilize Machine + Filling Machine + Metal Detector + Check Weight + Capping Machine Sealing Machine + Labeling Machine + Label Shrink Film

Drying Machine + Grinding Machine + Sifter Machine + Mixing Machine + Packing Machine:

Factory Information

Factory Information

| Business Type: | Manufacturer/Factory | Main Products: | Mill, grinder, granulator, mixer, Crushing Equipment |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000 Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

Certifications:

Machine Packing:

Small machine packed with export fumigation-free wooden cases, goes with bulk shipment or in container.

Installation:

- The machine is installed according to the instructions after unpacking, and the compressed air source is connected. If the air source pressure is 0.6MPa, the valve should be installed first in the compressed air main pipeline.

2, open the right door to turn out the oil mist oil label to add clean special oil, or sewing machine oil, note: when the fuel can not be with air pressure, the oil amount of about 8 minutes full is appropriate.

3, the intake air source check whether the sealing surface is leaking, adjust the air pressure to 0.3~0.4MPa to adjust the oil intake, generally spray a drop of oil after several times, regularly check the oil injection.

4, filling volume adjustment: first rotate the filling volume adjustment hand wheel, observe the indicator window scale, so as to achieve the required amount of filling, at the same time adjust the suction, discharge speed to achieve satisfactory filling effect, the dosage standard measure the filling amount, and finally correct the filling amount.

Warranty of Machine:

We provide one year warranty for all our machine, but not including the man-made damage. We can provide free spare parts if damage in one year in normal operation. 24hours stand by to solve urgent problems. 3 days of spare parts provide by express. Please specially notice for the motor connection. it should be connect in right way to prevent the motor burnt, take special notice of running machine safely. Machine need to be clean and maintained frequently.

Maintenance of machine:

Servo filling machine as an important equipment in the automated production line, its maintenance is very important to ensure production efficiency and product quality. The following is an overview of the general servo filling machine maintenance procedures:

Routine maintenance

Cleaning and inspection:

Before and after each shift, clean the external surface of the servo filling machine, especially the working area and transmission components.

Check for debris and foreign objects around the machine and keep the working environment clean and tidy.

Lubrication:

According to the requirements of the equipment manual, regularly fill the lubricating parts of the servo filling machine with appropriate lubricating oil or grease.

Be careful not to over-lubricate or leak to avoid contaminating the product.

Check the transmission components:

Regularly check the tension and wear of the drive belt, chain and gear, and adjust or replace damaged parts in time.

Cleaning and replacing filters:

Regularly clean or replace the servo filling machine air filter, hydraulic filter, etc., to ensure the smooth system and reduce the failure rate.

Scheduled maintenance

Electrical parts inspection:

After powering off the device, check that electrical connections, switches, control panels, and sensors are secure and working properly.

Check cable and wiring wear regularly to avoid short circuit or open circuit.

Pneumatic system maintenance:

Check the working condition of pneumatic components, cylinders and solenoid valves to ensure that the gas path is smooth and there is no leakage.

Servo system calibration:

According to the requirements of the equipment manual, the servo system is calibrated and adjusted regularly to ensure the running accuracy and stability.

Spare parts replacement:

According to the service life of the equipment and the depletion of spare parts, timely replacement of vulnerable parts and key components, such as seals, valves, etc.

Performance test:

Regularly carry out the performance test and function test of the servo filling machine, confirm whether the functions are normal, adjust the parameters and control logic.

Emergency handling

Troubleshooting:

If the device is faulty or abnormal, shut it down immediately and handle it according to the troubleshooting guide in the device manual.

Maintenance records:

Record the specific content, time and operator of each maintenance, and establish maintenance files to facilitate traceability and analysis of equipment operating conditions.

By strictly implementing the above maintenance procedures, the reliability and stability of the servo filling machine can be improved, the service life of the equipment can be extended, and the continuous operation of the production line and the stability of product quality can be ensured.

FAQ

We are factory located in Shanghai China, welcome to visit our team.

1. Normally 30% deposite payment, balance 70% before shipment.

2. We can provide L/C for special country.

1. For some simple machine, we will install before shipment, no need to do complicate install on customer side.

2. For complicate machine, our engineer is available for going customer side, but the visa fee, round flight ticket, hotel and food are undertaken by customer. Besides, engineer compensation 100USD/Day. Engineer can provide installation services, and also available to teach your operator how to use it.

