RV Varnish is suitable for Elastic and yellowing resistant coating varnish good resistance against solvents, suitable for hot stamping, preventing of diffusion. Does not contain in recipe any environmentally relevant heavy metal sand/or compounds of these elements.

Soft tube, hard tube, glass cement tibe, PE tube, PP tube, Plastic Tube

Three-in-one Tube varnish

- Appearance: Liquid

- Type and proportion: acrylic monomer: curing agent: diluent 10:1:3

- Composition: epoxy acrylic monomer 70%, hardener 8%, diluent 22%

- Chemical name: Temperature curing varnish

- Price: Varnish: USD 15/KG

- Hardener USD 15/KG

- Diluent: USD 10/KG

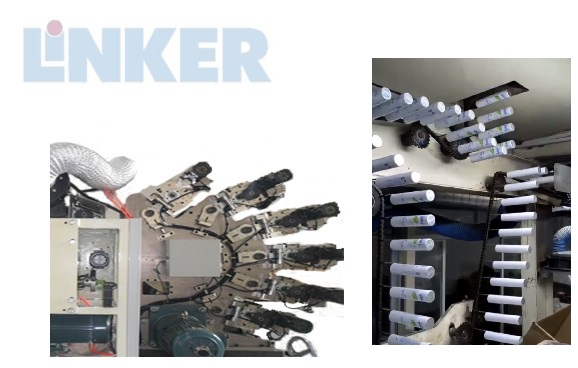

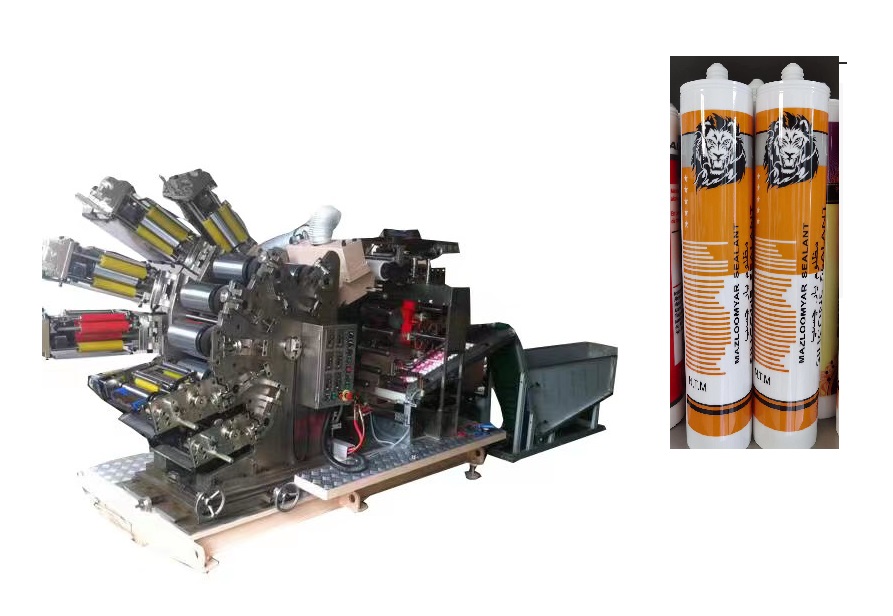

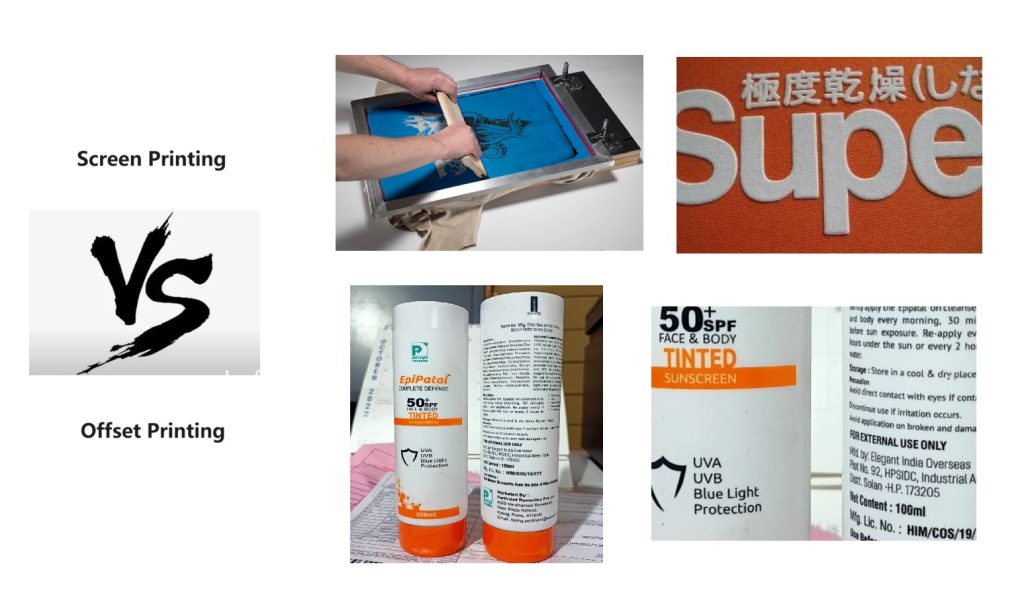

Applications– Sample of Offset Printer for sale

Name and Logo

- Chemical name: Temperature curing varnish

- Recommended use of this product: plastic hose surface rolling coating or substrate spraying

| Hazardous ingredients and Name | Chemical Abstracts Agency registration number | Content |

| Epoxy Acrylic Resin | ————- | 70% |

| Hardener | ————- | 8% |

| Diluent | ————- | 22% |

Risk Overview

- Hazard Category: 3 (flammable liquid)

- Invasion route: inhalation, ingestion, absorption through the skin

- Health hazards: irritation to the skin and mucous membranes, long-term contact can cause skin damage, causing red rash.

- Environmental hazards: The mixture may be harmful to the environment and special attention should be paid to water.

- Deflagration hazard: flammable and explosive chemicals whose vapors and liquids are flammable and can cause fire or explosion in case of fire.

Emergency Treatment

- Skin contact: Wash with plenty of water or soapy water. If irritation persists, seek medical attention;

- Eye contact: Immediately turn up the upper and lower eyelids, rinse with plenty of water for more than 15 minutes, if necessary, send to the doctor for treatment;

- Inhalation: Move the patient to fresh air, provide oxygen immediately if breathing is difficult, if breathing stops, immediately give artificial respiration, and send to the doctor for treatment;

