- Production Speed: 0-100 bottles/min

- Filling Volume: 20-5000ml

- Suitable for bottle shape: Various

- Hopper: 100L-500L

- Filling Head: 2-12 heads;

Servo Filling Machine:

We have various types of Semi automatic tube filling machine and Sealing Machine for sale, and we do customization according to customer’s speed and capacity. We can also design and produce the whole production line including the grinder , Blending machine, drying machine, conveyor, feeder, vibrating Screen, Packing Machine… Please contact us quotation, parameters and price.

Pre-made Bag Granule Flakes Weighing and Packing Machine

Back Sealing Granule Weighing and Packing Machine

LMCK liquid bag filling machine Packing

LMCK Premade bag packing machine

Filling capping machine

LKBK Tea bag packing machine

LYLK 3 sides back Sealing Machine

LYLK Granule filling machine

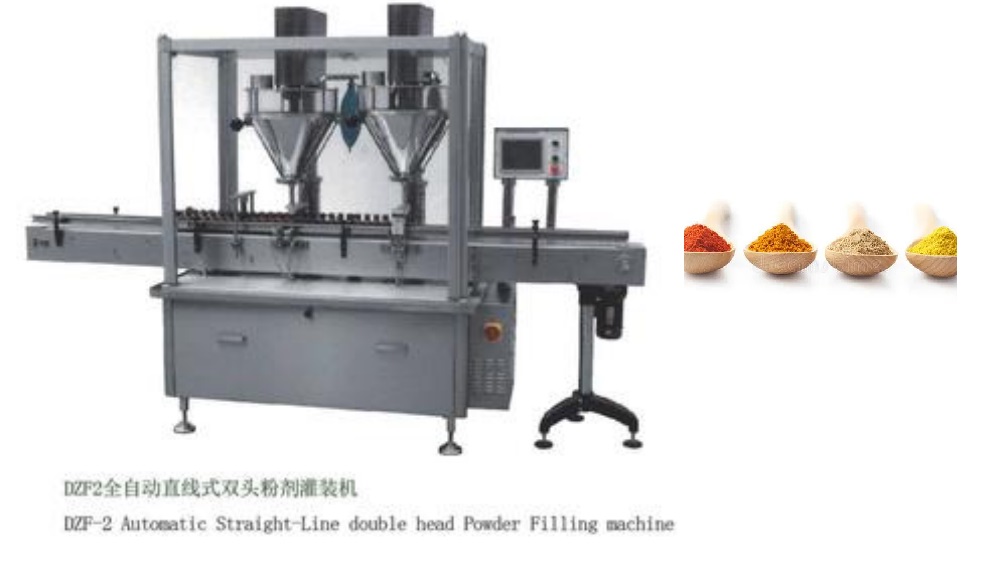

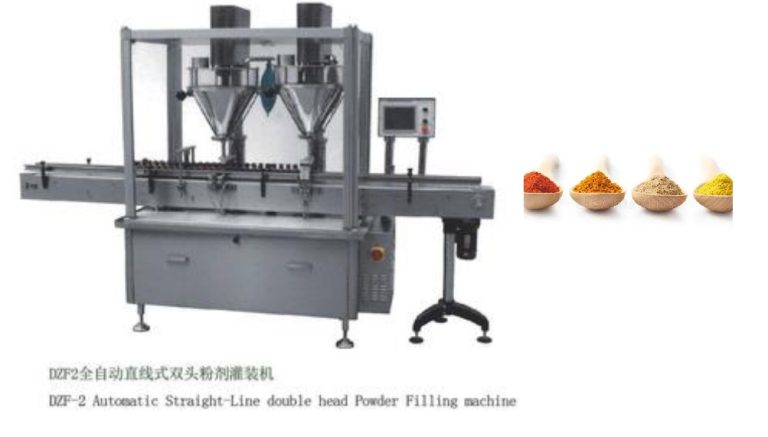

LYLK Double Heads Powder Filling Machine

LYLK Rotary powder filling machine

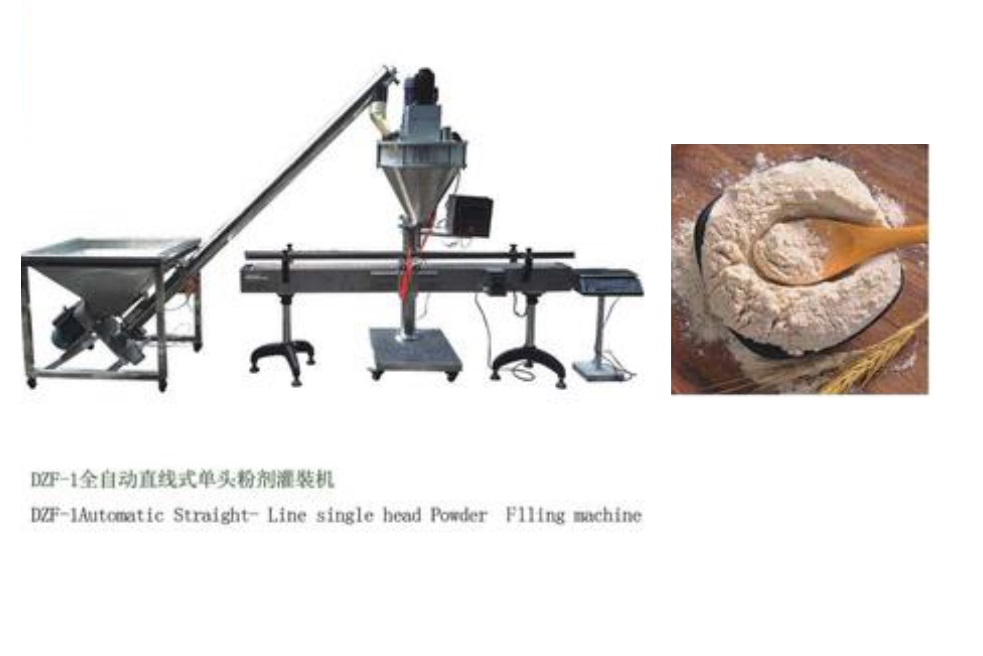

Powder filling machine

LYLK Automatic single head powder filling machine

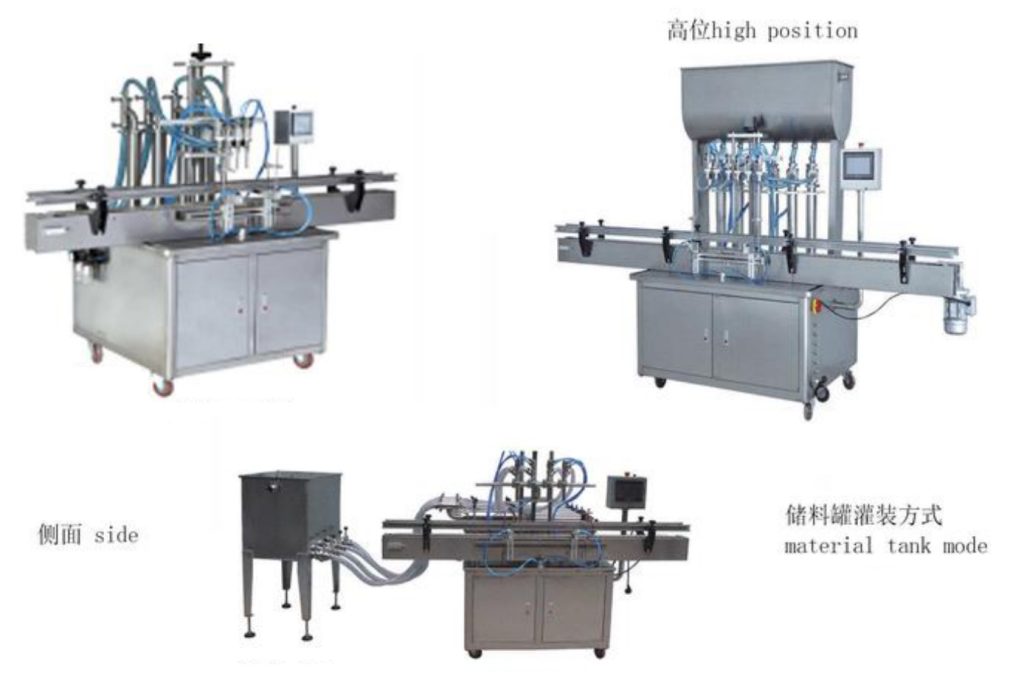

LYLK Liquid filling machine

LYLK Pneumatic Filling Machine

LYLK Filling and Stoppering machine

LYLK Filling and Capping Machine

LYLK Paste filling machine

LYLK Piston filling machine

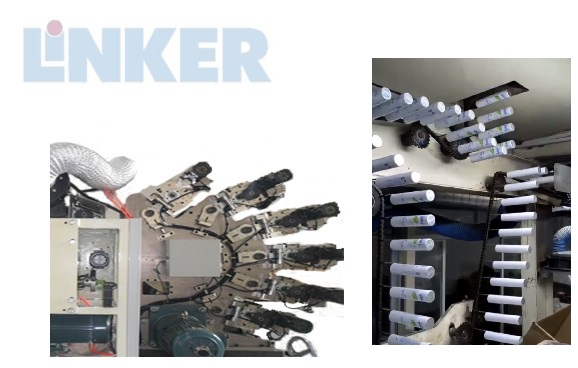

