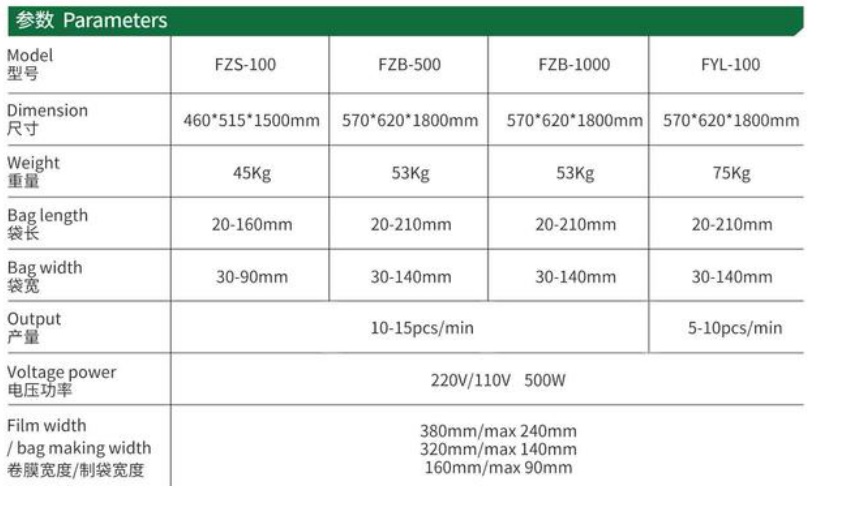

- Bag Length : 20-210mm;

- Bag Width: 30-140mm;

- Output: 5-15pcs/minute;

- Price: 2800USD.

Suitable for Plastic Roll Film

Product Information

What is 3 sides back Sealing Machine:

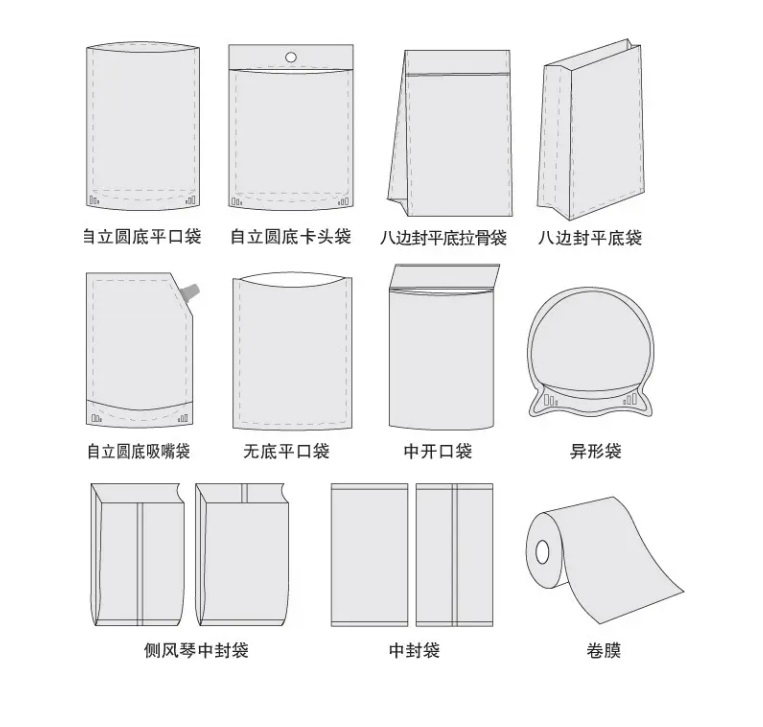

3 sides back Sealing Machine is used for packaging granule drugs, sugar, coffee, fruit, tea, MSG, salt, seeds and other fine particulate products equipment. Automatic particle packaging machine automatically completes all work such as measuring, bag-making, filling, sealing, printing batch number, cutting and counting; Automatically complete the packaging of fine particle materials. The three-side sealing bag making machine adopts PLC microcomputer control, double servo double frequency speed regulation, photoelectric monitoring and correction, pneumatic transmission and other technologies. It integrates the machine photoelectric in one, adopts automatic unwinding, cutting, tension adjustment control system, five rows of bridge type longitudinal sealing knife heat sealing and circulating water cooling bonding device, heating temperature Pc control, and can increase various special-shaped bag auxiliary bag making devices according to needs.