1. Talk with our sales about your product size and applications, capacity you need per minute, For example 50 pcs/minute. we will provide the right mode for you.

2. Place Order and do the first Payment.

3. Produce and send video for your green light.

4. You do the final Payment

5. Arrange shipment

6. Receive goods.

Yes, we have team to answer your questions and provide technical services China time 8:00AM to 17:00PM. But Please take detail video for the problems you have so that our technical person get well know and provide to you the solutions.

You can cancel order, but the 30% deposit will not return.

Contact Us to Buy

Other Filling Machine for Sale:

Pre-made Bag Granule Flakes Weighing and Packing Machine

Product Information Liquid Filling: Paste filling: Powder filling: Powder Filling Machine: Single Head Rotary Type Linear 2 Heads Powder, Liquid, Paste, Granule weighing and packing machine Customization: We have various types of Pre-made Bag Granule Flakes…Back Sealing Granule Weighing and Packing Machine

Product Information Liquid Filling: Paste filling: Powder filling: Powder Filling Machine: Single Head Rotary Type Linear 2 Heads Powder, Liquid, Paste, Granule filling machine Customization: We have various types of Granule filling machine for sale, and…LMCK liquid bag filling machine Packing

Product Information Liquid Filling: Paste filling: Powder filling: Powder Filling Machine: Single Head Rotary Type Linear 2 Heads Powder, Liquid, Paste, Granule filling machine Customization: We have various types of Granule filling machine for sale, and…LMCK Premade bag packing machine

Product Information Liquid Filling: Paste filling: Powder filling: Powder Filling Machine: Single Head Rotary Type Linear 2 Heads Powder, Liquid, Paste, Granule filling machine Customization: We have various types of Granule filling machine for sale, and…Filling capping machine

The filling and capping machine is specially designed for the new oral liquid easy to draw bottle filling equipment. The design is reasonable, the structure is simple, the operation is convenient and a mechanical device is…LKBK Tea bag packing machine

Product Information Liquid Filling: Paste filling: Powder filling: Powder Filling Machine: Single Head Rotary Type Linear 2 Heads Powder, Liquid, Paste, Granule filling machine Customization: We have various types of Granule filling machine for sale, and…LYLK 3 sides back Sealing Machine

Suitable for Plastic Roll Film Product Information Liquid Filling: Paste filling: Powder filling: Powder Filling Machine: Single Head Rotary Type Linear 2 Heads Powder, Liquid, Paste, Granule filling machine Customization: We have various types of Granule…LYLK Granule filling machine

Product Information Liquid Filling: Paste filling: Powder filling: Powder Filling Machine: Single Head Rotary Type Linear 2 Heads Powder, Liquid, Paste, Granule filling machine Customization: We have various types of Granule filling machine for sale, and…LYLK Double Heads Powder Filling Machine

Powder Filling Machine: Single Head Rotary Type Linear 2 Heads Product Information Powder, Liquid, Paste, Granule filling machine Customization: We have various types of Powder filling machine for sale, and we do customization according to customer’s…LYLK Rotary powder filling machine

Powder Filling Machine: Single Head Rotary Type Linear 2 Heads Product Information Powder, Liquid, Paste, Granule filling machine Customization: We have various types of Powder filling machine for sale, and we do customization according to customer’s…Powder filling machine

There are various types of powder filling machine, we have single head, straight line two heads filling machine and Automatic Rotary Single head powder filling machine. Liquid Filling: Paste filling: Powder filling: Product Information Powder, Liquid,…LYLK Automatic single head powder filling machine

Powder Filling Machine: Single Head Rotary Type Linear 2 Heads Product Information Powder, Liquid, Paste, Granule filling machine Customization: We have various types of Powder filling machine for sale, and we do customization according to customer’s…LYLK Liquid filling machine

Liquid filling machine Customization: We have various types of Liquid filling machine for sale, and we do customization according to customer’s speed and capacity. We can also design and produce the whole production line including the…LYLK Pneumatic Filling Machine

Liquid Paste Powder Product Information Pneumatic Filling Machine: We have various types of Pneumatic Filling Machine for sale, and we do customization according to customer’s speed and capacity. We can also design and produce the whole…LYLK Filling and Stoppering machine

Product Information Filling Stoppering and Capping Machine: We have various types of Filling Stoppering and Capping Machine for sale, and we do customization according to customer’s speed and capacity. We can also design and produce the…LYLK Filling and Capping Machine