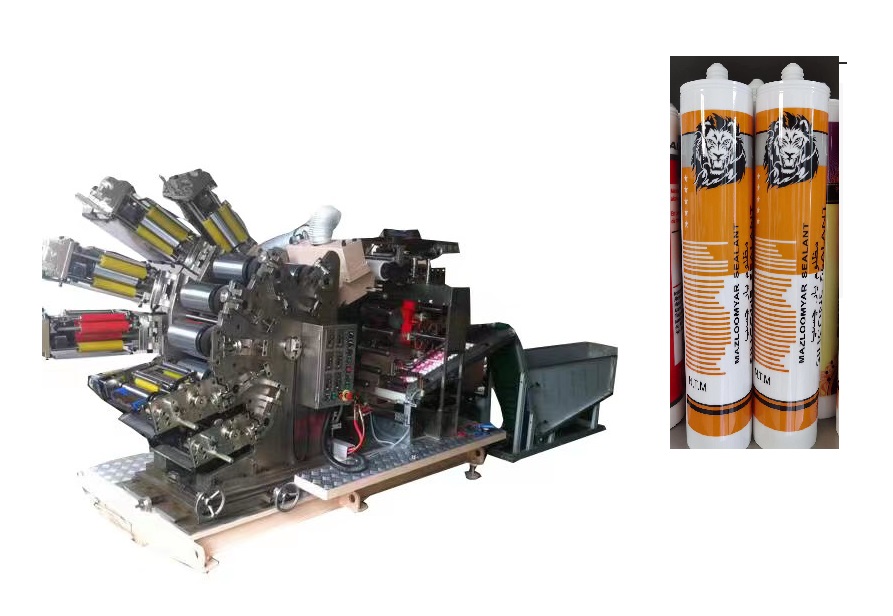

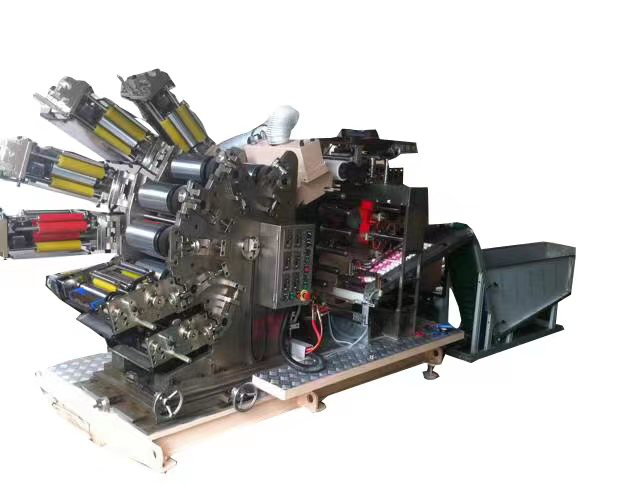

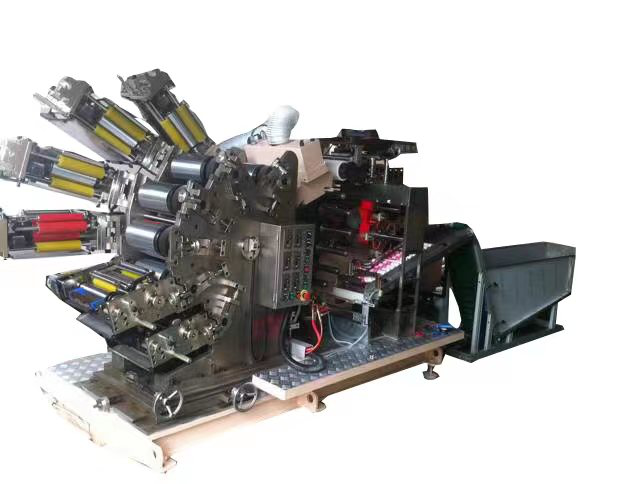

LYLK Semi automatic tube filling machine and Sealing Machine

LYLK Automatic filling and sealing machine

Customize Servo Filling Machine According to your Capacity:

We can customize Servo Filling Machine connect with your production line (the dimension and width of feeder).

Videos of Servo Filling Machine:

We have many model of Servo Filling Machine, here show some example:

Product Information

What is Servo Filling Machine:

In the actual machine equipment, Servo (Servo) is a powerful motion control system. It can control the motion of the device in different speed and position ranges, and maintain the precise positioning of the device. The core of servo system is servo driver, motor and encoder three parts, they through the control scheme, feedback signal and algorithm to achieve high precision motion control.

Servo Filling Machine Working principle:

Servo filling machine is a kind of high precision filling equipment which uses servo system to control the filling amount. The servo filling machine adjusts the position of the filling head by using the servo motor and the actuator loaded with the servo controller to ensure the filling accuracy of each oil barrel. The traditional filling equipment has the problems of unstable filling amount and low precision, but the servo filling machine can achieve high precision filling and minimize the waste of oil.

