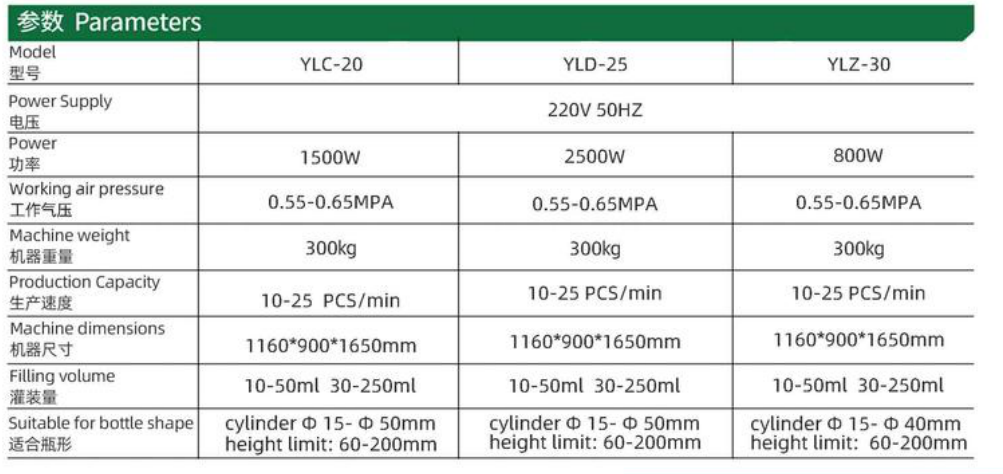

- Production Speed: 10-25pcs/min

- Filling Volume: 10-250ml

- Suitable for bottle shape: Cylinder 15-50mm

- height: 60-200mm

- power: 800-3500kw

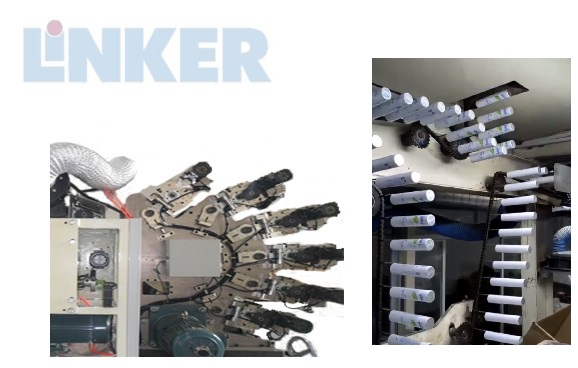

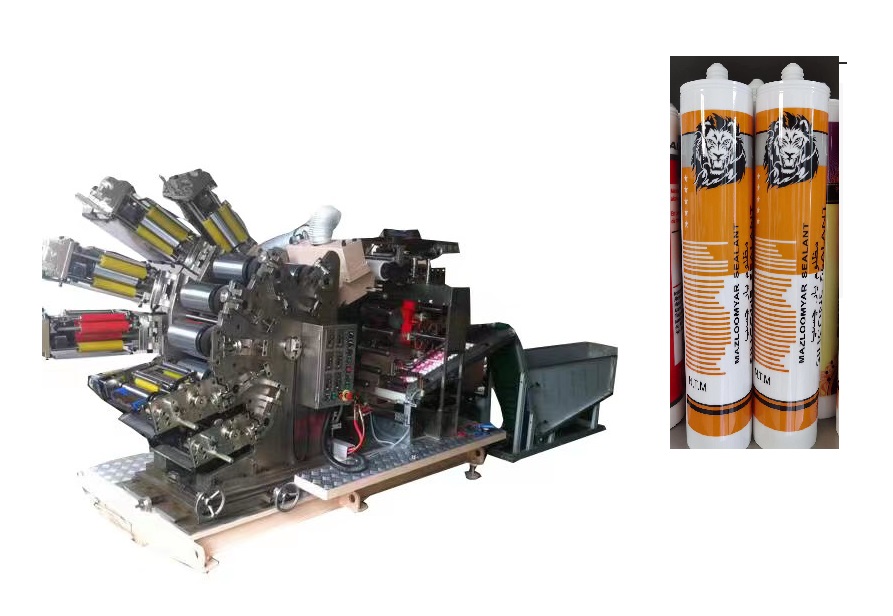

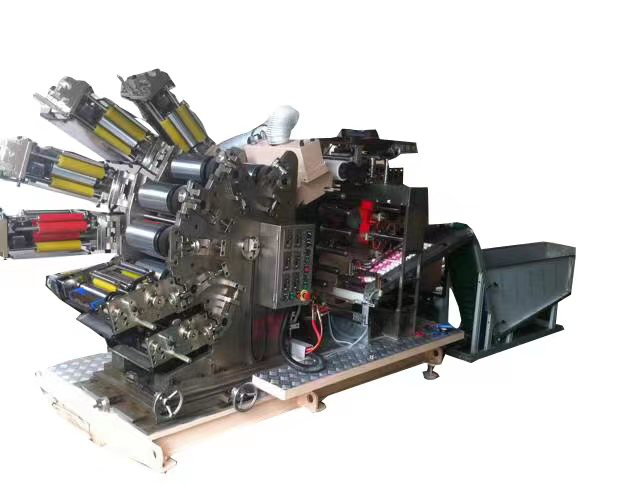

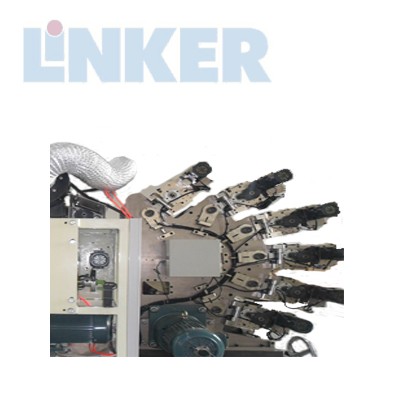

Semi automatic tube filling machine and Sealing Machine:

We have many different model of Semi automatic tube filling machine and Sealing Machine for sale. We can also customize the whole production line including the grinding machine, mixing machine, drying machine, conveyor, feeder, vibrating Screen, Packing Machine… Please contact us for detail proposal and price.