Filling and Capping Machine: We have various types of Filling and Capping for sale, and we do customization according to customer’s speed and capacity. We can also design and produce the whole production line including the…LYLK Paste filling machine

Paste filling machine: We have various types of Paste filling machine for sale, and we do customization according to customer’s speed and capacity. We can also design and produce the whole production line including the grinder…LYLK Piston filling machine

Piston filling machine: We have various types of Piston filling machine for sale, and we do customization according to customer’s speed and capacity. We can also design and produce the whole production line including the grinder…LYLK Servo Filling Machine

Servo Filling Machine: We have various types of Semi automatic tube filling machine and Sealing Machine for sale, and we do customization according to customer’s speed and capacity. We can also design and produce the whole…LYLK Semi automatic tube filling machine and Sealing Machine

Semi automatic tube filling machine and Sealing Machine: We have many different model of Semi automatic tube filling machine and Sealing Machine for sale. We can also customize the whole production line including the grinding machine,…LYLK Automatic filling and sealing machine

Automatic filling and sealing machine: We have many different model of Automatic filling and sealing machine for sale. We can also customize the whole production line including the grinding machine, mixing machine, drying machine, conveyor, feeder,…

Coarse Crusher to granules:

Granule mixers:

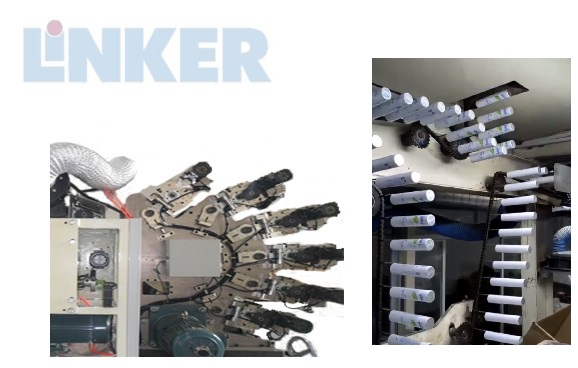

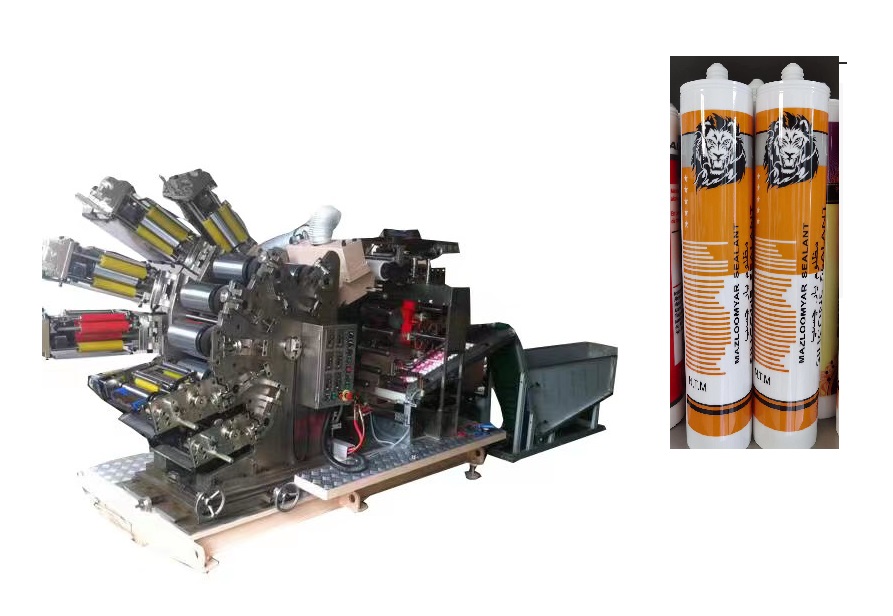

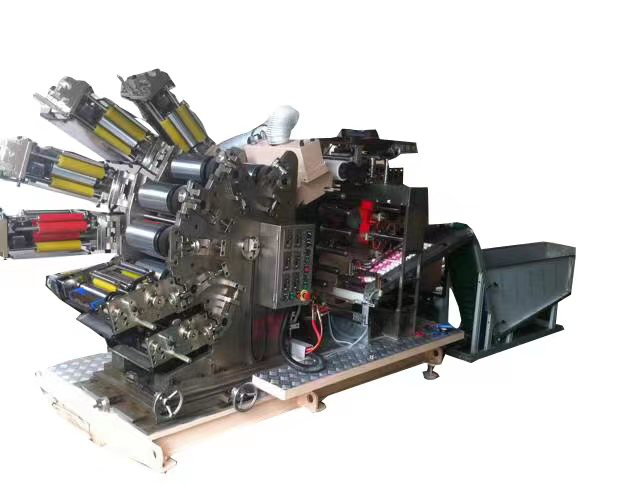

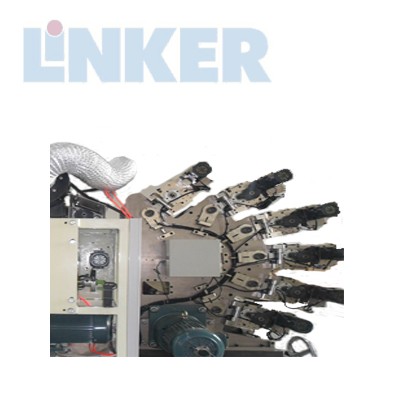

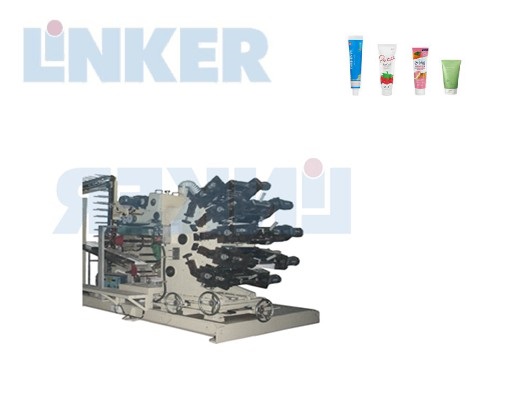

Offset Printer for Sale:

Plastic Tube Printing RV Varnish

RV Varnish is suitable for Elastic and yellowing resistant coating varnish good resistance against solvents, suitable for hot stamping, preventing of diffusion. Does not contain in recipe any environmentally relevant heavy metal sand/or compounds of these elements. Soft tube, hard…LHTK Tube Can offset Aluminum printing Machine