- Ingestion: induce vomiting, if the patient is awake, give milk or water to dilute gastric juice, keep warm, keep rest, and send to the doctor for treatment.

Fire-fighting measures

- Dangerous characteristics: the mixture of steam and air can form an explosive mixture, which can cause combustion in case of open fire and release toxic gases.

- Harmful combustion products: carbon monoxide, carbon dioxide, unknown organic compounds are produced during thermal decomposition

- Fire extinguishing method: Use foam, dry powder, or carbon dioxide extinguishing agent

- Fire-fighting precautions and measures: Firemen should use full body fire protective clothing and wear self-contained breathing apparatus to prevent toxicity or irritation

- The use of water to extinguish a fire is ineffective.

Leakage Emergency Treatment

Emergency treatment: personnel quickly evacuate the contaminated spill area to the safety zone, cut off the fire source, emergency treatment personnel wear fire clothing, use non-ignition tools to collect and plug the leak. Prevent access to sewers.

1.Extinguish ignition source, prohibit smoking, open flame, spark in hazardous areas

- Try to stop leakage without endangering the safety of personnel

- A small amount of leakage: with sand or soil to absorb the spilled liquid, and then placed in the container for future treatment.

- A large amount of leakage: use sand or soil to prevent the spread of spilled liquid, such as spilled liquid into the sewer, there is a potential risk of explosion or toxicity, should immediately notify the relevant authorities (especially the fire Department). If possible, transfer the spilled liquid to a tank for later recycling

Operation Handling and Storage

Dispose of:

- The operation should be handled gently, strictly prevent collision.

- Away from high temperature and fire, prevent direct sunlight.

- Avoid eye, skin contact, do not inhale the steam generated.

Storage:

- Can not be stored with oxide.

