Soft tube, hard tube

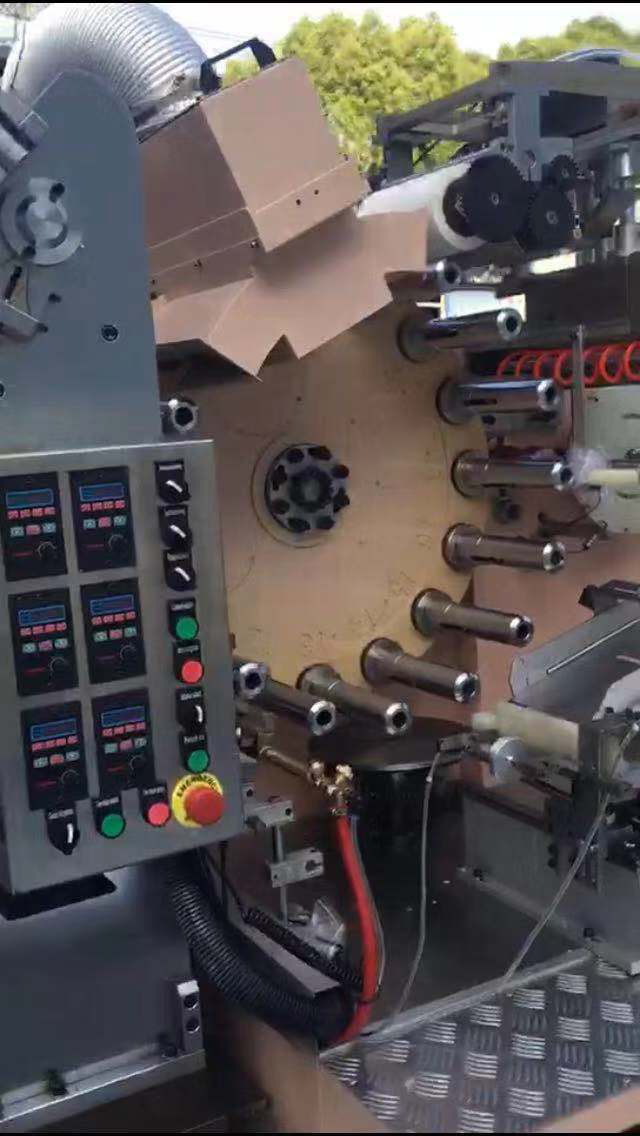

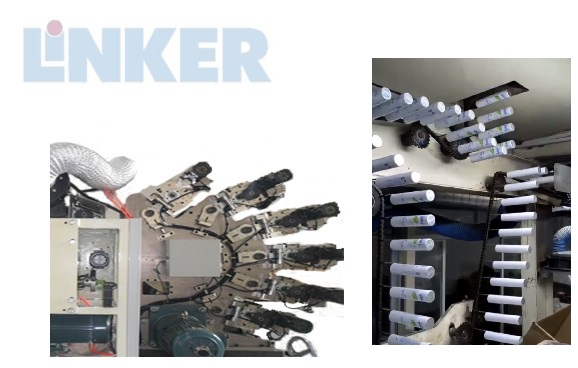

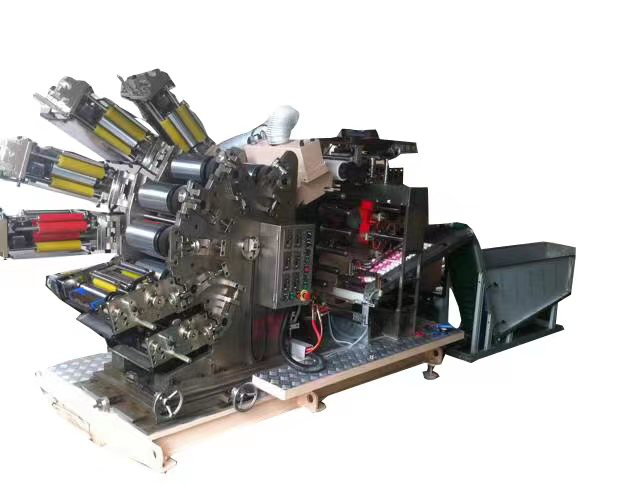

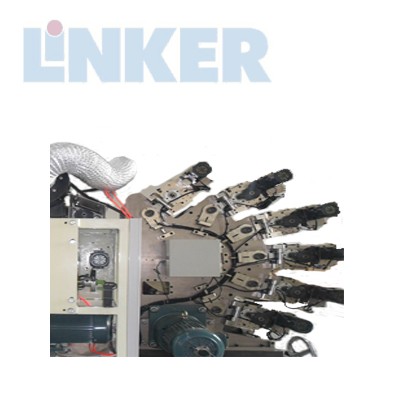

The Printer Header of the 6 Color Soft Tube Printing Machine

- Max Speed: 120pcs/minute (Depends on products)