Aluminum printing machine is to print the design picture on the aluminum tubes and cans or caps. It is a 1-8 color offset printing machine high speed about 120pcs per minute. We are manufacturer of offset…Tube Printing Machine

Our 1-8 color Printing Machine are suitable for Various kinds of products: Lip gloss tube printing machine Hard Tube Printing Machine PE Tube Printing Machine Soft Tube Printing Machine: No shoulder Tube Printing Machine PVC tube…Glass Cement 6 Color Hard Tube Printing Machine

GREAT FEATURE Glass Cement Hard Tube 6 Color Printing Machine Applications– Sample of Offset Printer for sale Description: The glass cement hard tube 6 color printing machine is an offset printing machine for fully plastic hard…The Printer Header

Soft tube, hard tube The Printer Header of the 6 Color Soft Tube Printing Machine Applications– Sample of Offset Printer for sale Description: The header of the 6 color soft tube printing machine is produced by…PE tube Six Color Rotating Printer for Sale Price

GREAT FEATURE PE tube 6 Six Color Rotating Printer Applications– Sample of Offset Printer for sale Description: Detailed Product Descriptionfor PE tube 6 Six Color Rotating Printer Quick DetailsType: Offset Printer Condition: New Plate Type: Screen…Dry Oven of 6 Color Printing Machine

GREAT FEATURE Best Dry Oven of 6 Color Printing Machine for Sale Offset Printing Machine Manufacturer We have 1-8 color offset printing machine for soft tube and hard tube. Soft tube used for cosmetic tube, hard…Commercial Offset Printer

Soft tube, hard tube Best Commercial Offset Printer for sale Price Applications– Sample of Offset Printer for sale Offset Printer for sale Video Offset Printer for sale Description: The Commercial Offset Printer is an Offset Printer…6 Color Offset Printing Machine

Soft Tube Hard Tube Best 6 Color Offset Printing Machine for Sale Price Applications– Sample of Offset Printer for sale Offset Printer for sale Video Contact With Us Immediately Tel: +86 2166037855Email: dinglili@linkerprinter.comMobile/What’s app: +86 18019763531…1-8 color Offset Printing Machine

soft tube , hard tube 1-8 color Offset Printing Machine Applications– Sample of Products Video Description: An 8 color offset printing machine is a highly advanced piece of equipment used for commercial printing. As a manufacturer,…

