GREAT FEATURE

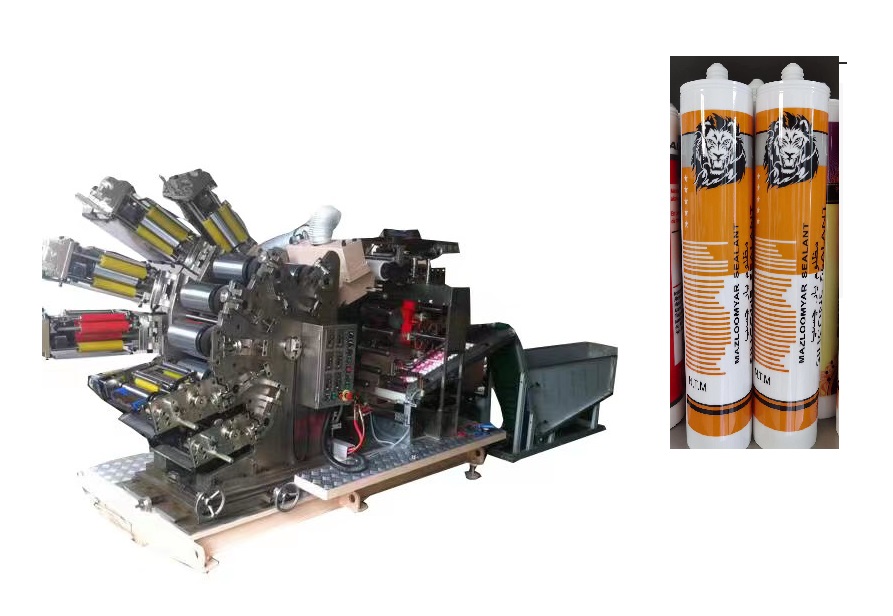

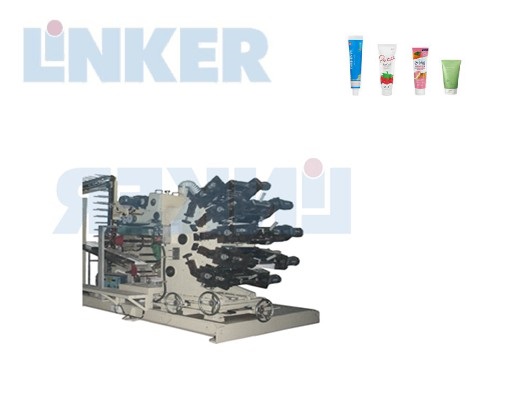

Glass Cement Hard Tube 6 Color Printing Machine

- Max Speed: 120pcs/minute (Depends on products)

- Color: 1-8 color, customization

- Suitable for : Cosmetic tubes, Silicon Sealants, Aluminum Caps, Paper Cups

- Product Diameter Scope:10~120mm

- Motor Power: Driving Wheel 3.7kw; Driver for printing plate 2.2kw; driver chain 2.2kw; Driver for ink stick 0.06kw

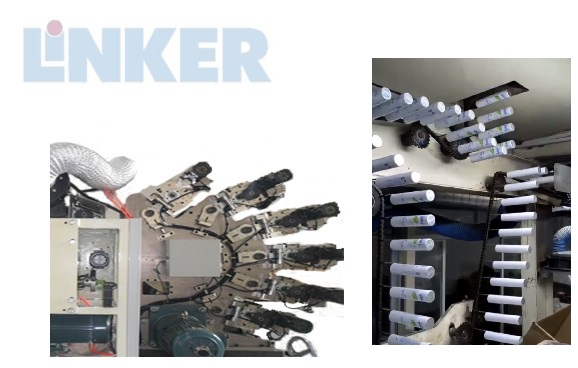

Applications– Sample of Offset Printer for sale

Description:

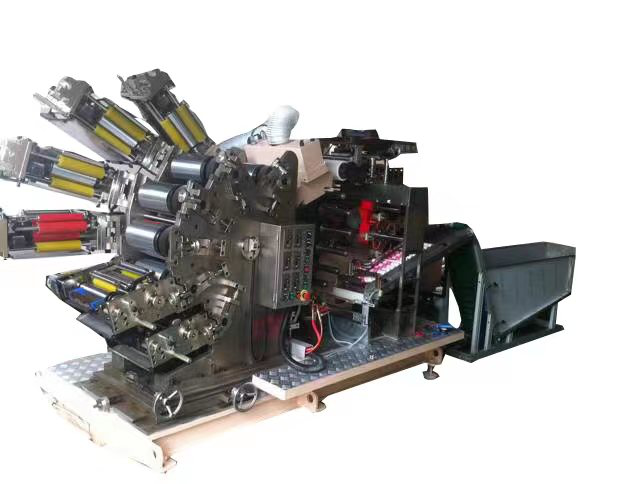

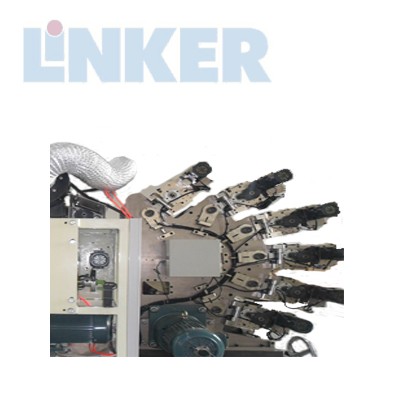

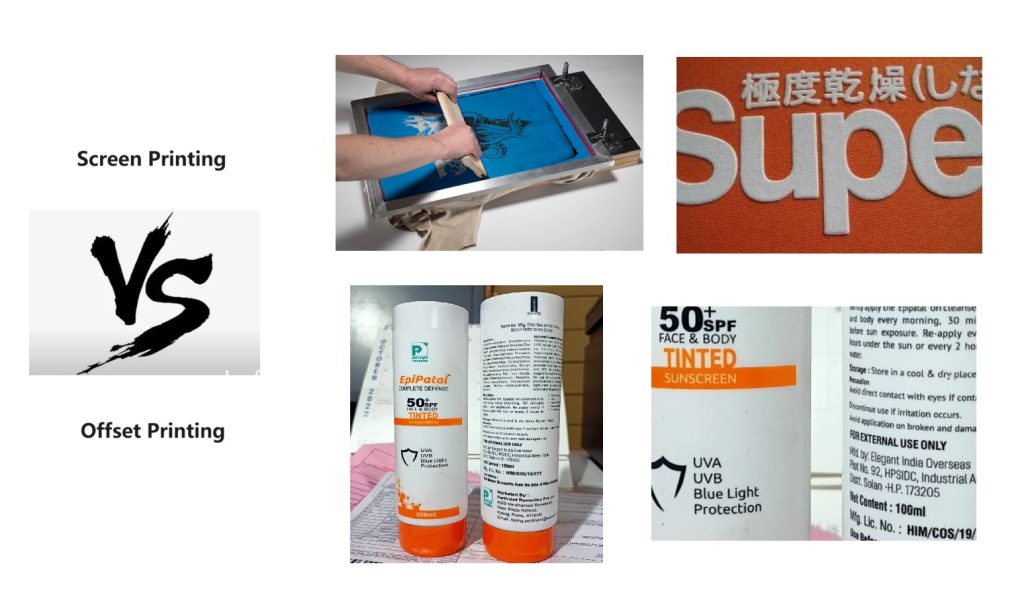

The glass cement hard tube 6 color printing machine is an offset printing machine for fully plastic hard tube. It’s also called offset printing machine or 6 color rotary printing machine. The glass cement hard tube 6 color printing machine is specially designed for plastic hard tube. It mainly consists of two portions: printing machine header and oven.For the header of the printing machine is functioned to print the pictures on the hard tube, after the printing, it goes to the oven for dry. The color of the oven can customize according to customer request.

I will give the best quotation to you at the first time. If there is anything we can do for you, we shall be more than pleased to do so. Hope we can build good cooperation with you. Looking forward to your enquiry!