- Material storage tank: The material storage tank of the filling machine is used to store liquid substances, usually for ordinary stainless steel tanks or customized stainless steel tanks for filling equipment.

- Servo motor: Servo motor is the core component of servo filling machine, with motion controller to achieve accurate control. Its high-precision motion control can achieve accurate quantitative filling, ensure product stability and reduce production costs.

- Pneumatic actuator: The pneumatic actuator is combined with the servo motor to complete the flow control of liquid substances in the pipeline.

- Liquid level sensor: The liquid level sensor is used to detect the liquid height in the storage tank.

- Control system: The control system of the servo filling machine includes a digital display controller, carrier communication ion protector, servo driver and other components, which can realize a variety of functions such as flow monitoring and weight monitoring.

- Liquid storage tank: The liquid storage tank of the filling machine is used to store liquid substances. During the working process, the liquid storage tank moves up and down, controls the flow rate, and is transported to the filling head through the pipeline.

- Filling head: The filling head is the final output part of the servo filling machine, which is used to quantitatively fill the material in the liquid storage tank to the bottle to complete the product filling.

Feature of Servo Filling Machine:

- High precision: servo filling machine adopts full touch screen control system, which can realize high-precision quantitative filling.

- Easy to operate: the servo filling machine operation interface is simple to understand, with a rich user operation manual, for the operation of unskilled personnel can also quickly get started.

- Fast filling speed: The servo filling machine adopts high-precision servo motor, which can realize fast, accurate and efficient motion control of the injector.

- The filling amount can be automatically adjusted: the automatic compression filling system of the servo filling machine can automatically adjust the flow rate and maintain high accuracy in high and low temperature environments.

- Intelligent :Touch filling screen input quantity,weighing automatic feedback system,a key do adjust the filing quantity.convenient and quick light Precision; Servo drive piston filing, to ensure that the fill in grange of high precision and stability, For example,filling volume is 1000ml,the actual filling will accurate士1-2ml

- High speed: Servo drive piston filling, the unique adjustable setup quickly before they are slow filling speed, to ensure that the piston moving distance and filling speed of high-speed stability.