Tube Making Machine:

PE Pipe Extruder -PE single wall Corrugated pipe production line

1. Multiple Drainage Applications Single wall corrugated pipe is ideal for drainage projects where flexibility, light weight and low cost are important. Single wall corrugated pipe has kept farms, golf courses, parks and playing fields…Tube Printing Machine

Our 1-8 color Printing Machine are suitable for Various kinds of products: Lip gloss tube printing machine Hard Tube Printing Machine PE Tube Printing Machine Soft Tube Printing Machine: No shoulder Tube Printing Machine…LYLK Semi automatic tube filling machine and Sealing Machine

Semi automatic tube filling machine and Sealing Machine: We have many different model of Semi automatic tube filling machine and Sealing Machine for sale. We can also customize the whole production line including the…LYLK Automatic filling and sealing machine

Automatic filling and sealing machine: We have many different model of Automatic filling and sealing machine for sale. We can also customize the whole production line including the grinding machine, mixing machine, drying machine,…6 Color Printing Machine

6 color offset printing for Sale: Hs code: 8443139000 can be used for soft tube, cosmetic tube, hard tube, glass cement, bottle, cup, lip gloss, bottle and so on. It’s application is very wide…Tube Filling and Sealing Machine

Soft tube Price: USD12,600 Applications– Sample of Products Tube Filling and Sealing Machine Manufacturer We have 1-8 color offset printing machine for soft tube and hard tube. Soft tube used for cosmetic tube, hard…

Related Post:

Licorice making machine Production Line

Licorice Production Line Process Flow: Washing Licorice root–> cutting Licorice Root into pieces—> Drying machine —> Grinding Machine or Crusher to crush into granule or grind into powder —>Packing Machine(vertical Packing machine for plastic…Classification of packaging machinery

1.1 Composition and characteristics of packaging machinery The national standard GB/T4122.2-2010 “Packaging terminology Part 2: Machinery” defines packaging machinery. Packaging machinery is to complete all or part of the packaging process of the machine,…What is offset printing?

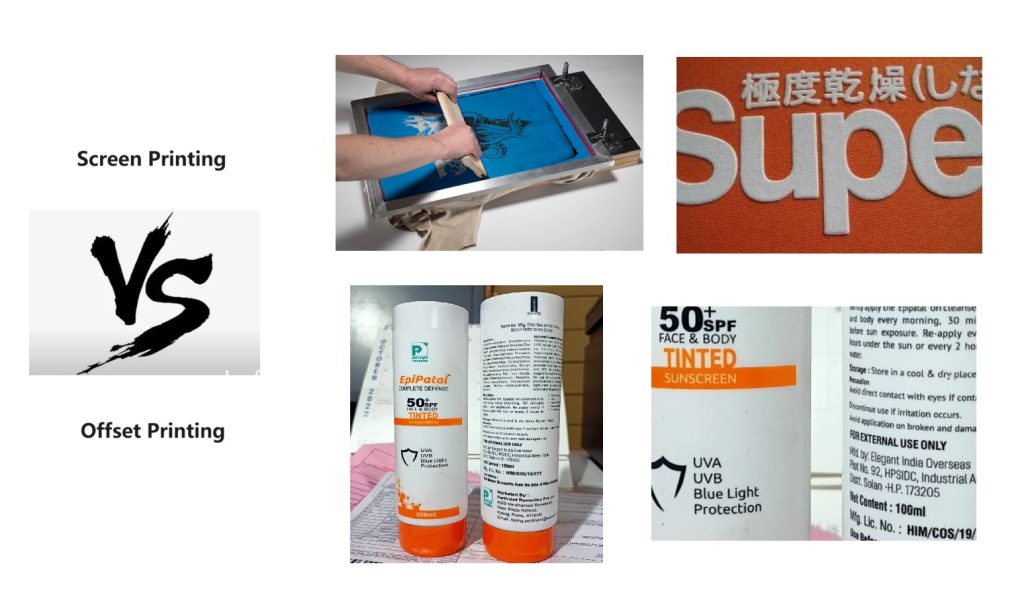

What is offset printing? Offset printing is a kind of lithography, it is very simple to say that offset printing is the use of rubber (rubber blanket) to transfer the graphic on the plate…Which is better offset or screen printing?

Which is better offset or screen printing? The choice of offset printing or screen printing depends on the specific printing needs and application scenarios. Offset printing is suitable for printing ordinary color rich, colorful…