- Color: 1-8 color, customization

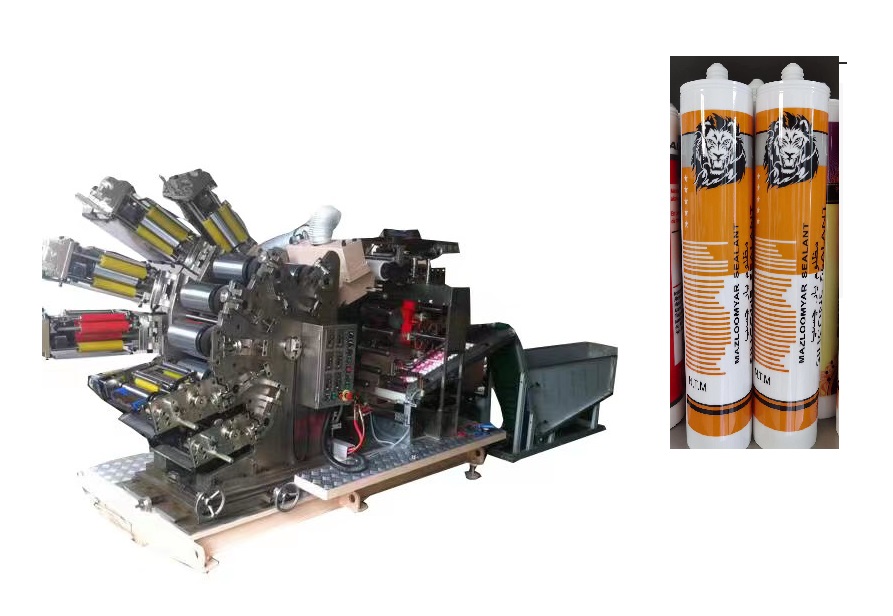

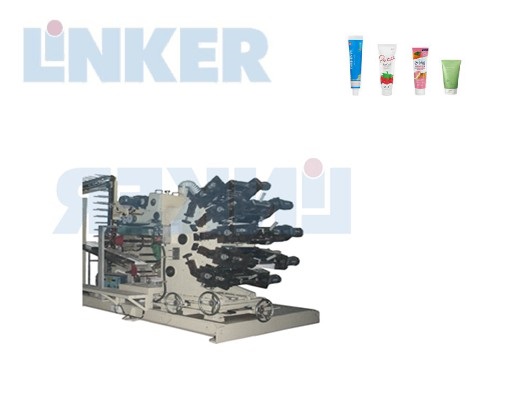

- Suitable for : Cosmetic tubes, Silicon Sealants, Aluminum Caps, Paper Cups

- Product Diameter Scope:10~120mm

- Motor Power: Driving Wheel 3.7kw; Driver for printing plate 2.2kw; driver chain 2.2kw; Driver for ink stick 0.06kw