- High Efficiency:Stepper motor driver filling head dive filling.improve the machines control and efficiency Filling volume adjustment is very convenient, has 5 groups of different specifications for storage, quick call directly, without having to repeat.

- Light Performance Adopt another patent of All ou urine sealed piston,put an end to use brings seal leakage from the phenomenon such as material,wear and corrosion resistance.

Technical parameters of Servo Filling Machine:

The GT Series piston-type filling machine is used for filling liquid and pasty liquid products with various viscosity. It is in use of daily chemical, foodstuffs, machine, oil etc. With Taiwan”AIRTAC DELTA With the employment, and Japan SMC electrical elements with German “SICK” FESTO photoeletric switch. the machine is excellent in quality, lasting and steady in performance and easy in maintenance. Besides, the machine, prowled with a counter, is accurate in filling volume,easy in adjustment with no bottle failing to be filed parts contact material is 316 stainless steel,can be customized drip proof device lifting, by fast lo slow filling speed, at the some time Tilling and rise.

There are several types of Servo Filling Machine:

1. Servo liquid filling machine:

Servo liquid filling machine is using the servo system to control the accuracy of filling volume and speed. Compare with normal liquid filling machine without servo system, this type of filling machine is much more accuracy of controlling. This is used in medicine, which with high requirement of filling volume. LK have many types of servo liquid filling machine type suitable for round bottle, square bottle, special shaped bottle, small bottle, big bottle, tubes, oil tanks, can, tin, aluminum tube, soft tube, hard tube, bag, pouch bag, stand bag, and so on… the application is very wide. Suitable for various industries, chemical, food, medicine, and so on. Various liquid types of materials, drinks, waters, wine, liquid medicine, food liquid, lotion, and so on…All these materials are suitable to fill in these machine. We can customize according to your capacity and speed, and material the whole production line.

2. Automatic two head servo filling machine:

Two Dead servo filling machine or more than two heads are used in high capacity requirement to meet customer speed request. It depends on how many pcs you want to finish within one minute. Two heads design or more than two heads design is according to your detail speed request. And this can also reduce your production time to increase the produce efficiency. LK have many types of two head servo filling machine type suitable for round bottle, square bottle, special shaped bottle, small bottle, big bottle, tubes, oil tanks, can, tin, aluminum tube, soft tube, hard tube, bag, pouch bag, stand bag, and so on… the application is very wide. Suitable for various industries, chemical, food, medicine, and so on. Various liquid types of materials, drinks, waters, wine, liquid medicine, food liquid, lotion, and so on…All these materials are suitable to fill in these machine. We can customize according to your capacity and speed, and material the whole production line.

3. Servo pump filling machine:

Servo pump filling machine have semi auto type and automatic servo gear pump liquid filling machine type. The pump or gear control is a kind of control way of volume.

4. Automatic servo piston liquid filling machine:

Piston liquid filling machine is suitable for various viscosity materials, with the help of servo system, it have high accuracy feature, very suitable for various materials in production of filling process.

5. Servo based tube filling machine:

Tube filling machine is for filling material into soft tube, hard tube, cosmetic tube, medicine tube and so on. The tube parameters are various, diameter from small to large all can customized only need to change the mode with different tube size. This is adjustable and convenience to install when there are spec changes. Customer can book several diameters modes, such as 18mm, 20mm, 25mm, 30mm, 35mm, 40mm, 45mm, 50mm and so on. We can all customize according to your tube size and speed.

6. Automatic servo type liquid filling machine:

Servo Type also have semi-automatic type, you can control by manual, but the automatic servo type is the major one in liquid filling machine. Which helps a lot in improving the working efficiency.

The servo control system plays an important role in the filling accuracy of the servo filling machine. In the filling process, the servo control system can be based on the preset filling amount, through real-time detection, and adjust the position of each oil barrel to ensure that the filling amount of each oil barrel can reach the preset value. Once the filling amount is detected to exceed the preset value, the servo controller sends a signal to control the servo motor to stop rotating in order to control the filling error.

In summary, the servo filling machine can use the servo control system to control the filling amount of the oil drum with high precision, which greatly improves the filling efficiency and accuracy, and gradually replaces the traditional filling equipment.