- Keep the container sealed and store in a cool and well-ventilated place.

- Avoid high temperature and direct sunlight (warehouse temperature should not exceed 30℃).

- this kind of substance will have a chemical reaction after seeing ultraviolet light and sunlight, storage, please keep away from light.

- storage area lighting, ventilation equipment should be explosion-proof type.

- storage area lighting, ventilation equipment should be explosion-proof type

Contact Control/Personal Protection

- Maximum permissible concentration: China (MAC) No data available

- Engineering control: The workplace should be well ventilated.

- Personal protective equipment

- Respiratory protection: Wear a qualified respirator

- Eye protection: wear chemical safety protective glasses

- Body protection: wear protective clothing

- Hand protection: Follow general precautions for solvent-resistant gloves such as rubber gloves.

- Other: Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes, maintain good hygiene habits.

Physicochemical property:

State of matter: Liquid Color: colorless or light yellow Odor: has a special odor

| (℃)Boiling point | Unmeasured | ( ℃)Melting point | Unmeasured |

| (℃)Flash point | More than 23℃ | (℃)Autoignition temperature | Unmeasured |

| (g/cm3)20℃Density | 0.95-1.15 | (mbar30℃)Vapour pressure | Unmeasured |

- Explosion limit (% volume) :

- Lower limit: undetermined,

- Upper limit: undetermined

- Solubility: insoluble in water, soluble in benzene, alcohol, ether and other organic solvents.

Stability and Reactivity

| Stability: Stable |

| Forbidden compound with: strong oxidizing agent |

| Avoid contact conditions: static electricity, flame, spark, heat source |

| Polymerization hazard: No polymerizationDecomposition products: carbon monoxide and carbon dioxide will be produced when thermal decomposition |