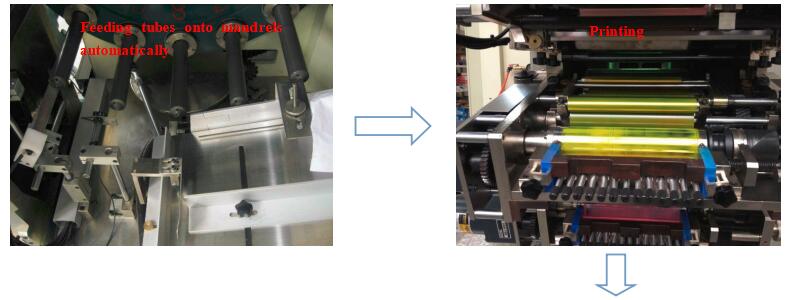

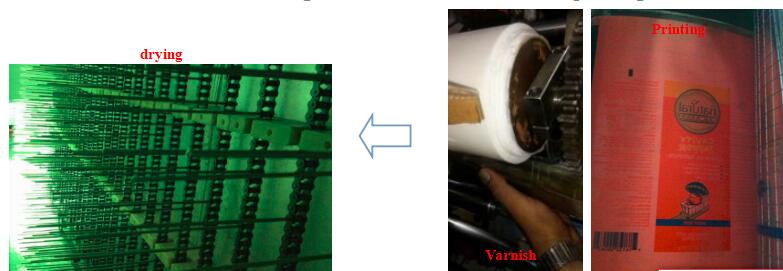

Process Flow:

Mechanical arm grab the glass cement hard tube to feed the tube onto the mandrel, hard tubes goes to the 6 color printing axis and do the printing, then goes to the varnish and oil axis, after finish the varnish, hard tube will transferred to the oven automatically, and when comes out from the oven, hard tube was dried.

Advantages:Excellent Functions of the hard tube 6 color printing machine:

- Excellent performance in printing gradient ramp

- Excellent performance in printing human face

- Excellent performance in clear and small words

- The hard tube 6 color printing machine is designed compactly, built-in registration system(electable)、UV curing system or heater(electable).Maximum printing speed is 80pcs per minute. The configured systems:PLC and touch screen systems, auto feeding and downloading systems, flaming system(double torches for special PP plastic),mechanical synchronous drive system,”No-piece-No-printing”sensor, mechanical fixing system for printing.

- The hard tube 6 color printing machine adopted the horizontal rotating mechanical synchronous drive system,work-piece be rotated 360 degree to finish the printing; which becomes the high printing capacity line because the feeding system. The perfect design will satisfy many customers’ different requirement for the high quality products.

- Selective choice for corona system and flaming system: Configurated with both corona and flaming system, can use any one when producing the hard tube. Varnish function: Varnish can use UV varnish or other types of varnish, be aware of that if use the UV varnish, must use the UV lamp in the oven to dry the varnish. If the varnish type is not UV varnish, then no need to open the UV lamp in the oven, otherwise, the hard tube may comes out bent.

Main use of glass cement

hard tube 6 color printing machine:

It is used for printing 1-6 color(s) and drying tubes.

Features

1).Employ precise decollator of 180mm width between centers from TAIWAN to drive the printing table, so as to ensure its stability & long service life under high speed working.

2). To the complex process of shifting tubes from printing table to the chain, we also employ TAIWAN decollator and special made rolling screw rod, to maintain the stability of the work.

3). There is only one data cable connecting the printer and dryer, which brings future convenience to the following situation: if the printer is placed downstair while the dryer is placed on upstairs, the tubes won’t need a lifting machine to convey to upstairs for drying, so as to save manpower.

4). Direct heating of chamber type of dryer reduces heat loss.

5). Gears using in printer is of fine made, which ensure its precision and service life, so as to help precision of chromatography greatly.

6). Dryer is made up of 2 parts, first part is for laminar current and UV treatment, second part is for infrared heating; thanks to a special laminar current, the gloss oil works well, which reduces the count on the smoothness of gloss oil wheel, so as to reduce the grinding to the gloss oil wheel.

7). Back moving design of printing table, when there is no tube on a printing stick, the whole printing table will move backward for 5mm, so as to avoid the contact of ink and printing rod.

8). Matured headless printing helps to reduce the wastage of large area printing, as well as reduce 2 processes–welding & head cutting–for the oval tubes.