Pre-made Bag Granule Flakes Weighing and Packing Machine

Back Sealing Granule Weighing and Packing Machine

LMCK liquid bag filling machine Packing

LMCK Premade bag packing machine

Filling capping machine

LKBK Tea bag packing machine

LYLK 3 sides back Sealing Machine

LYLK Granule filling machine

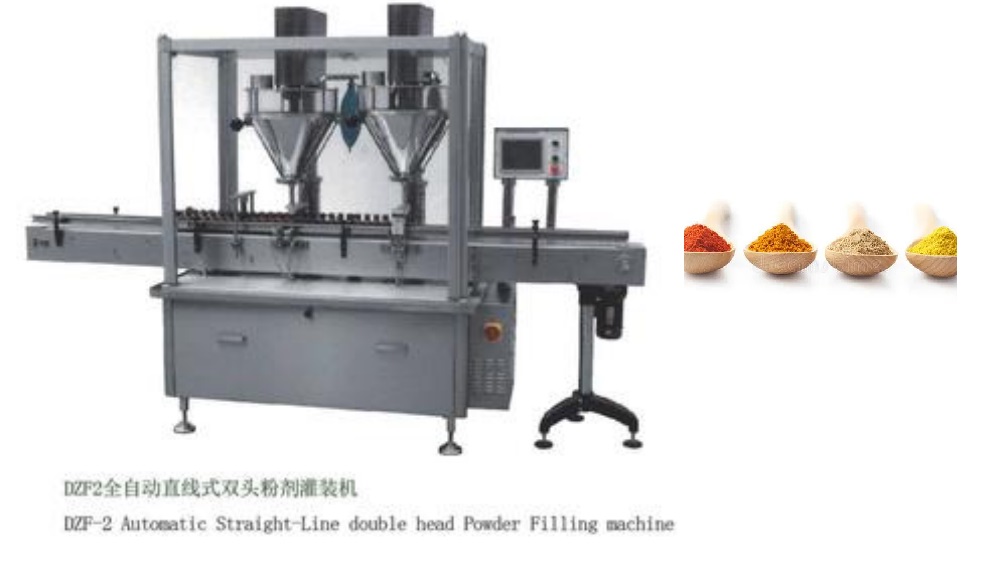

LYLK Double Heads Powder Filling Machine

LYLK Rotary powder filling machine

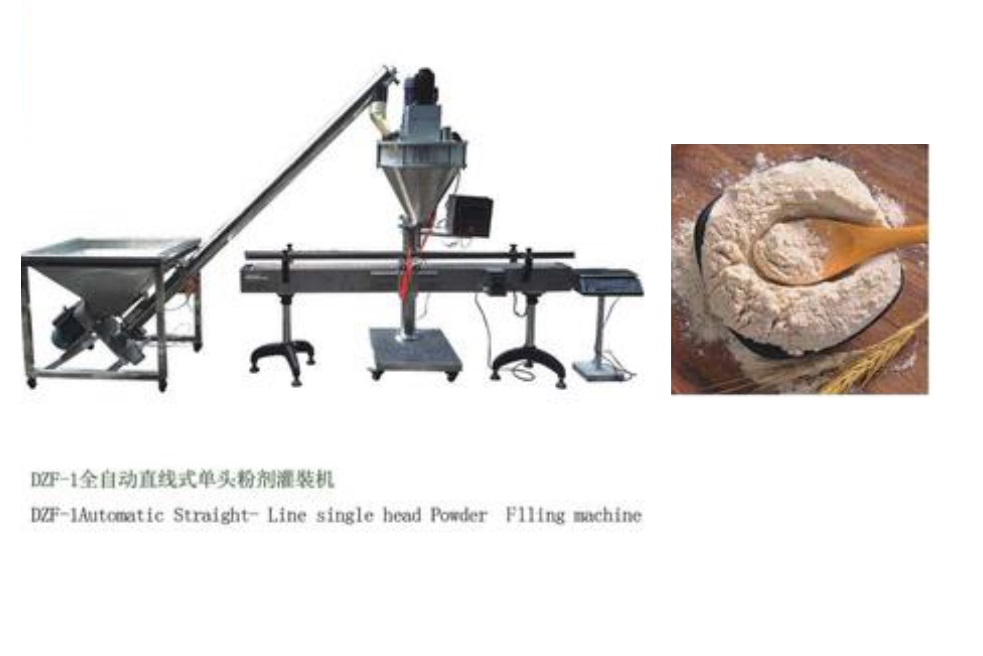

Powder filling machine

LYLK Automatic single head powder filling machine

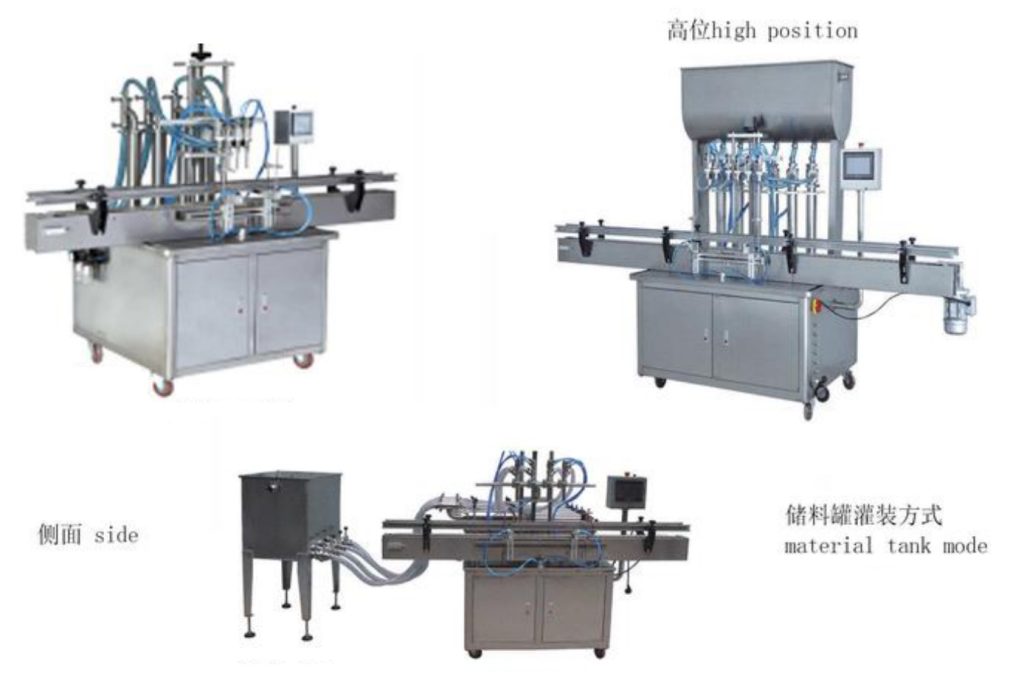

LYLK Liquid filling machine

LYLK Pneumatic Filling Machine

LYLK Filling and Stoppering machine

LYLK Filling and Capping Machine

LYLK Paste filling machine

LYLK Piston filling machine

LYLK Servo Filling Machine

LYLK Automatic filling and sealing machine

Customize Semi automatic tube filling machine and Sealing Machine According to your Capacity:

We can customize the capacity according to your special requirement, we can also customize the Automatic filling and sealing machine connect with your production line (the dimension and width of feeder), for detail contact with our sales for proposal and price.

Videos of Automatic filling and sealing machine:

We have many model of Automatic filling and sealing machine, here show some example:

Product Information

What is Semi automatic tube filling machine and Sealing Machine?

The semi-automatic filling and sealing machine can inject all kinds of paste, paste, viscosity fluid and other materials into the hose smoothly and accurately, and complete the hot air heating in the tube, sealing the tail and marking the batch number and production date.