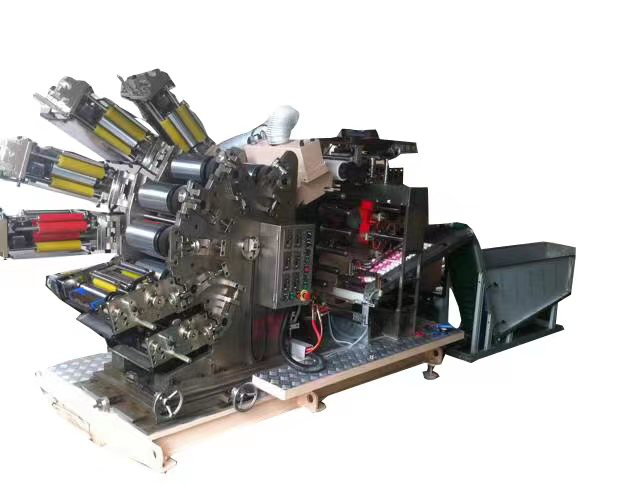

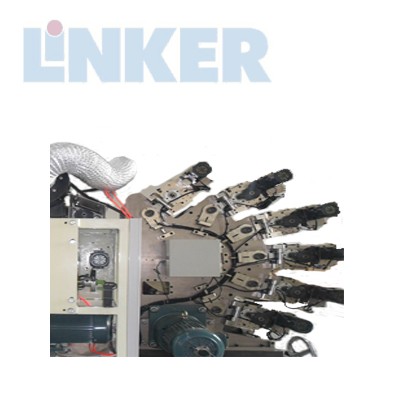

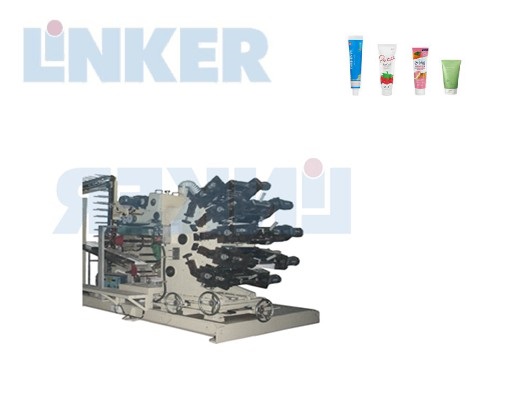

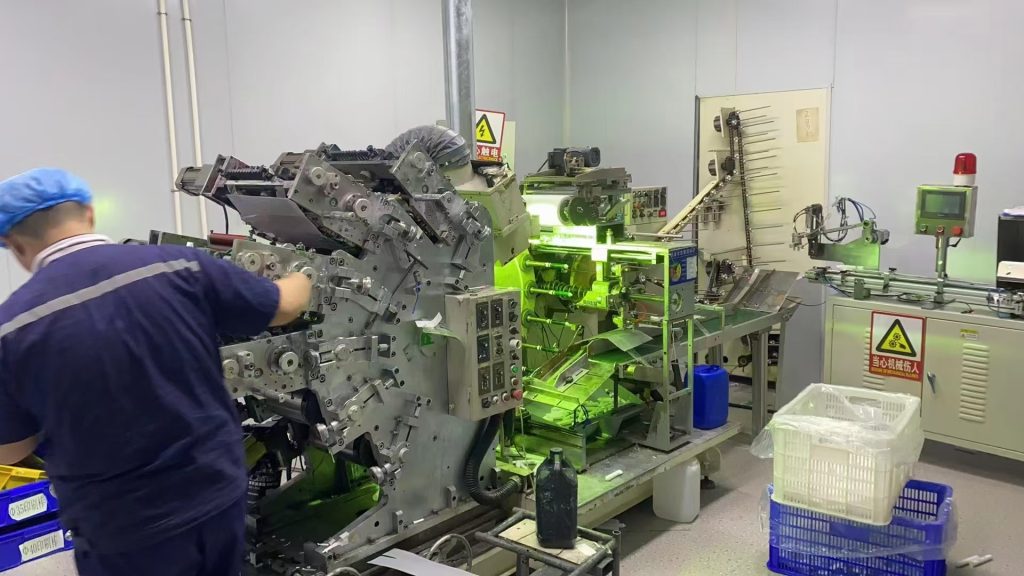

Suitable for Tube Printing Machine:

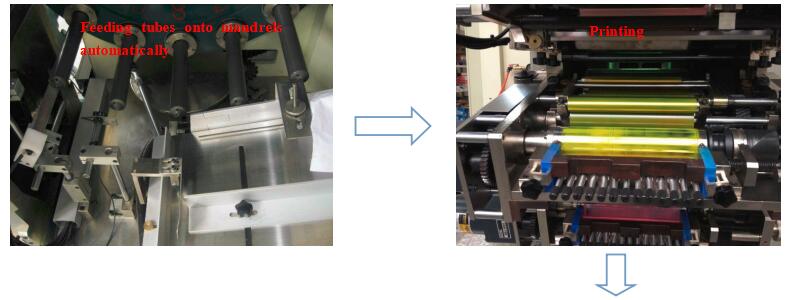

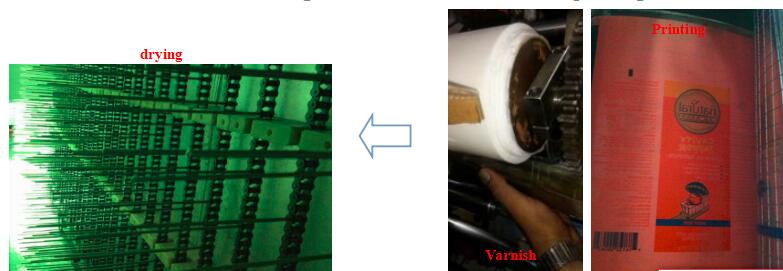

Process Flow:

Mechanical arm grab the glass cement hard tube to feed the tube onto the mandrel, hard tubes goes to the 6 color printing axis and do the printing, then goes to the varnish and oil axis, after finish the varnish, hard tube will transferred to the oven automatically, and when comes out from the oven, hard tube was dried.

Advantages:Excellent Functions of the hard tube 6 color printing machine:

- Excellent performance in printing gradient ramp

- Excellent performance in printing human face

- Excellent performance in clear and small words

- The hard tube 6 color printing machine is designed compactly, built-in registration system(electable)、UV curing system or heater(electable).Maximum printing speed is 80pcs per minute. The configured systems:PLC and touch screen systems, auto feeding and downloading systems, flaming system(double torches for special PP plastic),mechanical synchronous drive system,”No-piece-No-printing”sensor, mechanical fixing system for printing.