Production Line Customization Solution:

We can customize whole automatic production line according to customer special request. According to your special material, capacity requirement and motor and electric cabinet certification requirement, we can customize semi-auto or fully automatic production line for our customer. Please contact us for detail proposal and quotation.

Air Below Washing Machine + Sterilize Machine + Filling Machine + Metal Detector + Check Weight + Capping Machine + Labeling Machine + Label Shrink Film

Drying Machine + Grinding Machine + Sifter Machine + Mixing Machine + Packing Machine:

Factory Information

Factory Information

| Business Type: | Manufacturer/Factory | Main Products: | Mill, grinder, granulator, mixer, Crushing Equipment |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000 Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

Certifications:

Machine Packing:

Small machine packed with export fumigation-free wooden cases, goes with bulk shipment or in container.

Warranty of Machine:

We provide one year warranty for all our machine, but not including the man-made damage. We can provide free spare parts if damage in one year in normal operation. 24hours stand by to solve urgent problems. 3 days of spare parts provide by express. Please specially notice for the motor connection. it should be connect in right way to prevent the motor burnt, take special notice of running machine safely. Machine need to be clean and maintained frequently.

Maintenance of machine:

Servo filling machine as an important equipment in the automated production line, its maintenance is very important to ensure production efficiency and product quality. The following is an overview of the general servo filling machine maintenance procedures:

Routine maintenance

Cleaning and inspection:

Before and after each shift, clean the external surface of the servo filling machine, especially the working area and transmission components.

Check for debris and foreign objects around the machine and keep the working environment clean and tidy.

Lubrication:

According to the requirements of the equipment manual, regularly fill the lubricating parts of the servo filling machine with appropriate lubricating oil or grease.

Be careful not to over-lubricate or leak to avoid contaminating the product.

Check the transmission components:

Regularly check the tension and wear of the drive belt, chain and gear, and adjust or replace damaged parts in time.

Cleaning and replacing filters:

Regularly clean or replace the servo filling machine air filter, hydraulic filter, etc., to ensure the smooth system and reduce the failure rate.

Scheduled maintenance

Electrical parts inspection:

After powering off the device, check that electrical connections, switches, control panels, and sensors are secure and working properly.

Check cable and wiring wear regularly to avoid short circuit or open circuit.

Pneumatic system maintenance:

Check the working condition of pneumatic components, cylinders and solenoid valves to ensure that the gas path is smooth and there is no leakage.

Servo system calibration:

According to the requirements of the equipment manual, the servo system is calibrated and adjusted regularly to ensure the running accuracy and stability.

Spare parts replacement:

According to the service life of the equipment and the depletion of spare parts, timely replacement of vulnerable parts and key components, such as seals, valves, etc.

Performance test:

Regularly carry out the performance test and function test of the servo filling machine, confirm whether the functions are normal, adjust the parameters and control logic.

Emergency handling

Troubleshooting:

If the device is faulty or abnormal, shut it down immediately and handle it according to the troubleshooting guide in the device manual.

Maintenance records:

Record the specific content, time and operator of each maintenance, and establish maintenance files to facilitate traceability and analysis of equipment operating conditions.

By strictly implementing the above maintenance procedures, the reliability and stability of the servo filling machine can be improved, the service life of the equipment can be extended, and the continuous operation of the production line and the stability of product quality can be ensured.

FAQ

We are factory located in Shanghai China, welcome to visit our team.

1. Normally 30% deposite payment, balance 70% before shipment.

2. We can provide L/C for special country.

1. For some simple machine, we will install before shipment, no need to do complicate install on customer side.

2. For complicate machine, our engineer is available for going customer side, but the visa fee, round flight ticket, hotel and food are undertaken by customer. Besides, engineer compensation 100USD/Day. Engineer can provide installation services, and also available to teach your operator how to use it.

1. Talk with our sales about your product size and applications, capacity you need per minute, For example 50 pcs/minute. we will provide the right mode for you.

2. Place Order and do the first Payment.

3. Produce and send video for your green light.

4. You do the final Payment

5. Arrange shipment

6. Receive goods.