Automatic filling and sealing machine sealing principle:

The semi-automatic filling and sealing machine can inject all kinds of paste, paste, viscosity fluid and other materials into the hose smoothly and accurately, and complete the hot air heating in the tube, sealing the tail and marking the batch number and production date. The machine has compact structure, manual tube and transmission part are completely closed. The machine automatically completes the whole process of filling, hot melting, sealing, coding and producing. Simple operation, convenient adjustment and disassembly. Especially suitable for the production of multi-specification hose users, easy to adjust. The contact part of the material is made of 316L stainless steel, which is clean, hygienic and fully meets the GMP requirements of drug production. With no tube, no filling, overload protection function.

The sealing machine is widely used in medicine, food, cosmetics, daily chemical products and other industries of plastic pipe, aluminum and plastic composite pipe filling and sealing needs.

Technical parameters of Semi automatic tube filling machine and Sealing Machine:

This series of machines adopts automatic positioning with tube color codes, linkage design for filling.sealing, batch number, and finished product exit, and PLC fully automatic control,The high-definition visible stainless steel outer frame has a reliable transmission system, high filling accuracy, advanced tail sealing form, and effectively improved production capacity. lt has become a necessary filling and sealing machine widely used in industries such as daily chemicals, pharmaceuticals, food, pigments, etc.

Production Line Customization Solution:

We can customize whole automatic production line according to customer special request. According to your special material, capacity requirement and motor and electric cabinet certification requirement, we can customize semi-auto or fully automatic production line for our customer. Please contact us for detail proposal and quotation.

Drying Machine + Grinding Machine + Sifter Machine + Mixing Machine + Packing Machine:

Production Line Customization Videos(See More Videos):

Fertilizer Production Line

Blending Production Line

Wheat Flour Production Line

Factory Information

Factory Information

| Business Type: | Manufacturer/Factory | Main Products: | Mill, grinder, granulator, mixer, Crushing Equipment |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000 Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

Certifications:

Small Machine Packing:

Small machine packed with export fumigation-free wooden cases, goes with bulk shipment or in container.

Large Machine Packing:

Shipment Show Case: Small grinder machine ship for Masala, Pakistan, Kenya, Nepal, India…

Warranty of Machine:

We provide one year warranty for all our machine, but not including the man-made damage. We can provide free spare parts if damage in one year in normal operation. 24hours stand by to solve urgent problems. 3 days of spare parts provide by express. Please specially notice for the motor connection. it should be connect in right way to prevent the motor burnt, take special notice of running machine safely. Machine need to be clean and maintained frequently.

Maintenance of machine:

Hose automatic canning and sealing machine is a common canning equipment, which is widely used in the production line of food, medicine, cosmetics and other industries. In the process of long-term use, some common faults will occur, the following describes several common faults and solutions.

Second, the machine can not start

- Check whether the power supply is connected properly.

- Check whether the power cable is damaged or in poor contact.

- Check whether the fuse in the electronic control box is blown.

- If the above conditions are excluded, it may be that the power switch or motor is damaged and needs to be replaced.

Third, the sealing tail is not firm - Check whether the sealing pressure has been set in place, if not set in place, need to reset.

- Check whether the sealing plate is damaged or deformed. If yes, replace it.

- Check whether there is foreign matter between the sealing plate and the heating wire. If there is, clean it up.

- Check whether the heating wire is loose or broken, if any, it needs to be replaced.

Four, sealing machine leakage - Adjust the sealing temperature and the distance between the sealing plate and the heating wire.

- Check whether the sealing plate is smooth, deformed or damaged.

- Check whether the hose is not sealed due to quality problems and whether it meets the requirements of use.

Five, sealing machine automatic break step does not push rotation - Check whether the transmission chain of the machine is loose.

- Check whether the clamping cylinder fails. If yes, replace it.

- Check whether the automatic step cylinder fails, if any, it needs to be replaced.

The above is the common failure and solution of the hose automatic canned sealing machine, hoping to provide help to the staff who use and maintain the equipment. At the same time, it is recommended that users check the equipment regularly in daily use, discover and solve the fault in time, and ensure the normal operation of the machine.

FAQ

We are factory located in Shanghai China, welcome to visit our team.

1. Normally 30% deposite payment, balance 70% before shipment.

2. We can provide L/C for special country.

1. For some simple machine, we will install before shipment, no need to do complicate install on customer side.

2. For complicate machine, our engineer is available for going customer side, but the visa fee, round flight ticket, hotel and food are undertaken by customer. Besides, engineer compensation 100USD/Day. Engineer can provide installation services, and also available to teach your operator how to use it.

1. Talk with our sales about your product size and applications, capacity you need per minute, For example 50 pcs/minute. we will provide the right mode for you.

2. Place Order and do the first Payment.

3. Produce and send video for your green light.

4. You do the final Payment

5. Arrange shipment

6. Receive goods.