- The hard tube 6 color printing machine adopted the horizontal rotating mechanical synchronous drive system,work-piece be rotated 360 degree to finish the printing; which becomes the high printing capacity line because the feeding system. The perfect design will satisfy many customers’ different requirement for the high quality products.

- Selective choice for corona system and flaming system: Configurated with both corona and flaming system, can use any one when producing the hard tube. Varnish function: Varnish can use UV varnish or other types of varnish, be aware of that if use the UV varnish, must use the UV lamp in the oven to dry the varnish. If the varnish type is not UV varnish, then no need to open the UV lamp in the oven, otherwise, the hard tube may comes out bent.

Main use of glass cement

hard tube 6 color printing machine:

It is used for printing 1-6 color(s) and drying tubes.

Features

1).Employ precise decollator of 180mm width between centers from TAIWAN to drive the printing table, so as to ensure its stability & long service life under high speed working.

2). To the complex process of shifting tubes from printing table to the chain, we also employ TAIWAN decollator and special made rolling screw rod, to maintain the stability of the work.

3). There is only one data cable connecting the printer and dryer, which brings future convenience to the following situation: if the printer is placed downstair while the dryer is placed on upstairs, the tubes won’t need a lifting machine to convey to upstairs for drying, so as to save manpower.

4). Direct heating of chamber type of dryer reduces heat loss.

5). Gears using in printer is of fine made, which ensure its precision and service life, so as to help precision of chromatography greatly.

6). Dryer is made up of 2 parts, first part is for laminar current and UV treatment, second part is for infrared heating; thanks to a special laminar current, the gloss oil works well, which reduces the count on the smoothness of gloss oil wheel, so as to reduce the grinding to the gloss oil wheel.

7). Back moving design of printing table, when there is no tube on a printing stick, the whole printing table will move backward for 5mm, so as to avoid the contact of ink and printing rod.

8). Matured headless printing helps to reduce the wastage of large area printing, as well as reduce 2 processes–welding & head cutting–for the oval tubes.

Waste Treatment:

- Waste disposal method: controlled inciNature of waste: hazardous waste

- neration method

Transport information:

- UN NO.:1293

- Package:7 Type:Ⅲ

- Packing method: small opening steel drum; Plastic bottles or metal buckets (cans) outside wooden cases. Transportation precautions: summer should be transported in the morning and evening to prevent sunlight exposure. The transport runs on the prescribed route.

- Dangerous Goods Number: 32198

- UN Number: 1293

- Packing mark: 7 Packing Category: Ⅲ

- Packing method: small opening steel drum; Plastic bottles or metal buckets (cans) outside wooden cases. Transportation precautions: summer should be transported in the morning and evening to prevent sunlight exposure. The transport runs on the prescribed route.

Regulatory information

- Regulations on the Safety Administration of Chemical Dangerous Substances (promulgated by The State Council on March 15, 2002);

- Rules for the Implementation of the Regulations on the Safety Management of Chemical Dangerous Substances (Hualofa (1992) No. 677)

- Measures for the Supervision and Administration of Fire Safety of Flammable and Explosive Chemicals (Promulgated by the Ministry of Public Security on 1994.3.24);

- Regulations on the Safe Use of Chemicals in the Workplace ([1996] Ministry of Labor Issue No. 423);

- General Technical Conditions for the Transportation and Packaging of Dangerous Goods (GB12463-90 published in 1990.9.7),

- Relevant provisions are made for the safe use, production, storage, transportation, loading and unloading of chemical dangerous goods.

- It is classified as a Class 3 flammable liquid by the Classification and Marking of Hazardous Chemicals (GB13690-92).

References:

- “Safety Manual of commonly used chemical Dangerous Goods”, “Practical Manual of Health and Safety of Toxic Chemicals”, “Chemical Substance Toxicity Book”, “Hazardous Chemical Safety Technology Book”.

- This product safety data guide is based on theoretical and experimental results of the company, and the data is provided for reference only.

- Date of filling: 2018-3-25

- Form filling department: R&D Department