Application:

The three-side sealing bag making machine adopts PLC microcomputer control, double servo double frequency speed regulation, photoelectric monitoring and correction, pneumatic transmission and other technologies. It integrates the machine photoelectric in one, adopts automatic unwinding, cutting, tension adjustment control system, five rows of bridge type longitudinal sealing knife heat sealing and circulating water cooling bonding device, heating temperature Pc control, and can increase various special-shaped bag auxiliary bag making devices according to needs.

Technical Feature:

1, the whole machine adopts imported PLC, man-machine interface centralized control. Stable performance, easy to operate and maintain. The operation interface can be switched between Chinese and English.

2, all parameters are displayed by the man-machine interface in real time, can be preset bag-making speed, bag-making length, temperature, counting, finished product transportation, etc.

3, LPC automatic correction, double photoelectric tracking feed, automatic constant tension control AC frequency conversion constant speed automatic feed.

4, imported double servo drag control.

5, the upper and lower sealing pressure AC variable frequency motor drive.

6, the temperature is adjusted by PID, 0 ~ 300℃ adjustable, contactless automatic control, human-machine interface centralized setting.

7, the temperature is centrally controlled by the computer.

8, pneumatic multi-function automatic punching, automatic collection of side material cutting, with electrostatic elimination device.

9, working mode: fixed length bag, photoelectric tracking bag.

10, punching method: can be set continuous, interval, stop, stamping time can be preset.

11, times the way: one to six times the delivery.

Batch delivery function: The workbench has a batch delivery function, and the number of batches can be preset.

Technical parameters:

(1) Check whether the specifications of the container cup and bag maker are in line with the requirements before opening the particle automatic packaging machine.

(2) Use the hand to dial the main motor belt to see whether the machine is flexible, and when it is confirmed that the machine has no abnormal conditions, it can be powered on.

(3) Under the machine, the packaging material is installed between the two paper wheels, and the machine is placed in the slot of the paper arm plate. The paper wheel should clamp the core of the material installed, so that the packaging material is aligned with the bag maker, and then the knob on the stop sleeve is tightened, and the printing surface is to the front or the composite surface (i.e. the polyethylene surface) is to the back. After starting up, adjust the axial position of the packaging material on the paper holder wheel according to the paper feeding condition to ensure the normal paper supply.

(4) Turn on the main power switch of the particle automatic packaging machine, press down the clutch handle, so that the measuring mechanism is separated from the main drive, turn on the start switch, and the machine runs empty.

(5) If the conveyor belt rotates clockwise, it should be stopped immediately, and the main motor is reversed at this time, and the belt is turned counterclockwise after the motor is reversed.

(6) Set the temperature, according to the packaging material used, set the heat sealing temperature on the temperature controller of the electric control box.

(7) Bag length adjustment Insert the packaging material into the bag maker according to the relevant regulations, clamp between the two rollers, turn the roller, pull the packaging material below the cutting knife, after reaching the set temperature for 2 minutes, switch on the start switch, loosen the lock nut of the bag length adjustment screw, adjust the bag length controller knob, turn clockwise to shorten the bag length, vice versa, after reaching the required bag length, Tighten the nut.

(8) Determine the position of the cutter, when the bag length is determined, remove the cutter, switch on the starting switch to continuously seal several bags, when the heat sealer has just opened, before the roller has not pulled the bag, immediately stop. Then move the left cutter first, align the knife edge with the middle of the transverse sealing path of integer times the bag length (generally 2 to 3 times the bag length), and make the blade perpendicular to the straight paper direction, tighten the fastening screw of the left cutter, lean the right cutter on the left cutter, and let the knife tip to the knife tip after laying flat, slightly tighten the fastening screw in front of the stone cutter, and press the back of the right cutter down. So that there is a certain pressure between the two knives, tighten the fastening screw behind the right knife, put the packaging material between the blade, slightly down the front of the right knife, to see whether the packaging material can be cut off, otherwise it should continue to be not cut until it can be cut off, and finally tighten the front screw.

(9) When stopping, the heat sealer must be in an open position to prevent burning the packaging material and extend the service life of the heat sealer.

(10) When rotating the measuring disc, it is not allowed to turn the measuring disc in the clockwise direction. Before starting the machine, check whether the feeding doors are closed (except the feeding doors in the open state), otherwise the parts may be damaged.