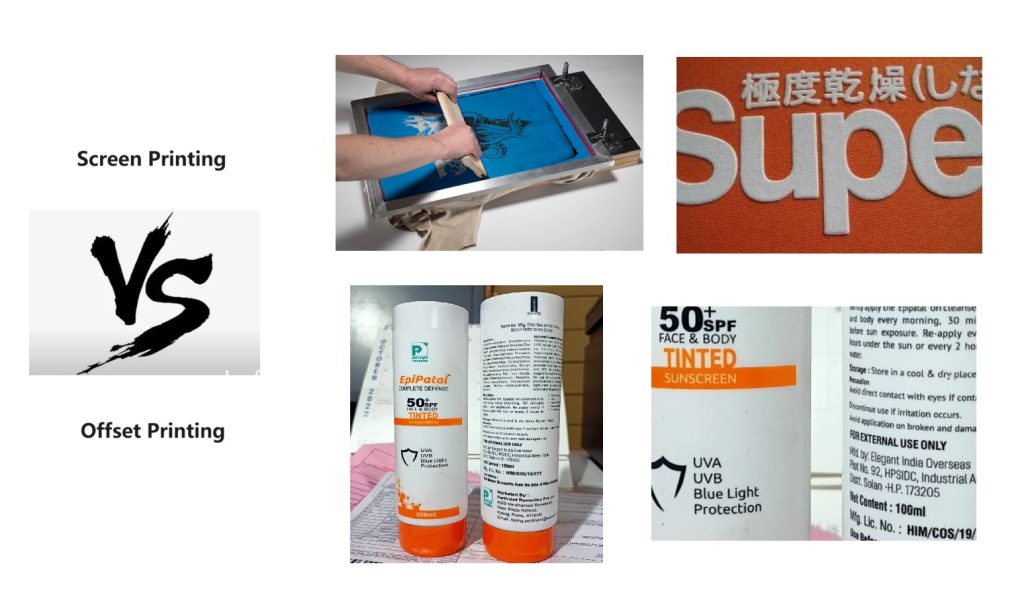

Applications– Sample of Offset Printer for sale

Description:

The header of the 6 color soft tube printing machine is produced by Shanghai Linker, which is very precise in printing can do really small words, even detect by the magnifier, the words still clear. Construction of the header of the 6 color soft tube printing machine .

We have accumulated rich design experience in the long-term practice for work, and thence are available to offer you the most reliable and the most economic magnetic agitator to help you to solve the most troublesome mixing problems.

1. Construction of the header of the 6 color soft tube printing machine

2. PE Soft tube auto-feeding system of the 6 color soft tube printing machine: Two types of PE soft tube auto-feeding system: with shoulders PE soft tube feeding system and without shoulders PE soft tube feeding system.

A. With shoulders PE soft tube feeding system : With shoulders PE soft tube feeding system can do feeding PE soft tube automatically, mechanical arm grab the shoulders of the soft tube and plug the soft tube onto the mandrel.

B. without shoulders PE soft tube feeding system Without shoulders PE soft tube feeding system is a mechanical arm to grab the PE soft tube without shoulders and feed them automatically onto the mandrel. It is a selective choice when factory need to produce the oval shape tube

3. Configurate selective choice for corona system and flaming system of the 6 color soft tube printing machine

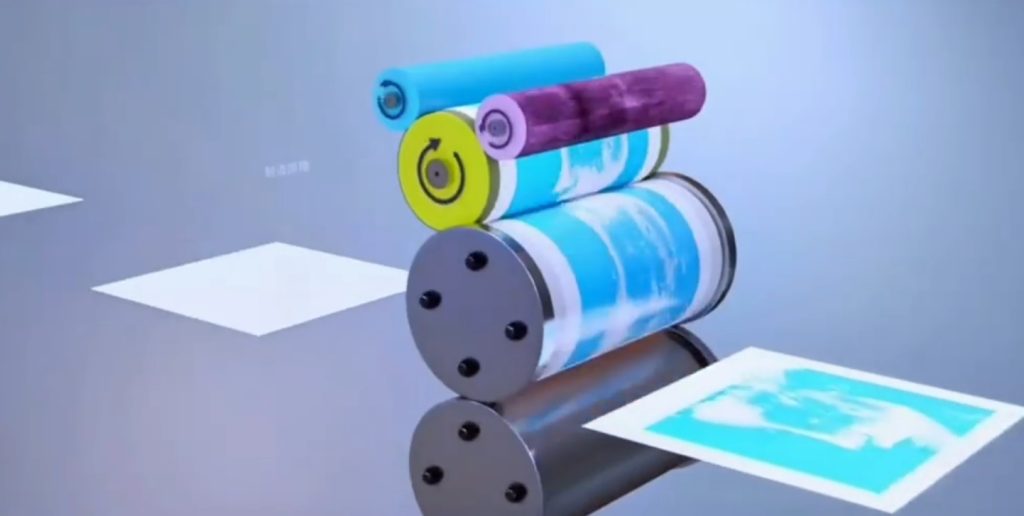

4. Printing system of the 6 color soft tube printing machine: 6 color printing system is consists of 6 printing axis in the header. The printing axis is the main factor that can ensure the precise of the printing. The technical how to adjust the printing axis will be trained when the machine bought by customer.

5. Varnish System of the 6 color soft tube printing machine: Varnish system is to doing varnish for PE soft tube, when soft tube finished printing, it will goes through the varnish system to finish varnish. Varnish have several kinds, UV varnish and other varnish, if UV varnish, we have to use the UV lamp in the oven to dry the UV varnish. If use other varnish, we can not use the UV lamp in the oven to dry the varnish, otherwise, the tube will comes out bent because of UV over cue.

6. The flaming system of the 6 color soft tube printing machine: Flaming system was embedded in the header of the machine. The function is similar with the corona system. Flaming system and corona system are selective choice, or customer can choose both of the two functions.

Printer Header Pictures