GREAT FEATURE

Best Dry Oven of 6 Color Printing Machine for Sale

- Max Speed: Speed adjustable according to printing head (Depends on products)

- Suitable for : Cosmetic tubes, Silicon Sealants, Aluminum Caps, Paper Cups

- Product Diameter Scope:adjustable

- Length: Can customize ( Silicon Sealants use short oven, cosmetic tube use long oven.)

Long and Short Oven

Lenth of oven can customize according to customer request

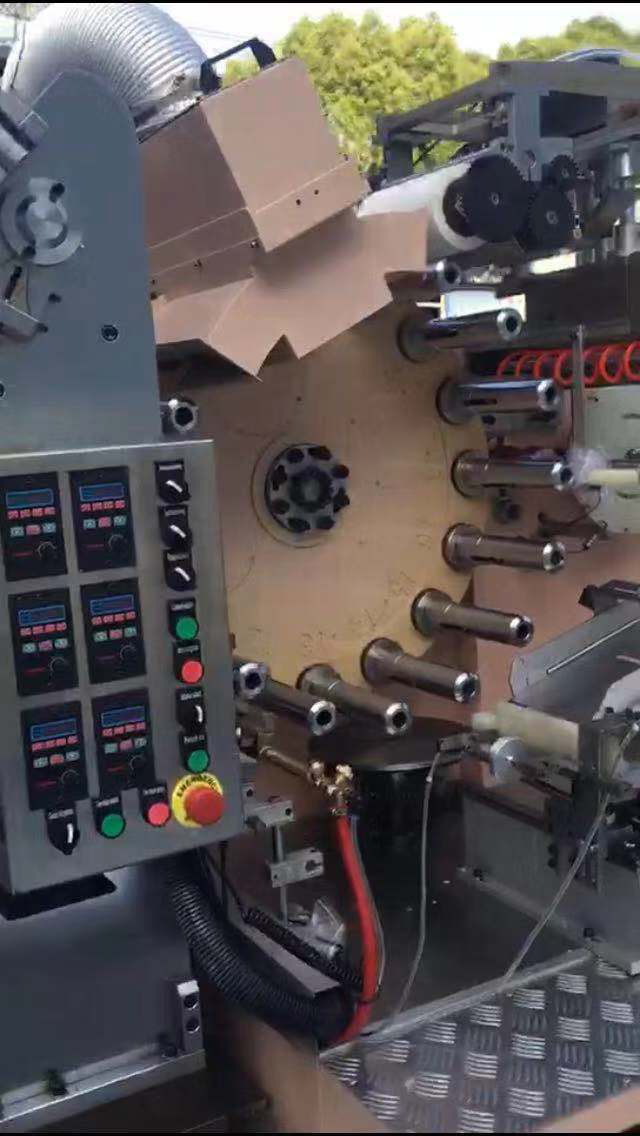

Header and Oven

Head + Oven =Whole set of 6 color printing machine.

Color can customize 2,4,6,8 color according to customer request.

Applications– Sample of Products

| Product dimension: | φ16-φ60mm 20-18-mm depend on products |

| Capacity: | 80-100pcs/min |

| Motor power for Driving wheel | 3.7KW-1pcs |

| Motor for printing plate | 2.2KW–1pcs |

| Motor for drive chain | 2.2KW-1pcs |

| Motor for driving ink stick | 0.06KW—6pcs |

| PrinterMainMotor | 7.5HP(5.5KW) |

| Cuttingsystemmainmotor | 3HP(2.2KW) |

| Roaster main motor | 3HP(2.2KW) |

| Driv emotor | 90W+90W+90W=270W=0.27KW |

| UV drying system | 10KW |

| Static eliminator system | 1.5KW |

| Roaster heating system | 1.2KW*4=4.8KW |

| Working air pressure | 0.4-0.8Mpa |

| Working voltage | 380V/420V Can customize any Voltage |

| External dimensions Printing head : | 3200*1600*1800mm |

| Drvingoven:3000kg | 9500*1000*2000mm |

| weight Printinghead: | 4000kg |

| weight Drying oven: | 3000kg |

| No | Name | Remark (maufacturer ) |

| 1 | Motor | Hanshin |

| 2 | frequency transformer | Panasonic |

| 3 | Gear | imported material |

| 4 | PLC | Mitsubishi |

| 5 | robot arm system | THK |

| 6 | Splitter | Japan |

| 7 | Clutch | Japan |

| 8 | Feeder System | THK |

| 9 | Transmission | Schneider |

| 10 | electronic control | Omoron |

| 11 | Bearing | Japan |

| 12 | Cylinder | Japan |

| 13 | voltage protector | France |

| 14 | low-voltage apparatus | France |

| 15 | Big Wheel | CNC |

| 16 | conveyor | Japan |

| 17 | Mandrel rods | imported material |

Video

Description:

Application of The oven of the 6 color printing machine: The function of oven is to dry the ink and varnish of the PE soft tube. This is closely related to the two systems of the oven, the hot wind dry system and the UV lamp drying system. The hot wind dry system is used to dry the ink, while the UV lamp drying system is used to dry the UV varnish. Oven normally is about 8 meters to 10 meters long, or the length customize according to customer request.

With our precious experience and professional knowledge, we will provide our best pre-sale and after-sale service for you.Work together with us, you will find enjoyable and successful business is so easy.

Application of The oven of the 6 color printing machine:

The function of oven is to dry the ink and varnish of the PE soft tube. This is closely related to the two systems of the oven, the hot wind dry system and the UV lamp drying system. The hot wind dry system is used to dry the ink, while the UV lamp drying system is used to dry the UV varnish. Oven normally is about 8 meters to 10 meters long, or the length customize according to customer request.

Numbers of the UV lamp drying system:

one UV lamp in the header of the 6 color printing machine, Two UV lamps in the oven of UV lap drying system. If customer has special request, factory can customize according to the special request. Numbers of the hot wind drying system: three hot wind drying system.

Printer Header Pictures

Oven Pictures & Spare Parts