(11) Metering adjustment When the metering weight of the packaging material is less than the required weight, the adjustment screw of the metering disk can be adjusted clockwise to achieve the required packaging amount, and the reverse if it is greater than the required weight.

(12) After the charging operation is not abnormal, the machine can work normally, turn on the counter switch, you can complete the counting work, and finally install the protective cover.

Sachet machine granule filling:

Sachet granule filling machine suitable for many granule materials: Pistachio packing machine is suitable for small bag packing of pellets. Suitable for the production of granular drugs, sugar, coffee, fruit, tea, MSG, salt, seeds, desiccant and other fine particle manufacturers. It can automatically complete the procedures of measuring, bag-making, filling, sealing, cutting, printing production date, cutting easy tearing and so on. Pistachio, also known as must answer, green Renren fruit and so on.

Semi automatic granule filling machine:

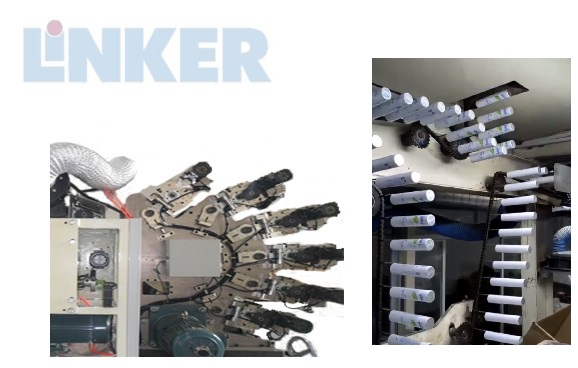

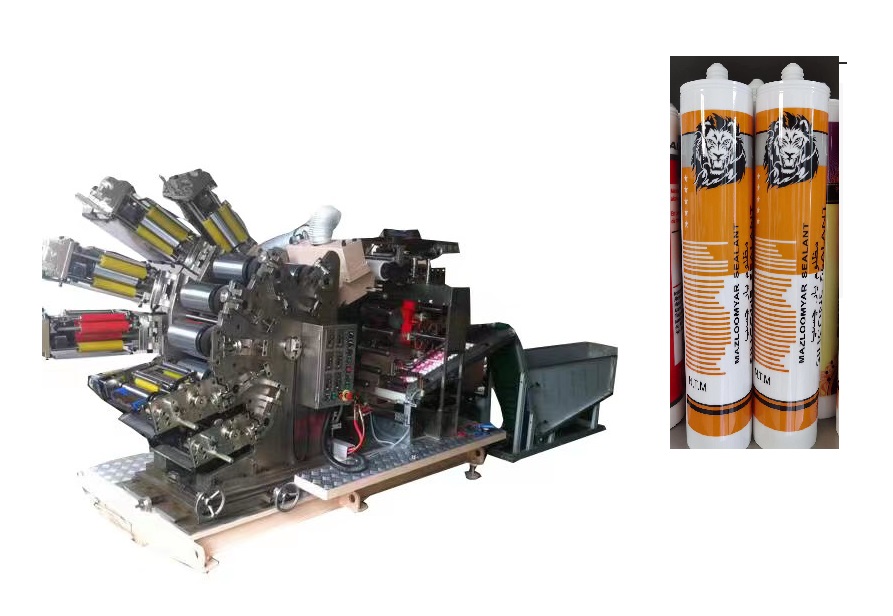

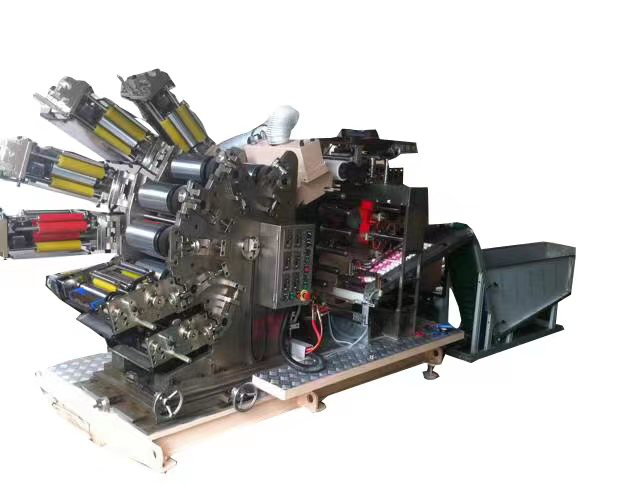

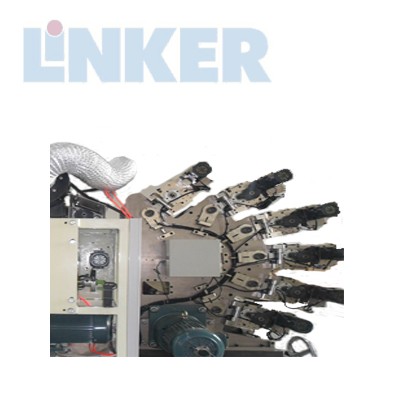

LINKER producing and selling many Semi automatic granule filling and machine also the automatic type granule filling machine, welcome to tell us your capacity and material type for quotation.

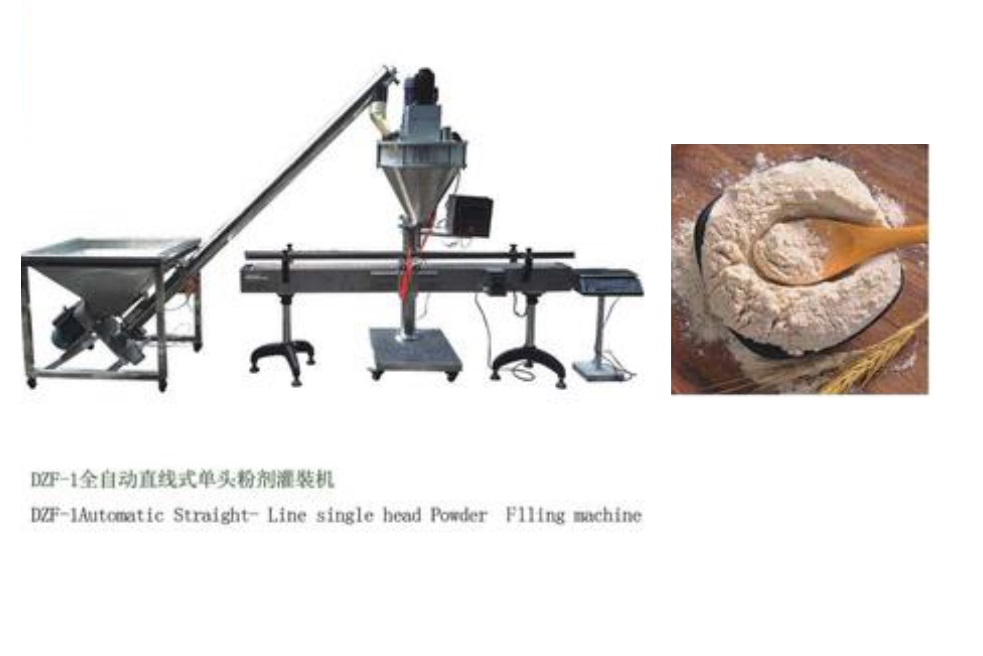

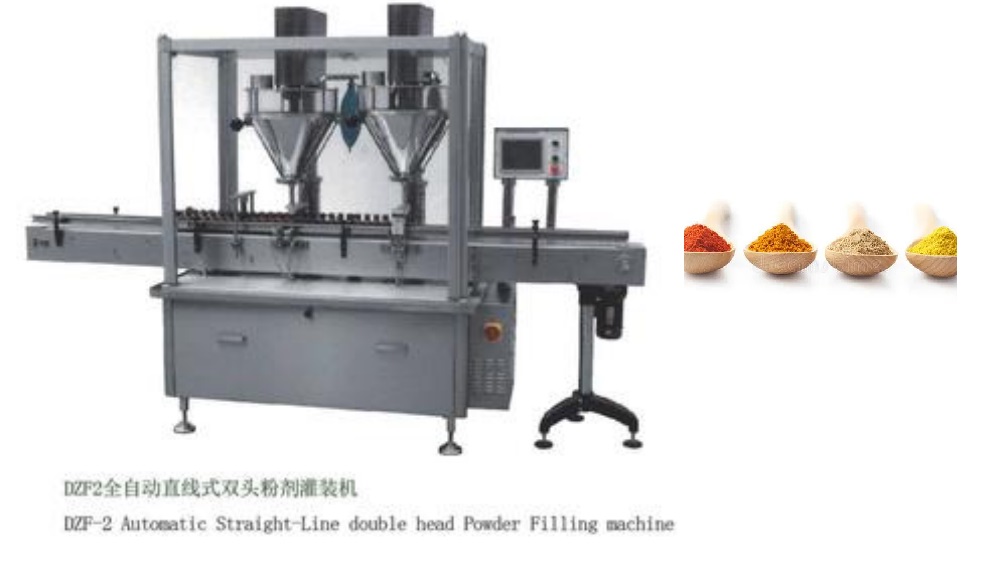

Powder Filling Machine:

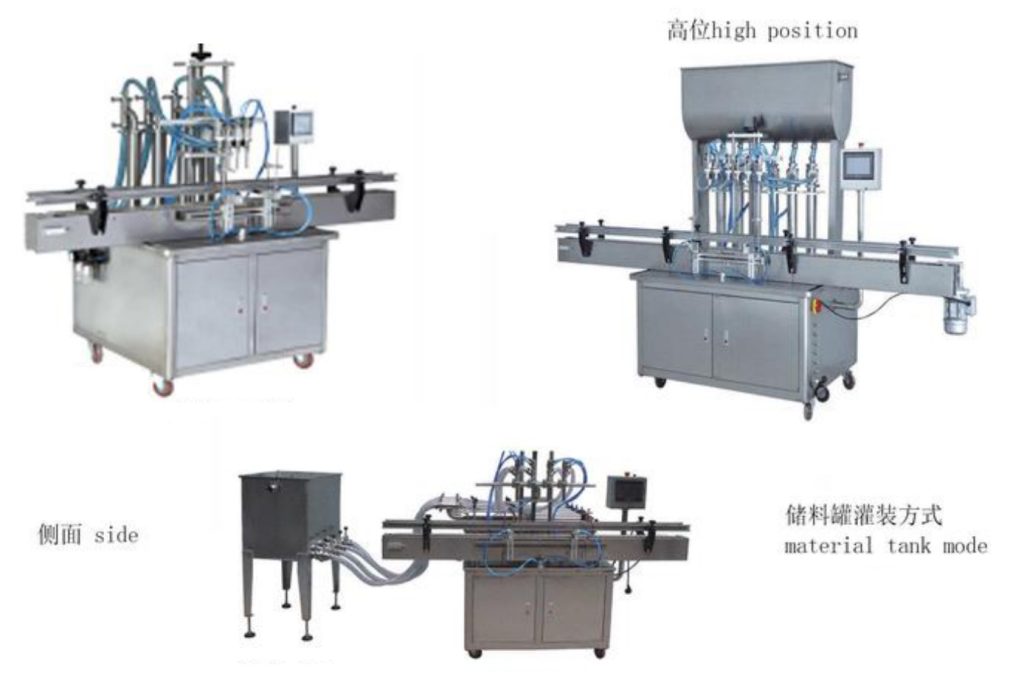

Powder, Liquid, Paste, Granule filling machine Customization:

We have various types of Granule filling machine for sale, and we do customization according to customer’s speed and capacity. We can also design and produce the whole production line including the grinder , Blending machine, drying machine, conveyor, feeder, vibrating Screen, Packing Machine… Please contact us quotation, parameters and price.

LYLK Pneumatic Filling Machine

LYLK Filling and Stoppering machine

LYLK Filling and Capping Machine

LYLK Servo Filling Machine

LYLK Automatic filling and sealing machine

Customize Granule filling machine According to your Capacity:

We can customize Granule filling machine connect with your production line (the dimension and width of feeder).

Videos of Filling Machine :

We have many model of Powder, Liquid, granule, paste Filling and Capping Machine , here show some examples:

Production Line Customization Solution:

We can customize whole automatic production line according to customer special request. According to your special material, capacity requirement and motor and electric cabinet certification requirement, we can customize semi-auto or fully automatic production line for our customer. Please contact us for detail proposal and quotation.

Air Below Washing Machine + Sterilize Machine + Filling Machine + Metal Detector + Check Weight + Capping Machine Sealing Machine + Labeling Machine + Label Shrink Film

Drying Machine + Grinding Machine + Sifter Machine + Mixing Machine + Packing Machine:

Factory Information

Factory Information

| Business Type: | Manufacturer/Factory | Main Products: | Mill, grinder, granulator, mixer, Crushing Equipment |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000 Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

Certifications:

Machine Packing:

Small machine packed with export fumigation-free wooden cases, goes with bulk shipment or in container.

Installation:

- The machine is installed according to the instructions after unpacking, and the compressed air source is connected. If the air source pressure is 0.6MPa, the valve should be installed first in the compressed air main pipeline.

2, open the right door to turn out the oil mist oil label to add clean special oil, or sewing machine oil, note: when the fuel can not be with air pressure, the oil amount of about 8 minutes full is appropriate.

3, the intake air source check whether the sealing surface is leaking, adjust the air pressure to 0.3~0.4MPa to adjust the oil intake, generally spray a drop of oil after several times, regularly check the oil injection.

4, filling volume adjustment: first rotate the filling volume adjustment hand wheel, observe the indicator window scale, so as to achieve the required amount of filling, at the same time adjust the suction, discharge speed to achieve satisfactory filling effect, the dosage standard measure the filling amount, and finally correct the filling amount.

Warranty of Machine:

We provide one year warranty for all our machine, but not including the man-made damage. We can provide free spare parts if damage in one year in normal operation. 24hours stand by to solve urgent problems. 3 days of spare parts provide by express. Please specially notice for the motor connection. it should be connect in right way to prevent the motor burnt, take special notice of running machine safely. Machine need to be clean and maintained frequently.

Maintenance of machine:

Servo filling machine as an important equipment in the automated production line, its maintenance is very important to ensure production efficiency and product quality. The following is an overview of the general servo filling machine maintenance procedures:

Routine maintenance

Cleaning and inspection:

Before and after each shift, clean the external surface of the servo filling machine, especially the working area and transmission components.

Check for debris and foreign objects around the machine and keep the working environment clean and tidy.

Lubrication:

According to the requirements of the equipment manual, regularly fill the lubricating parts of the servo filling machine with appropriate lubricating oil or grease.

Be careful not to over-lubricate or leak to avoid contaminating the product.

Check the transmission components:

Regularly check the tension and wear of the drive belt, chain and gear, and adjust or replace damaged parts in time.

Cleaning and replacing filters:

Regularly clean or replace the servo filling machine air filter, hydraulic filter, etc., to ensure the smooth system and reduce the failure rate.

Scheduled maintenance

Electrical parts inspection:

After powering off the device, check that electrical connections, switches, control panels, and sensors are secure and working properly.

Check cable and wiring wear regularly to avoid short circuit or open circuit.

Pneumatic system maintenance:

Check the working condition of pneumatic components, cylinders and solenoid valves to ensure that the gas path is smooth and there is no leakage.

Servo system calibration:

According to the requirements of the equipment manual, the servo system is calibrated and adjusted regularly to ensure the running accuracy and stability.

Spare parts replacement:

According to the service life of the equipment and the depletion of spare parts, timely replacement of vulnerable parts and key components, such as seals, valves, etc.

Performance test:

Regularly carry out the performance test and function test of the servo filling machine, confirm whether the functions are normal, adjust the parameters and control logic.

Emergency handling

Troubleshooting:

If the device is faulty or abnormal, shut it down immediately and handle it according to the troubleshooting guide in the device manual.

Maintenance records:

Record the specific content, time and operator of each maintenance, and establish maintenance files to facilitate traceability and analysis of equipment operating conditions.

By strictly implementing the above maintenance procedures, the reliability and stability of the servo filling machine can be improved, the service life of the equipment can be extended, and the continuous operation of the production line and the stability of product quality can be ensured.

FAQ

We are factory located in Shanghai China, welcome to visit our team.

1. Normally 30% deposite payment, balance 70% before shipment.

2. We can provide L/C for special country.

1. For some simple machine, we will install before shipment, no need to do complicate install on customer side.

2. For complicate machine, our engineer is available for going customer side, but the visa fee, round flight ticket, hotel and food are undertaken by customer. Besides, engineer compensation 100USD/Day. Engineer can provide installation services, and also available to teach your operator how to use it.

1. Talk with our sales about your product size and applications, capacity you need per minute, For example 50 pcs/minute. we will provide the right mode for you.

2. Place Order and do the first Payment.

3. Produce and send video for your green light.

4. You do the final Payment

5. Arrange shipment

6. Receive goods.